Electric arc wire filling additive manufacturing method for inclined thin-walled structural part

A thin-walled structural part and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of inability to form the inclination angle to determine the offset of the welding torch, unsuitable for multi-layer single-channel inclined thin-walled structural parts, etc., to overcome the flow of molten pool. Problems, effects that are easy to automate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

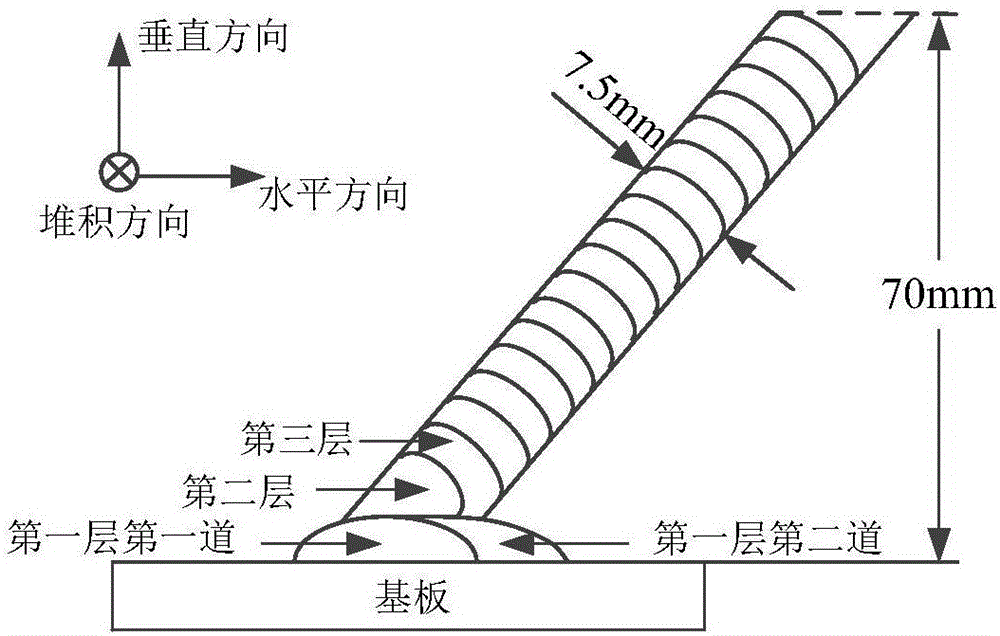

[0027] Such as figure 1 As shown, the high-strength steel straight wall structure is a multi-layer single-channel structure. The height of the structure is 70mm, the width is 7.5mm, and the length is 150mm. The angle between the straight wall structure and the base plate is 45°. The arc-filling additive manufacturing equipment is Panasonic YD-500FR power supply, the ABB robot is used as the motion mechanism, and the welding torch is fixed on the end of the sixth axis of the robot. Arc wire filling additive manufacturing parameters: stacking current 150A, stacking speed 5mm / s, when the angle between the structural part and the substrate is 90°, the stacked layer height h is 1.66mm, and the protective gas used in the stacking process is 95% Ar+5% CO 2 The filler wire is CHW-55CNH high-strength weather-resistant steel welding wire with a diameter of 1.2mm. The size of the Q235 substrate is 200mm×120mm×10mm. The welding torch is fixed at the end of the sixth axis of the robot or o...

Embodiment 2

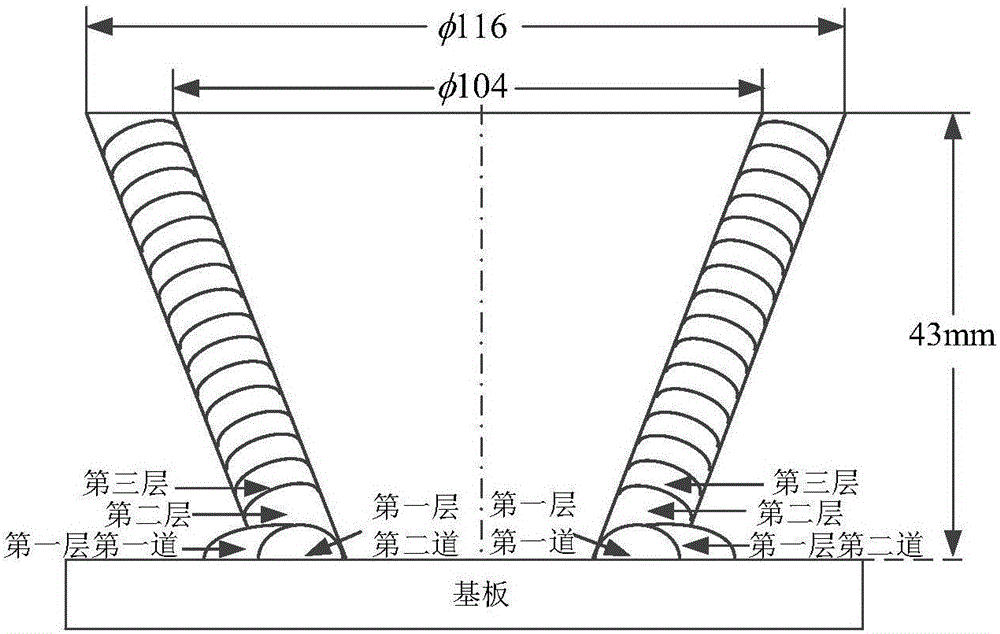

[0034] Such as figure 2 As shown, the high-strength steel ring structure is a multi-layer single-track structure with a height of 43mm and a width of 6mm. The center radius of the ring structure is 55mm, and the cross section of the ring structure is 60° from the base plate. The arc-filling additive manufacturing equipment is Panasonic YD-500FR power supply, the ABB robot is used as the motion mechanism, and the welding torch is fixed on the end of the sixth axis of the robot. The stacking process parameters of high-strength steel circular thin-walled structural parts are: stacking current 120A, stacking speed 5.3mm / s, when the angle between the structural part and the substrate is 90°, the stacking layer height h is 1.44mm, and the protective gas used in the stacking process is 95 %Ar+5%CO 2 , The filler wire is CHW-55CNH high-strength weather-resistant steel welding wire, the diameter of the wire is 1.2mm, and the size of the Q235 substrate is 200mm×150mm×10mm. The weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com