Method for accurate numerically-controlled drilling on large-curvature arc surface

A large-curvature arc surface and precise technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems of low processing efficiency, deviation of drilling direction, slow feed, etc. Achieve the effects of improved processing efficiency, stable clamping and obvious efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation process of the solution of the present invention will be further described below in conjunction with the drawings.

[0024] A method for precise numerical control drilling on a large curvature arc surface, the steps are as follows:

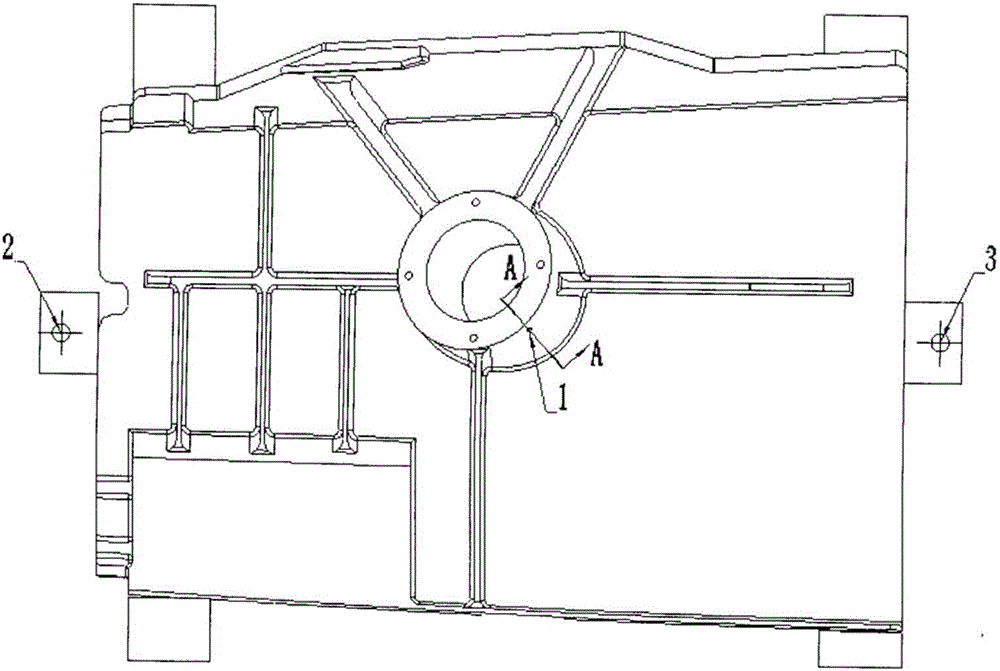

[0025] (1) such as figure 1 As shown, according to the hole position of the hole 1 on the part, the direction of the hole axis, and the part positioning boss holes 2, 3, select the CNC machine tool that meets the processing requirements, and the accuracy of the CNC machine tool is required to be within the required range of hole diameter and hole position accuracy and good performance , Can choose horizontal CNC machining center;

[0026] (2) Accurate drilling of arc surface of titanium alloy parts with large curvature

[0027] (2.1) Such as figure 1 As shown, the parts are placed on the machine tool table to ensure accurate positioning, stable clamping, and ensure that there is no interference and collision during processing;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com