An automatic stacking machine

A blank stacking machine and automatic technology, which is used in transportation and packaging, destacking of objects, stacking of objects, etc., can solve the problems of brick falling, extrusion damage, affecting brick quality, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

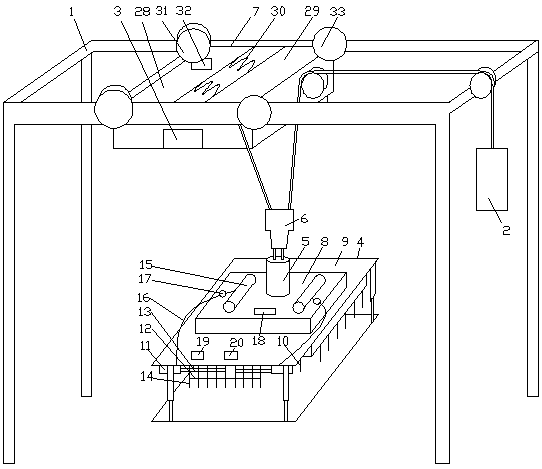

Embodiment 1

[0031] see figure 1, an automatic stacking machine, comprising a frame 1, a counterweight 2, a main frame 3, a clamping device 4 electrically connected to the main frame 3, a rotating device 5, a lifting device 6 and a walking device 7, and the running device 7 is slidably connected to the On the beam of the frame 1, the blank clamping device 4 includes a chuck 8, a telescopic frame 9 connected to the chuck 8 and multiple rows of clamps 10 connected to the inner wall of the telescopic frame 9, the chuck 8 and the rotating device 5 Fixedly connected, clamp 10 is made of cylinder 11, connecting rod 12, telescopic rod 13 and at least two splints 14 side by side, cylinder 11 is fixed on telescopic frame 9, telescopic rod 13 is connected with the piston rod of cylinder 11, splint 14 wears on On the telescopic rod 13, two adjacent splints 14 are connected by connecting rods 12 to form a linkage. The chuck 8 is connected with an air storage tank 15, and the cylinder 11 communicates w...

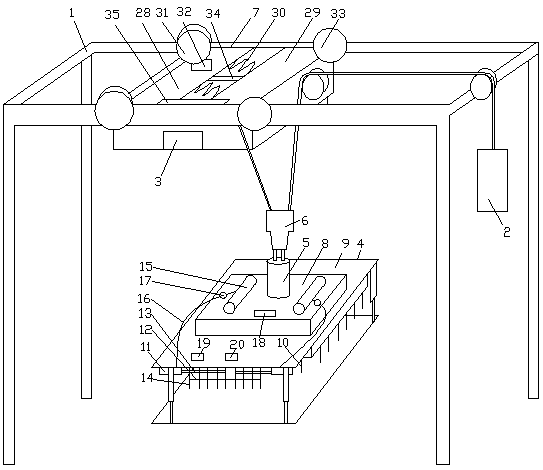

Embodiment 2

[0034] see figure 2 , an automatic stacking machine, comprising a frame 1, a counterweight 2, a main frame 3, a clamping device 4 electrically connected to the main frame 3, a rotating device 5, a lifting device 6 and a walking device 7, and the running device 7 is slidably connected to the On the beam of the frame 1, the blank clamping device 4 includes a chuck 8, a telescopic frame 9 connected to the chuck 8 and multiple rows of clamps 10 connected to the inner wall of the telescopic frame 9, the chuck 8 and the rotating device 5 Fixedly connected, clamp 10 is made of cylinder 11, connecting rod 12, telescopic rod 13 and at least two splints 14 side by side, cylinder 11 is fixed on telescopic frame 9, telescopic rod 13 is connected with the piston rod of cylinder 11, splint 14 wears on On the telescopic rod 13, two adjacent splints 14 are connected by connecting rods 12 to form a linkage. The chuck 8 is connected with an air storage tank 15, and the cylinder 11 communicates...

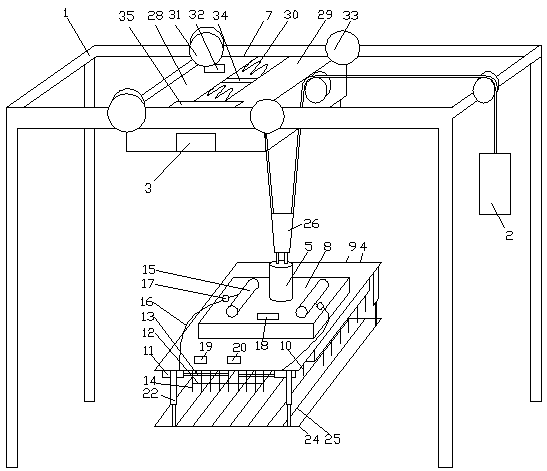

Embodiment 3

[0038] see figure 2 , an automatic stacking machine, comprising a frame 1, a counterweight 2, a main frame 3, a clamping device 4 electrically connected to the main frame 3, a rotating device 5, a lifting device 6 and a walking device 7, and the running device 7 is slidably connected to the On the beam of the frame 1, the blank clamping device 4 includes a chuck 8, a telescopic frame 9 connected to the chuck 8 and multiple rows of clamps 10 connected to the inner wall of the telescopic frame 9, the chuck 8 and the rotating device 5 Fixedly connected, clamp 10 is made of cylinder 11, connecting rod 12, telescopic rod 13 and at least two splints 14 side by side, cylinder 11 is fixed on telescopic frame 9, telescopic rod 13 is connected with the piston rod of cylinder 11, splint 14 wears on On the telescopic rod 13, two adjacent splints 14 are connected by connecting rods 12 to form a linkage. The chuck 8 is connected with an air storage tank 15, and the cylinder 11 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com