Internal combustion engine variable valve timing mechanism with simple structure

A valve timing and simple structure technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of complex structure of the variable valve timing mechanism, and achieve the effect of simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

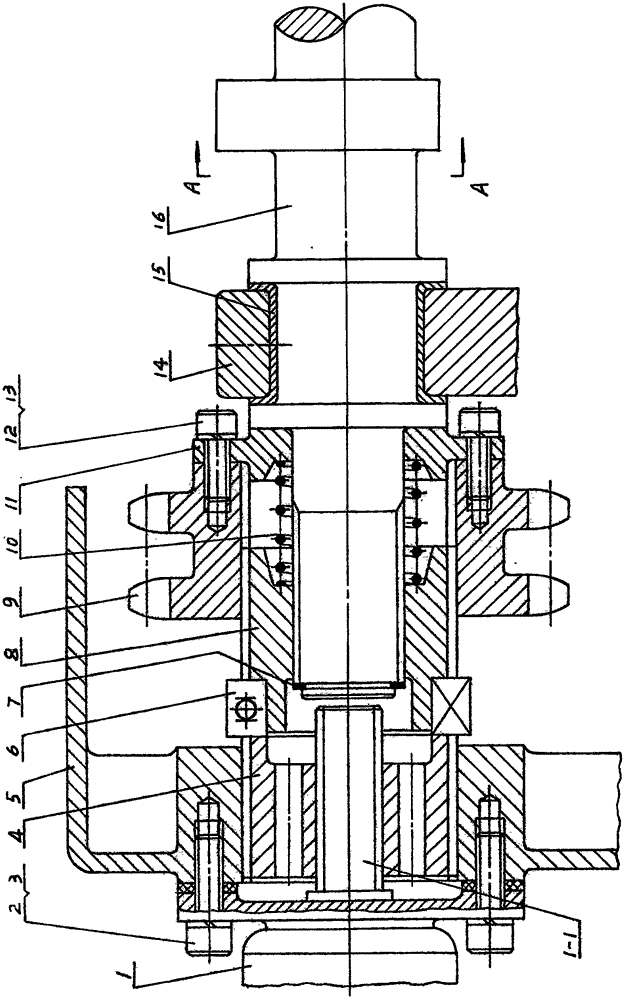

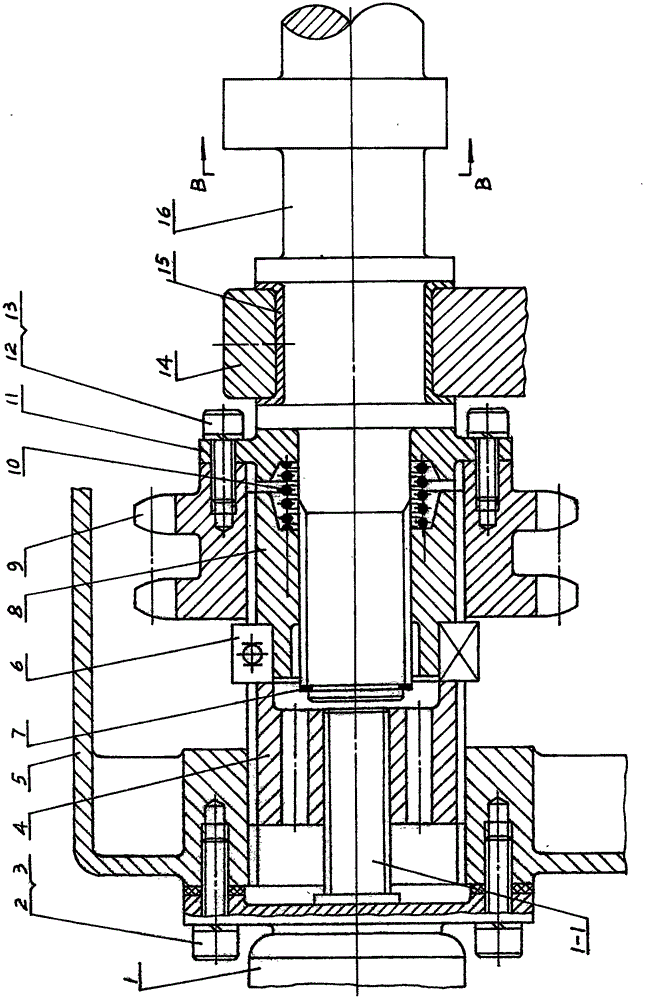

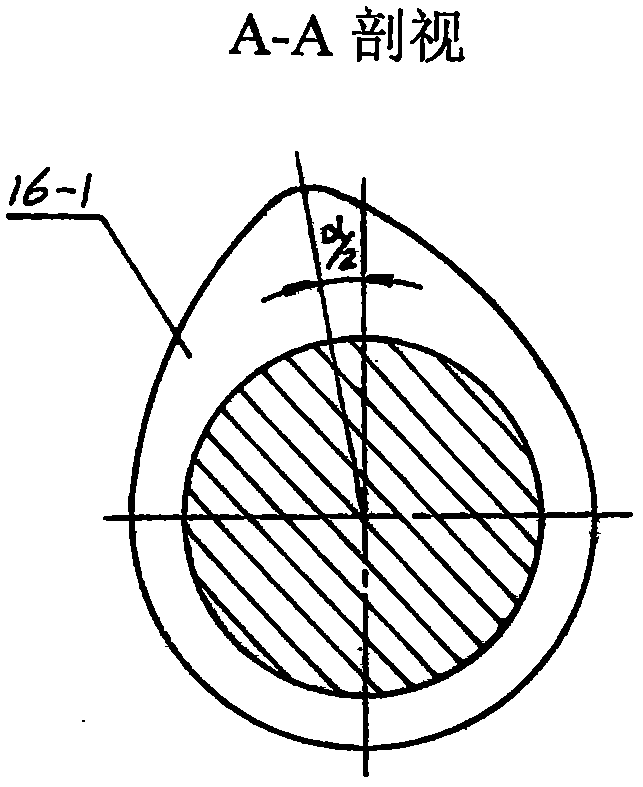

[0010] Specific implementation mode one: combine Figure 1 to Figure 15 Illustrate the specific embodiment, the present embodiment comprises a stepper motor (1), a sliding sleeve 1 (4), a dust cover (5), a one-way thrust ball bearing (6), a shaft circlip ( 7), a sliding sleeve II (8), a sprocket (9), a return spring (10), an end cover I (11) and a camshaft (16); put the stepper motor (1) The threaded shaft (1-1) is combined with the internal thread (4-2) of the sliding sleeve I (4) and packed into the straight-tooth internal spline (5-1) of the dust cover (5), and then the bolt (2 ) and spring washer (3) to fix the stepper motor (1) on the dust cover (5), and the sprocket (9) and end cover I (11) are fixed together with bolts (12) and spring washer (13) Finally, install the root of the straight-toothed external spline (16-2) of the camshaft (16), and then install the return spring (10) and sliding sleeve II (8) in sequence, and limit the position with the elastic circlip (7) ...

specific Embodiment approach 2

[0011] Specific embodiment two (applicable to the internal combustion engine of cylinder annular arrangement): combine Figure 16 ~ Figure 33Illustrate the specific embodiment, this embodiment comprises a stepper motor (1), a sliding sleeve III (18), a cylinder head cover (17), a one-way thrust ball bearing (6), a shaft circlip ( 7), a sliding sleeve IV (19), an intake convex plate (20), an exhaust convex plate (21), an end cover II (22) and a bevel gear central shaft (27); The threaded shaft (1-1) of the motor (1) is combined with the internal thread (18-1) of the sliding sleeve III (18) and put into the straight-tooth internal spline (17-2) of the cylinder head cover (17), Fix the stepper motor (1) on the cylinder head cover (17) with bolts (2) and spring washers (3), and put the exhaust convex plate (21) into the straight tooth outer flower of the bevel gear central shaft (27) key (27-1), then fix the air intake convex plate (20) and end cover II (22) together with bolts (...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap