Metal die 3D printing laser micro-region treating method

A metal mold and processing method technology, applied in the field of metal mold 3D printing laser micro-area processing, can solve the problems of high labor intensity of operators, waste of metal powder materials, and low surface treatment performance, so as to reduce labor intensity and processing costs, The effect of shortening processing and manufacturing work time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

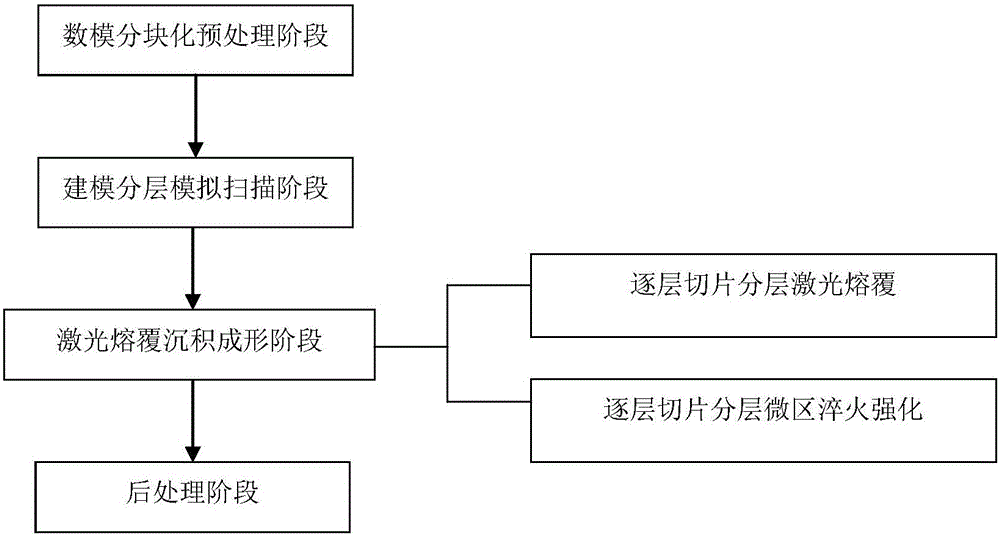

[0020] Attached below figure 1 The specific steps of the laser micro-area processing method for 3D printing of a metal mold of the present invention are described in detail.

[0021] The method for processing a metal mold 3D printing laser micro-area of the present invention includes the following steps:

[0022] 1) Blocking pretreatment stage of the digital mold: According to the design requirements of the metal mold size, the digital mold of the metal mold to be made is divided into two types: ①The first type: this part of the base material Carry out milling to produce a preset cavity structure, and use acetone to wipe and remove oil and smooth the cavity structure. The length, width and thickness of this part of the substrate are 1.2-2 times the size of the metal mold; ② The second category: substrates with complex morphologies, which are suitable for design and manufacturing of additive manufacturing technology;

[0023] 2) Modeling and layering simulation scanning stage: For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com