Plasma treatment device and wafer transportation tray

A processing device and plasma technology, which is applied in the direction of plasma, semiconductor/solid-state device manufacturing, discharge tube, etc., can solve problems such as troublesome operation, reduced adhesion between the tray for wafer transfer and the support body, etc., to reduce loss and reduce mechanical The effect of permanent movable parts and efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

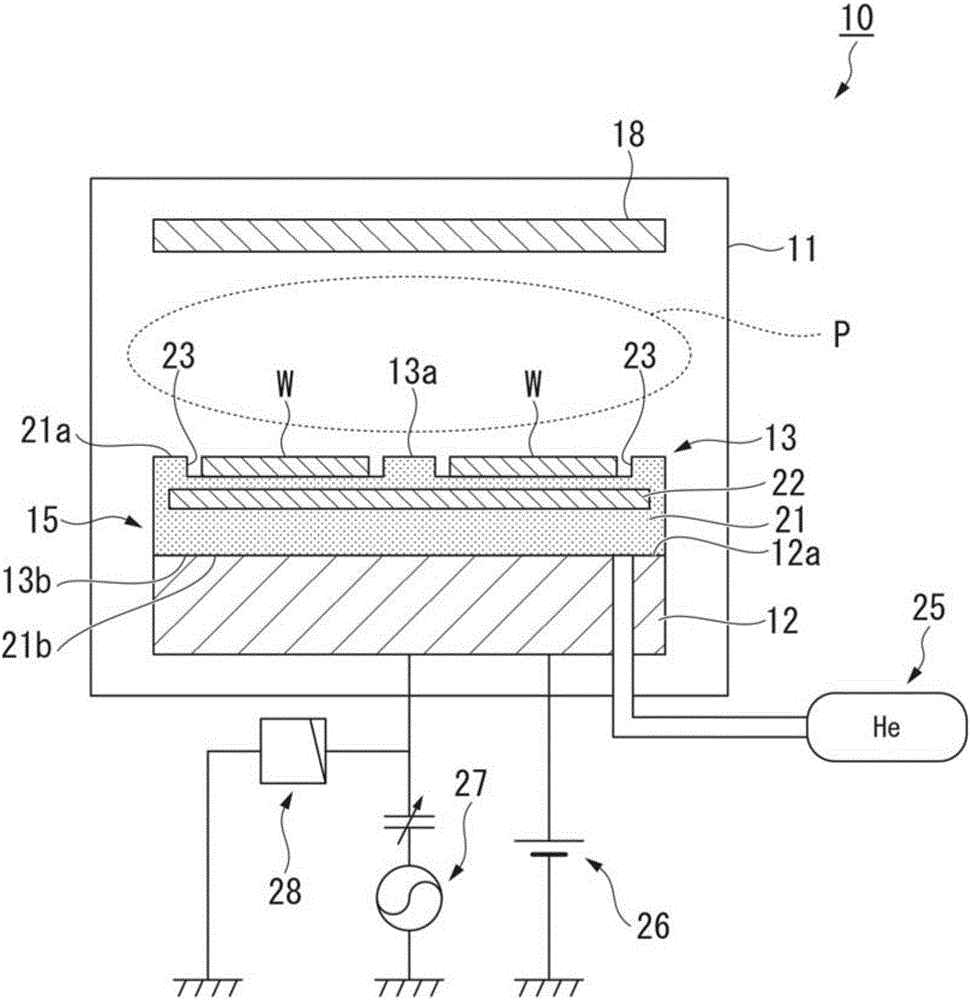

[0035] figure 1 It is a sectional view showing the whole plasma processing apparatus according to the first embodiment of the present invention.

[0036]The plasma processing apparatus 10 includes: a plasma processing tank (chamber) 11; an upper electrode 18 disposed near the upper surface inside the plasma processing tank 11; a support body 12 disposed near the bottom surface inside the plasma processing tank 11, And the lower electrode is formed; and the supporting part 15 has the tray 13 for wafer transfer placed on the supporting body 12 .

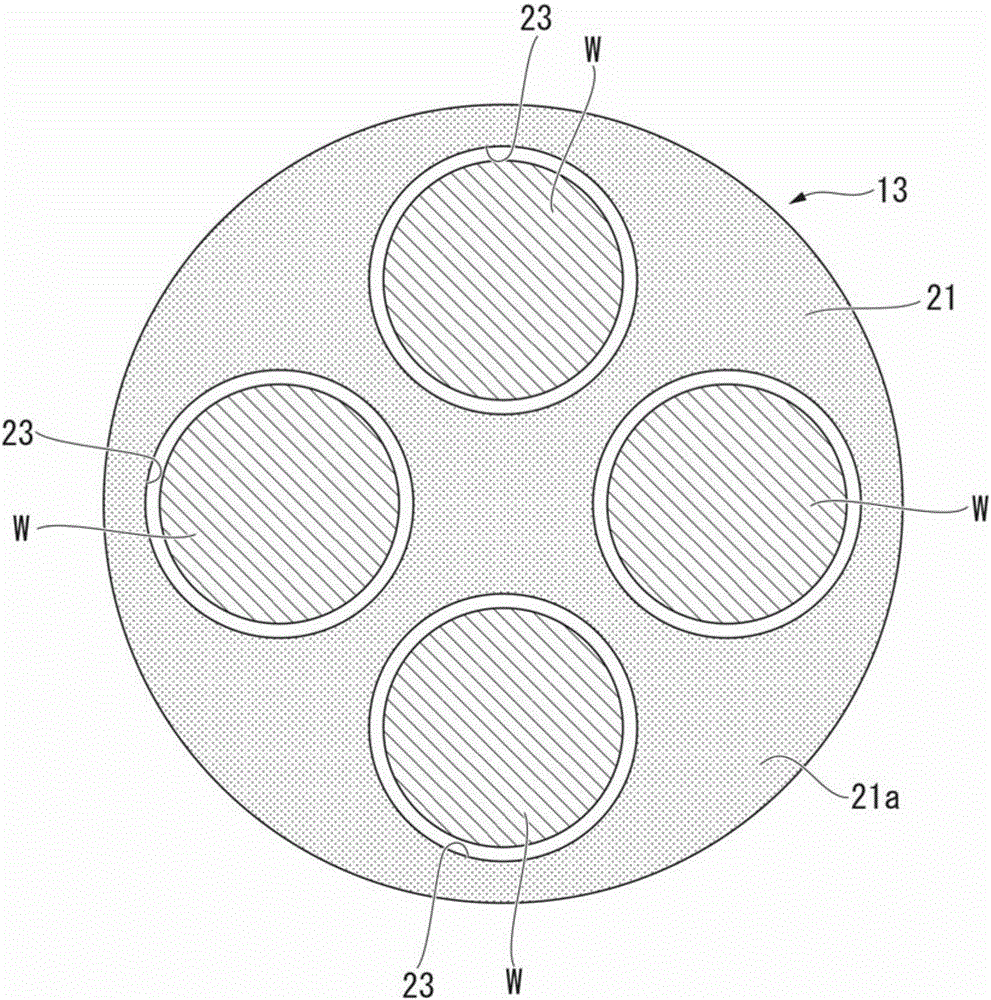

[0037] The tray 13 for wafer transfer has: a substantially disk-shaped base 21; ) The position of 21a. Further, on one surface 21a of the base body 21, a concave portion 23 for inserting a wafer W which is an object to be processed is formed.

[0038] Substrate 21 has a resistance value of 10 8 More than Ω and 10 11 It is composed of a high resistance body in the range of Ω or less.

