Movable machine tool

A technology of machine tools and planers, applied in the field of pipeline processing equipment, to achieve the effects of ensuring processing safety, reducing equipment costs, and saving procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

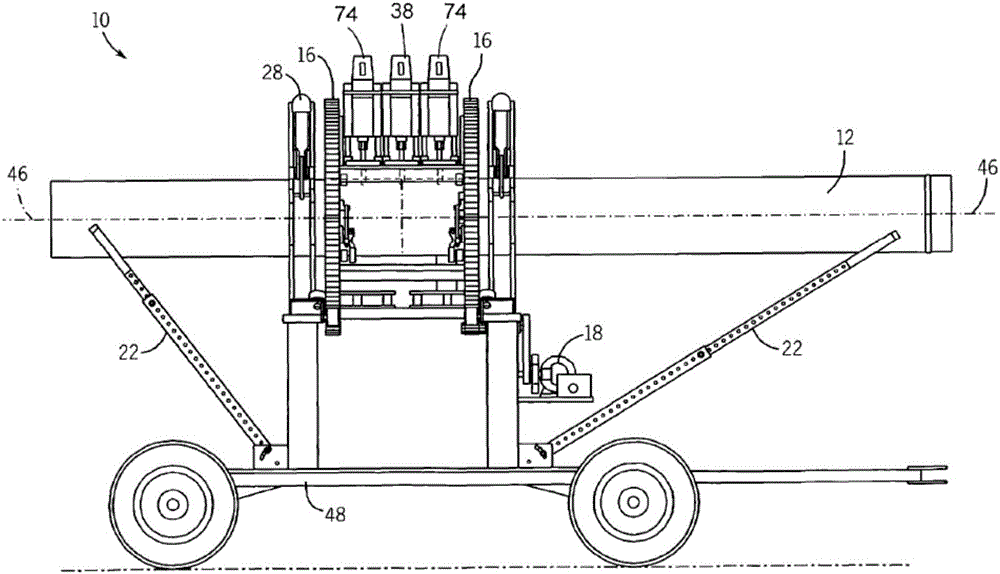

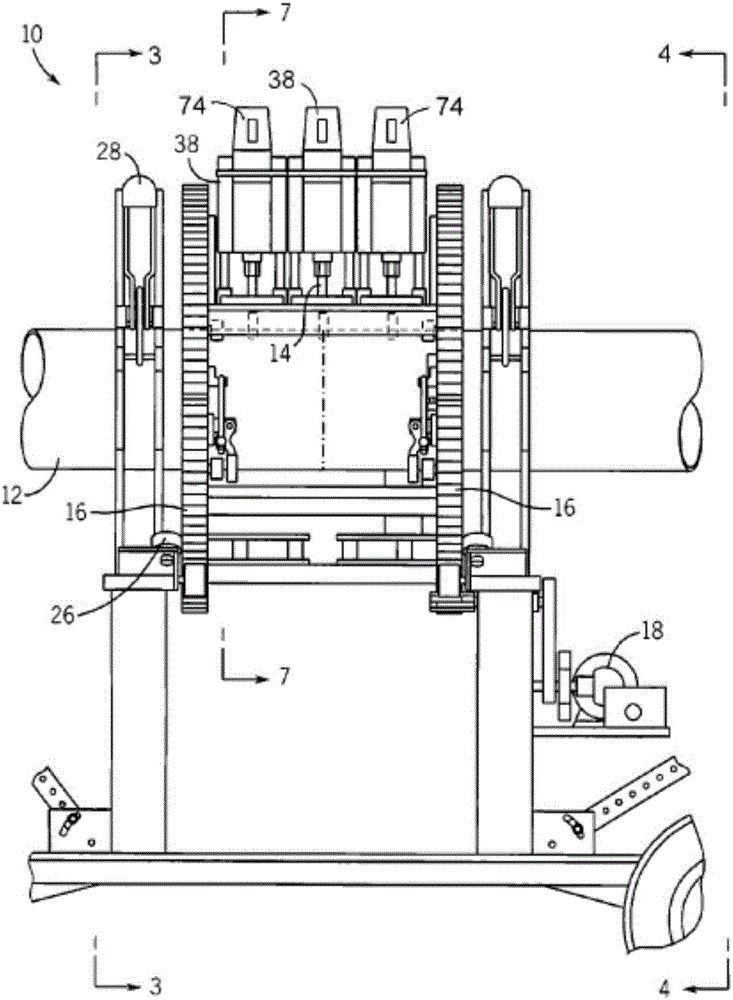

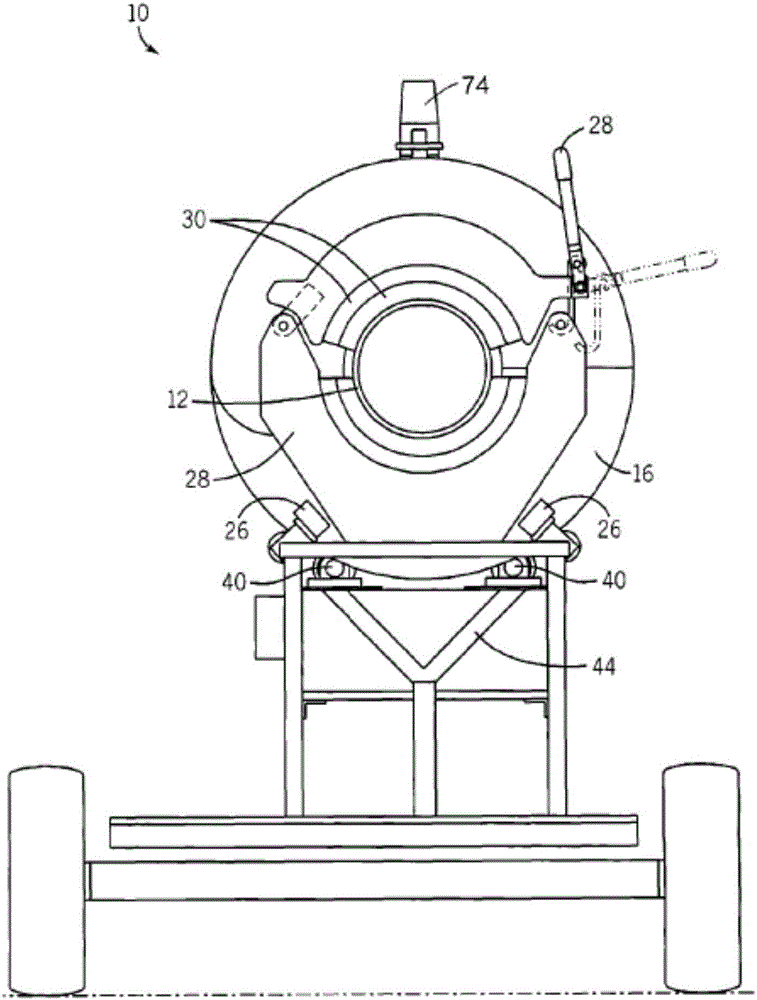

[0034] refer to Figure 1-13a A kind of mobile machine tool 10 shown is used for simultaneously cutting, chamfering, slotting to pipeline, described mobile machine tool comprises a support 48, at least one pipe clamp 28 is fixed on the support 48, and described pipe clamp 28 locates a main shaft 46, the separating carriage 16 is rotatably fixed on the bracket 48 and connected with the pipe clamp 28, a router 38 is fixed on the separating carriage 16, and the router 38 includes a chamfering cutting unit 14, a The router 74 for digging is fixed on the bracket 48, and a driving motor 18 is used to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com