High-reliability exhaust and flow-limiting structure of automobile engine cooling system

An automobile engine and cooling system technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve problems such as unfavorable engine warm-up, automobile coolant boiling, etc., to achieve accurate buoyancy, reduce flow loss, and reliability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, but do not limit protection scope and application scope of the present invention:

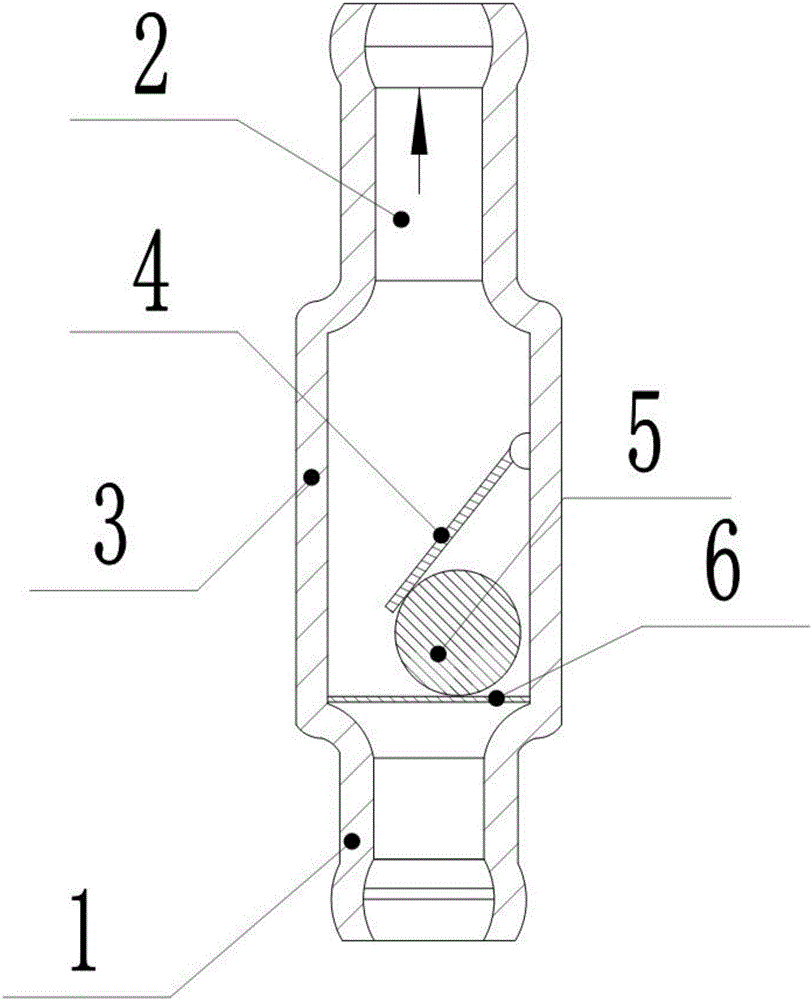

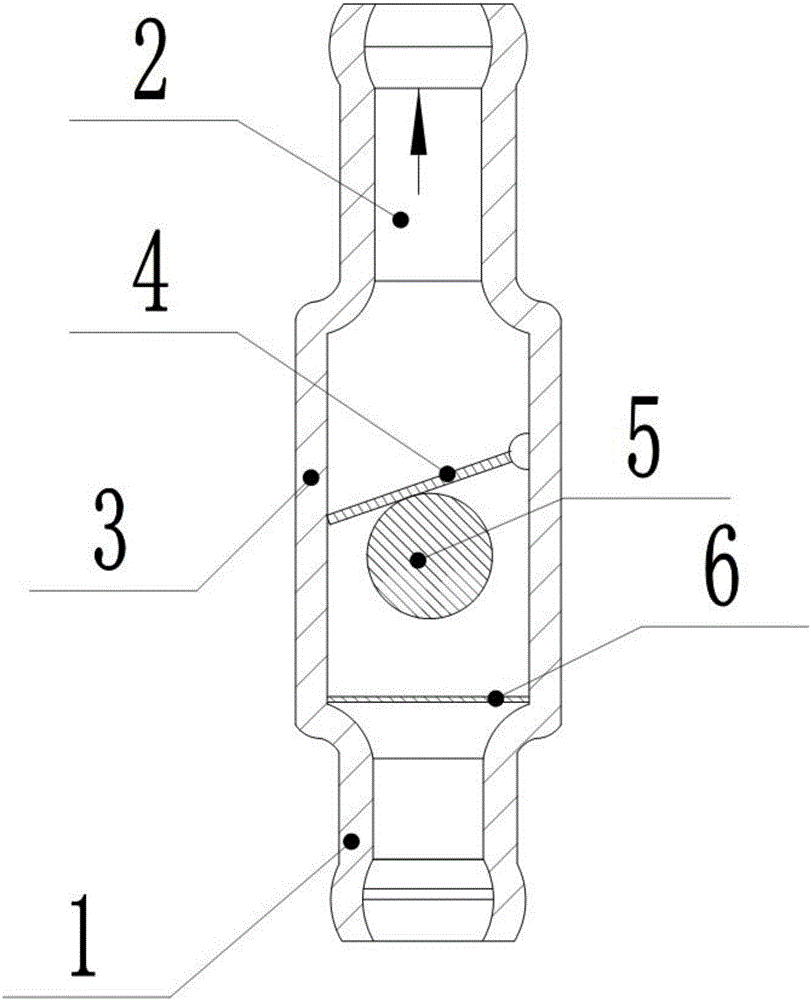

[0013] like figure 1 As shown in the figure, a high-reliability automobile engine cooling system exhaust flow limiting structure includes an exhaust pipe 1 connected to the engine exhaust hole and an intake pipe 2 connected to the expansion tank. The exhaust pipe 1 and the intake pipe 2 pass through the casing 3 connection, preferably, the two ends of the casing 3 are welded to the exhaust pipe 1 and the intake pipe 2 respectively. A grid plate 6 is arranged at the bottom of the casing 3, and a movable balloon 5 is placed on the grid plate 6, and an ellipse with one end hinged to the inner wall of the casing 3 and whose minor axis length is greater than the inner diameter of the casing 3 is provided in the casing 3. shaped baffle plate 4, the non-hinged end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com