Preparation method of vinyl collagen

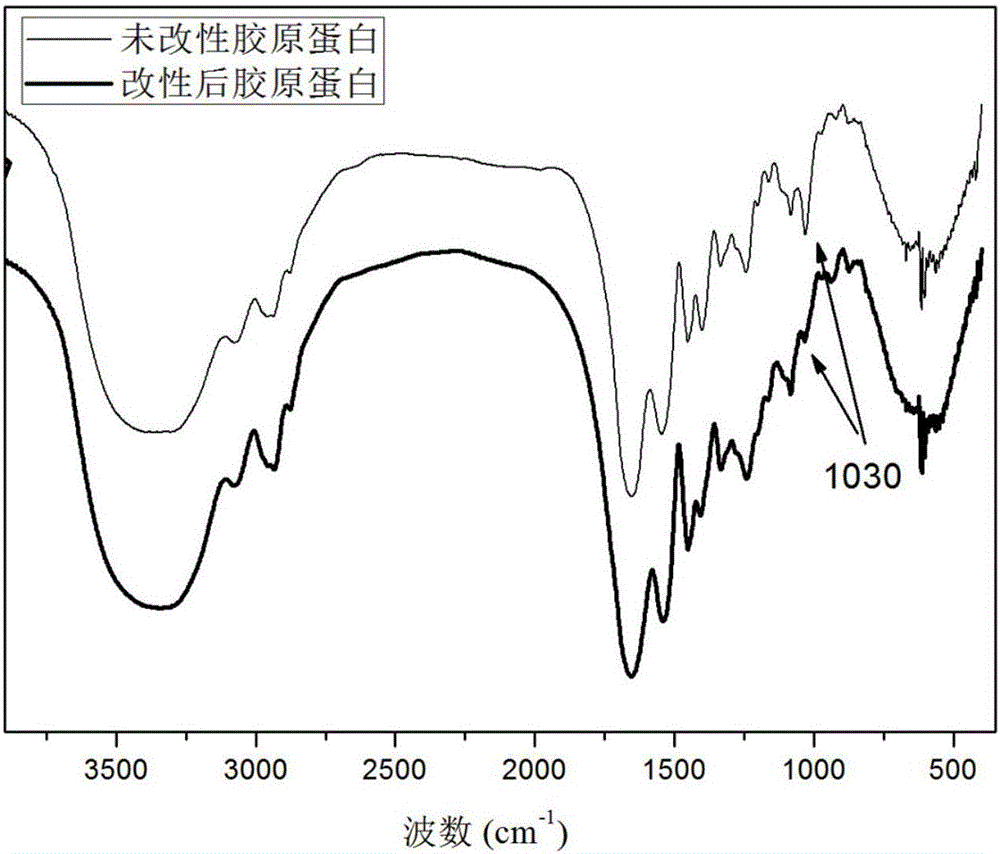

A collagen and protoprotein technology, applied in the field of vinyl collagen preparation, can solve the problems of collagen thermal stability and poor physical and mechanical properties, and achieve the effects of low equipment requirements, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

