Plant salt containing sea salt and bitter gourd powder and method for preparing the plant salt by using mineralizing and filtering technology

A technology of plant salt and bitter gourd powder, which is applied in the field of development and utilization of plant salt, can solve problems such as insufficient functionality, achieve good therapeutic effect, low content of heavy metal ions, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

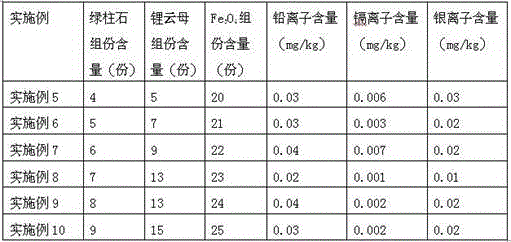

Examples

Embodiment 1

[0032] Example 1 : Preparation of Vegetable Salt Containing Sea Salt and Bitter Melon Powder

[0033] step 1 , Refined brine preparation

[0034] (1) Brine precipitation

[0035] Collect coastal brine, pass it into the sedimentation tank, and settle for 1 hour. After testing, the lead ion content is 35mg / L, the cadmium ion content is 30mg / L, and the silver ion content is 25mg / L.

[0036] (2) filter

[0037] Pass the precipitated brine into the brine mineralization filter, and circulate and filter for 3 times, fill the brine mineralization filter with a brine mineralization filter agent, and obtain refined saturated brine after the filtration is completed.

[0038] The preparation method of brine mineralization filter agent is:

[0039] The brine mineralization filter is composed of the following components by weight percentage: chlorella: 36 parts, beryl: 4 parts, lepidolite: 5 parts, medical stone: 6 parts, Fe 3 o 4 : 21 servings.

[0040] Preparation of ingre...

Embodiment 2

[0064] Example 2 : Preparation of Vegetable Salt Containing Sea Salt and Bitter Melon Powder

[0065] step 1 , Refined brine preparation

[0066] (1) Brine precipitation

[0067] Collect coastal brine, pass it into the sedimentation tank, and settle for 2 hours. After testing, the content of lead ions is 30mg / L, the content of cadmium ions is 35mg / L, and the content of silver ions is 25mg / L.

[0068] (2) filter

[0069] Pass the precipitated brine into the brine mineralization filter, and circulate and filter for 4 times. The brine mineralization filter is filled with a brine mineralization filter agent. After the filtration, refined saturated brine is obtained.

[0070] The preparation method of brine mineralization filter agent is:

[0071] The brine mineralization filter is composed of the following components by weight percentage: 48 parts of chlorella, 6 parts of beryl, 10 parts of lepidolite, 16 parts of medical stone, Fe 3 o 4 : 22 servings.

[0072] Pre...

Embodiment 3

[0096] Example 3 : Preparation of Vegetable Salt Containing Sea Salt and Bitter Melon Powder

[0097] step 1 , Preparation of refined brine

[0098] (1) Brine precipitation

[0099] Collect coastal brine, pass it into the sedimentation tank, and settle for 3 hours. After testing, the content of lead ions is 25mg / L, the content of cadmium ions is 35mg / L, and the content of silver ions is 20mg / L.

[0100] (2) filter

[0101] The precipitated brine is passed into a brine mineralization filter, and circulated and filtered for 3 times, and the brine mineralization filter is filled with a brine mineralization filter agent. After the filtration is completed, refined saturated brine is obtained.

[0102] The preparation method of brine mineralization filter agent is:

[0103] The brine mineralization filter is composed of the following components by weight percentage: 55 parts of chlorella, 7 parts of beryl, 13 parts of lepidolite, 8 parts of medical stone, Fe 3 o 4 : ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com