[0039] Such a high resistance body may be, fo...

no. 2 approach

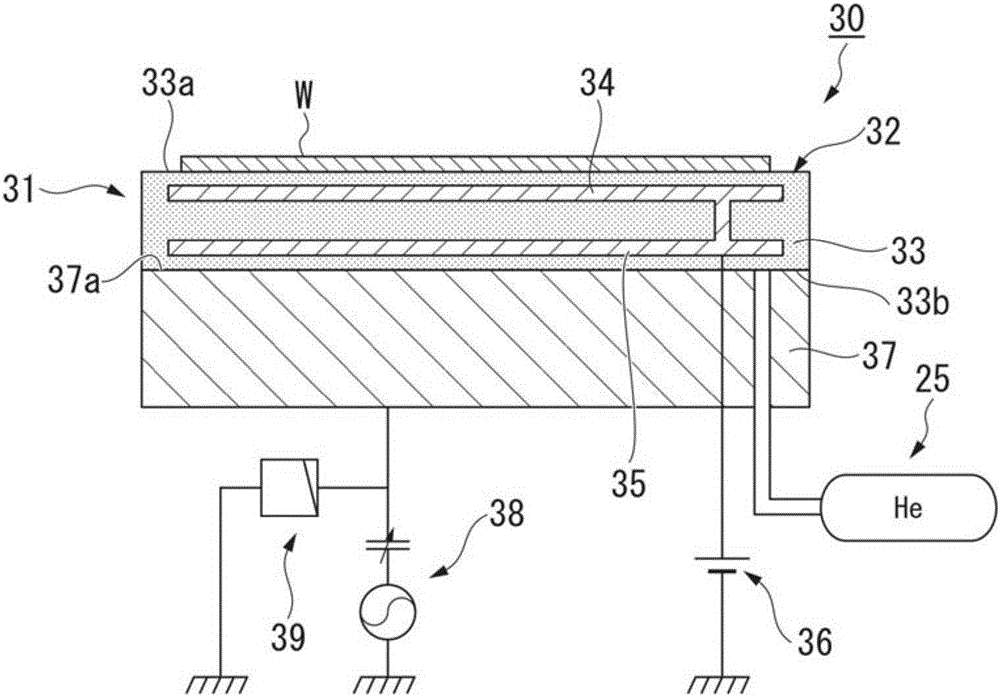

[0063] image 3 It is a cross-sectional view showing the vicinity of the support portion of the plasma processing apparatus according to the second embodiment of the present invention.

[0064] The wafer transfer tray 32 in the support portion 31 of the plasma processing apparatus 30 according to the second embodiment includes: a base 33 formed of an insulator; The other surface 33b is closer to the position of one surface (first surface) 33a; and the second conductive layer 35 for electrostatic adsorption is embedded in the position of the substrate 33 closer to the other surface (second surface) 33b than the one surface 33a. .

[0065] The base body 33 is made of, for example, a ceramic plate or the like. The first conductive layer 34 and the second conductive layer 35 are electrically connected by a conductor extending in the thickness direction of the wafer transfer tray 32 .

[0066] The first conductive layer 34 and the second conductive layer 35 are made of metals su...

no. 3 approach

[0083] Figure 4 It is a sectional view showing the vicinity of the support portion of the plasma processing apparatus according to the third embodiment of the present invention.

[0084] The tray 42 for wafer transfer in the support portion 41 of the plasma processing apparatus 40 according to the third embodiment has: a base 43 formed of an insulator; The other surface 43b is closer to the one surface (first surface) 43a; and the conductor 45 is disposed so as to be exposed on the other surface (second surface) 43b of the base body 43 .

[0085] The base body 43 is made of, for example, a ceramic plate or the like. The first conductive layer 44 and the conductor 45 are made of metals such as aluminum, tungsten, titanium, or alloys containing these metals. The first conductive layer 44 may be formed, for example, at a position several millimeters deep from the one surface 43 a of the base 43 so as to extend parallel to the one surface 43 a of the base 43 .

[0086] Such a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com