Knitted fabric sized edge pre-drying device of tentering setting machine

A tenter setting and pre-drying technology, which is used in textiles and papermaking, textile processing machine accessories, textile material processing, etc. , to achieve the effect of reducing energy consumption, reducing enterprise costs, and preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

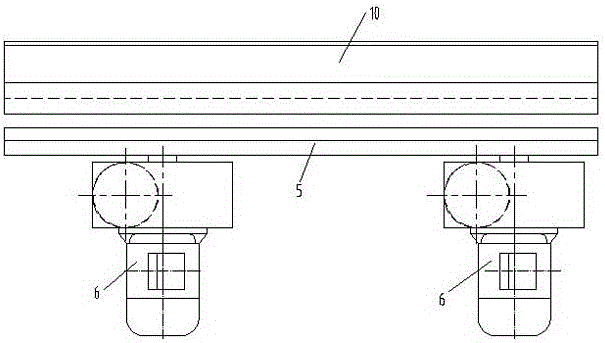

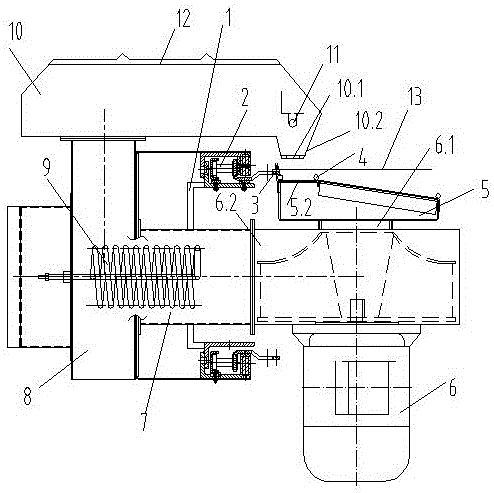

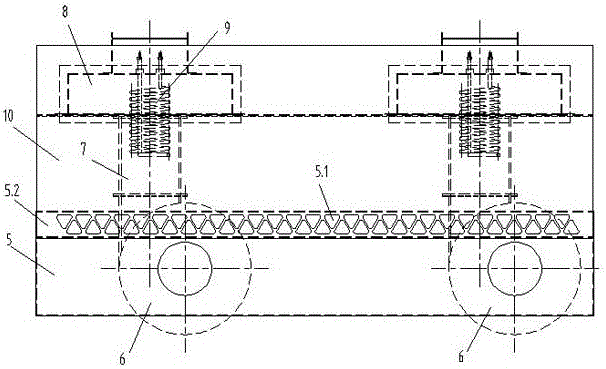

[0013] Embodiment 1: A pulp edge pre-drying device for knitted fabrics of a stenter setting machine, comprising a setting machine beam 1, a guide rail 2 arranged on the beam 1, a cloth clip needle plate 3 connected to the guide rail 2, and a clip needle plate 3 arranged on the cloth clip needle The cloth guide post 4 below the plate 3, the cloth edge 13 is clamped between the cloth guide post 4 and the cloth clip needle plate 3, a bracket 5 is arranged under the cloth guide post 4, and the bracket 5 is a sealed casing with a trapezoidal cross section. The upper surface 5.2 of the housing of the bracket 5 is evenly provided with triangular air return holes 5.1, and two fans 6 are arranged below the bracket 5, and the air return port 6.1 of the fan 6 is connected to the lower end surface of the housing of the bracket 5, and the air outlet 6.2 of the fan 6 passes through a The No. 1 air duct 7 is connected to the vertical No. 2 air duct 8, the No. 1 air duct 7 or the No. 2 air duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com