Anti-fogging film and preparation method thereof

A technology of anti-fog film and anti-fog layer, applied in the direction of film/sheet adhesive, adhesive, etc., can solve the problems of affecting the normal growth of plants, affecting the sunlight intake of plants in the shed, fogging, etc., and achieve good mechanical Processability and thermal stability, outstanding anti-fog effect, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

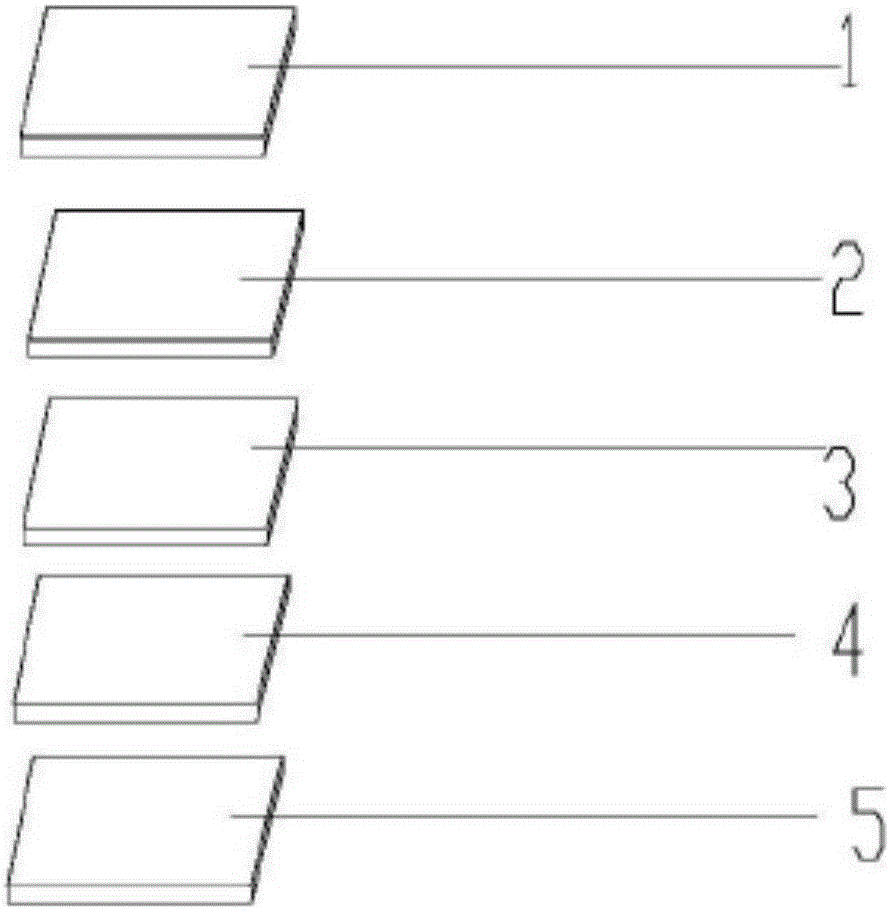

[0024] Such as figure 1 As shown, an anti-fog film includes: a PET substrate 3, an anti-fog layer 2 is provided above the PET substrate 3, the thickness of the anti-fog layer 2 is 20 μm, and an anti-fog layer 2 is provided above the anti-fog layer 2 Protective film 1, the thickness of the protective film 1 is 25 μm, the bottom of the PET substrate 3 is bonded with the release paper 5 through the adhesive layer 4, and the thickness of the release paper 5 is 20 μm, wherein the The anti-fog layer 2 consists of the following raw materials in parts by weight:

[0025] 0.5 parts of nano titanium dioxide, 5 parts of polyurethane acrylate.

[0026] The PET substrate 3 is a PET polyester film with a thickness of 40 μm.

[0027] The adhesive layer 4 is common pressure-sensitive adhesive.

[0028] Preparation:

[0029] 1) Take nano-titanium dioxide and polyurethane acrylate, stir evenly, and control the stirring temperature not to be higher than 30°C to obtain a mixture;

[0030] 2)...

Embodiment 2

[0034] Such as figure 1 As shown, an anti-fog film includes: a PET substrate 3, an anti-fog layer 2 is arranged above the PET substrate 3, the thickness of the anti-fog layer 2 is 10 μm, and an anti-fog layer is arranged above the anti-fog layer 2 Protective film 1, the thickness of the protective film 1 is 35 μm, the bottom of the PET substrate 3 is bonded with the release paper 5 through the adhesive layer 4, and the thickness of the release paper 5 is 30 μm, wherein the The anti-fog layer 2 consists of the following raw materials in parts by weight:

[0035] 0.5 parts of nano titanium dioxide, 3.5 parts of polyurethane acrylate.

[0036] The PET substrate 3 is a PET polyester film with a thickness of 20 μm.

[0037] The adhesive layer 4 is common pressure sensitive adhesive or resin type pressure sensitive adhesive.

[0038] Preparation:

[0039] 1) Take nano-titanium dioxide and polyurethane acrylate, stir evenly, and control the stirring temperature not to be higher t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com