Pressure control system of bottle washing machine, and control method and application thereof

A technology of pressure control and bottle washing machine, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of uncontrollable system temperature, reduced service life of filter elements, and influence of bottle washing pressure on cleaning effect, etc. Achieve parameter adjustment, reduce loss, and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

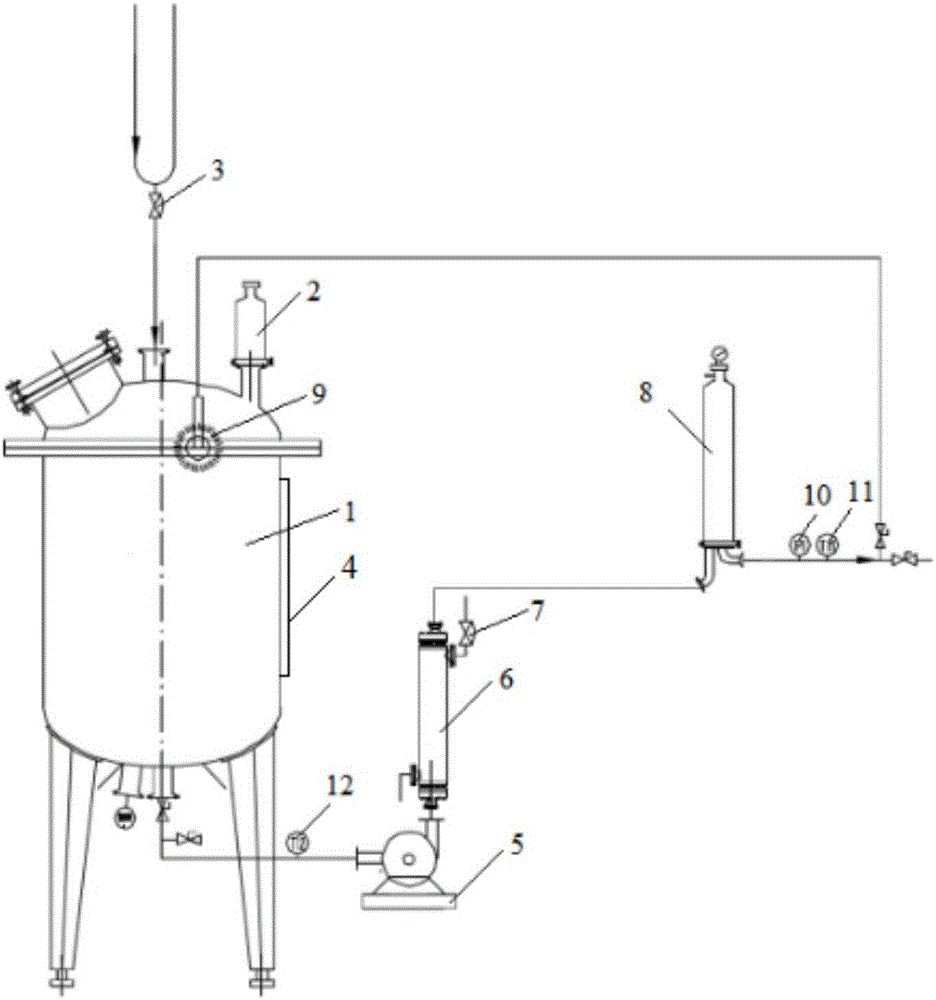

[0019] The pressure control system of the bottle washing machine, including the buffer tank 1, the respirator 2, the water inlet pneumatic valve 3, the level gauge 4, the water supply variable frequency pump 5, the bottle washing machine filter 8, and the pressure sensor 10 are connected by pipelines, and the pipeline outlet is connected to the washing machine. The bottle machine water supply point connection.

[0020] The water inlet pneumatic valve 3 is installed on the pipeline at the inlet of the buffer tank 1. The top of the buffer tank 1 is provided with a respirator 2. Since in actual operation, the buffer tank 1 contains cold water or hot water, during the heating or cooling process It is necessary to keep the air in the buffer tank 1 smooth to avoid positive or negative pressure. Therefore, adding a respirator 2 can ensure that the air in the buffer tank 1 reaches a certain degree of cleanliness, so that the entire large and small circulating air is not polluted or cross-...

Embodiment 2

[0022] Bottle washing machine pressure control system, including buffer tank 1, respirator 2, water inlet pneumatic valve 3, liquid level gauge 4, water supply variable frequency pump 5, double tube plate heat exchanger 6, steam pneumatic valve 7, temperature sensor I11, temperature Sensor II 12, bottle washer filter 8 and pressure sensor 10. Water inlet pneumatic valve 3 is installed on the pipeline at the inlet of buffer tank 1. The top of buffer tank 1 is provided with breathing apparatus 2 and the buffer tank 1 is provided with a liquid level Meter 4, the buffer tank 1 is connected to the water supply variable frequency pump 5. The downstream of the pipeline where the water supply variable frequency pump 5 is located is equipped with a double tube plate heat exchanger 6 and a bottle washing machine filter 8. The temperature sensor II 12 is located at the double tube plate heat exchanger 6 Upstream, the temperature sensor I11 is located downstream of the double tube sheet hea...

Embodiment 3

[0024] The pressure control system of the bottle washing machine includes a buffer tank 1, a respirator 2, a water inlet pneumatic valve 3 located on the upper part of the buffer tank 1, a level gauge 4 on the buffer tank 1, a water supply variable frequency pump 5, and a double tube plate heat exchanger 6. Steam pneumatic valve 7, bottle washing machine filter 8, cleaning spray ball 9, pressure sensor 10, temperature sensor I11 and temperature sensor II12. The bottom outlet of the buffer tank 1 is connected to one end of the water supply variable frequency pump 5. The water supply The other end of the variable frequency pump 5 is connected to the double tube plate heat exchanger 6, and a temperature sensor II 12 is also provided at the front end of the water supply variable frequency pump 5, and the double tube plate heat exchanger 6 is provided with a steam pneumatic valve 7, and the double tube plate heat exchanger The heater 6 is connected to the filter 8 of the bottle washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com