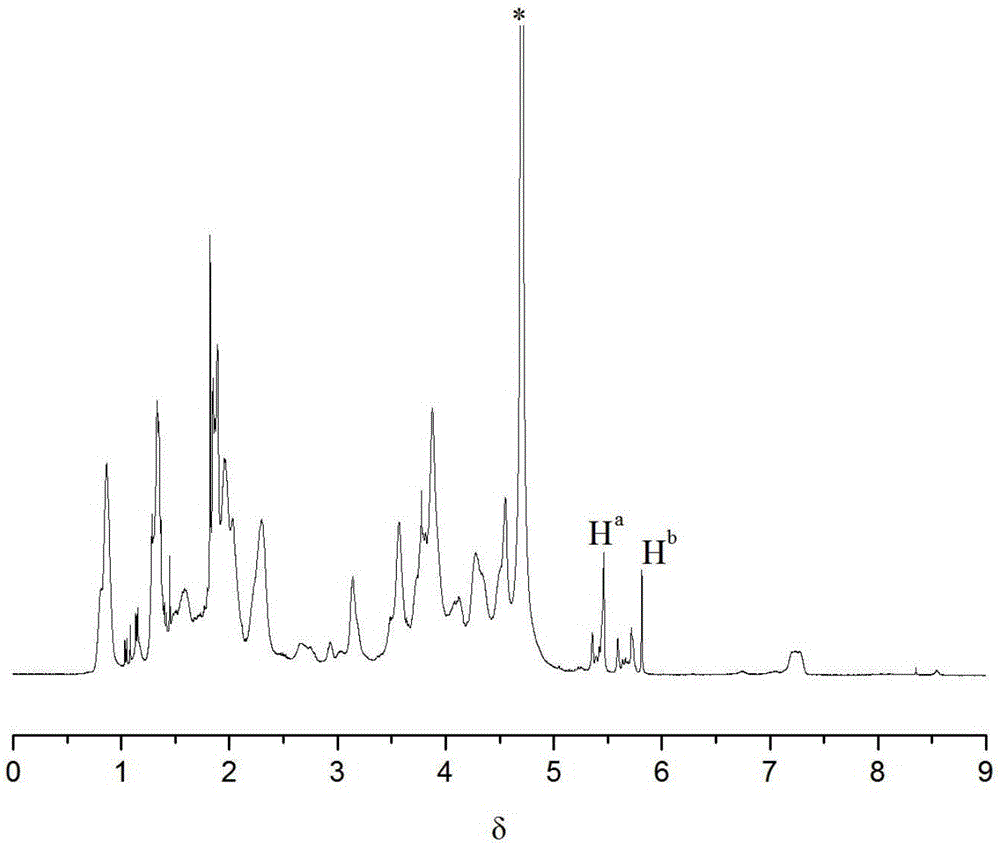

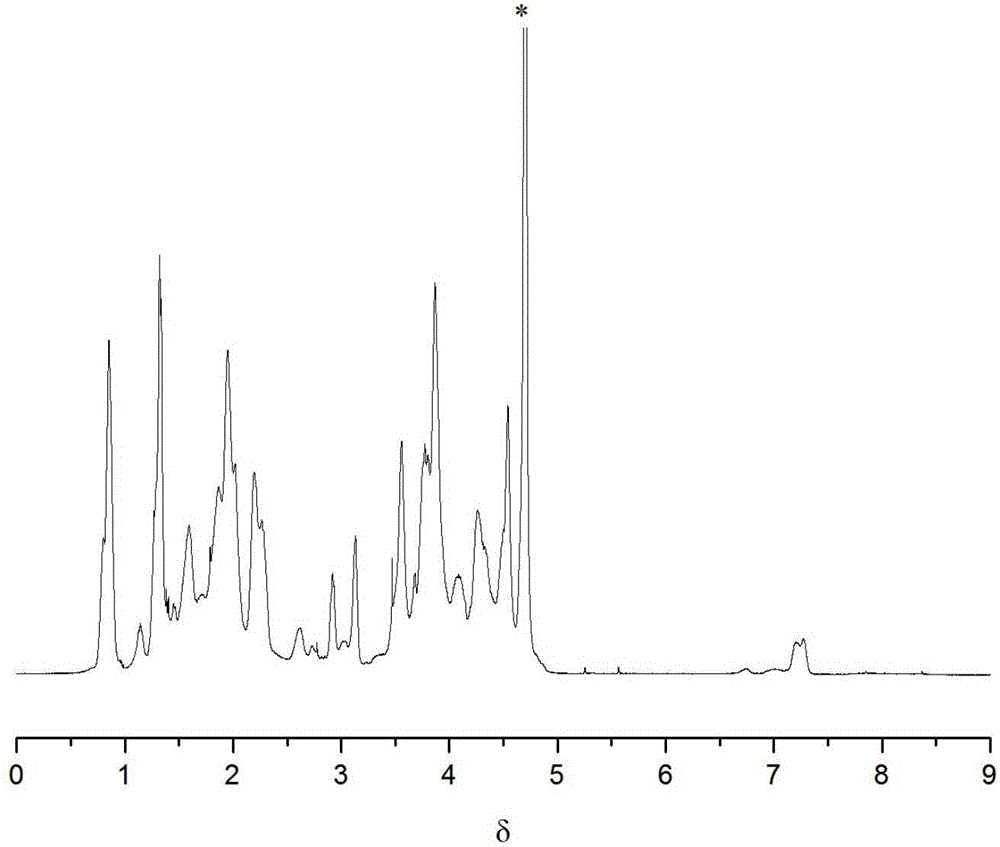

[0024] A kind of preparation method of vinyl collagen of the present invention, specifically implement according to the following steps:

[0025] Step 1: Weigh collagen (weight average molecular weight 4825, 145508 or 181266) and mix it with phosphate buffer solution (pH 7.4), stir at 70°C ± 2°C for 0.5-1 hour to fully dissolve it, and obtain Collagen solution. Wherein, the mass volume ratio of collagen to phosphate buffer solution is 1:8˜1:12 (g / mL).

[0026] Step 2, put the collagen dissolved in step 1 in a water bath environment at a temperature of 30-80° C., add methacrylic anhydride with a mass concentration of 94% at a rate of 1 mL / min, and stir for 1-6 hours to obtain Collagen solution after modification; wherein, the volume-mass ratio of methacrylic anhydride to collagen is 0.1:5-2.4:5 (mL / g).

[0027] Step 3, place the collagen solution modified in step 2 in a dialysis bag with a suitable molecular weight (500D or 3500D), use deionized water as the dialysate, and di...

Embodiment 1

[0034] Step 1, weighing 5 g of collagen with a weight average molecular weight of 181266 and mixing it with 50 mL of phosphate buffer solution (pH 7.4), stirring at 70° C. for 0.5 h to fully dissolve it.

[0035] Step 2, put the collagen solution in step 1 in a water bath environment at a temperature of 40° C., add 0.1 mL of methacrylic anhydride to it at a rate of 1 mL / min, stir and react for 2 hours, and obtain vinyl collagens with different degrees of substitution ( CMA) solution.

[0036] Step 3, put the CMA solution in step 2 into a suitable dialysis bag with a molecular weight of 3500D, use deionized water as the dialysate, dialyze at 40°C for 24 hours, and place the dialyzed collagen solution in a freeze dryer , pre-frozen at -20°C, and then freeze-dried for later use.

Embodiment 2~ Embodiment 9

[0038] Referring to Example 1, the difference from Example 1 is that in step 2, the amount of methacrylic anhydride added is 0.3mL, 0.6mL, 0.9mL, 1.2mL, 1.5mL, 1.8mL, 2.1mL and 2.4mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com