Paper pallet in triangular girder inserting connection

A triangular and tray technology, which is applied in the field of triangular beam plug-in full paper trays, can solve the problems of troublesome recycling and reuse of paper trays, and achieve the effect of good popularization and application value, reasonable design, and improved bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

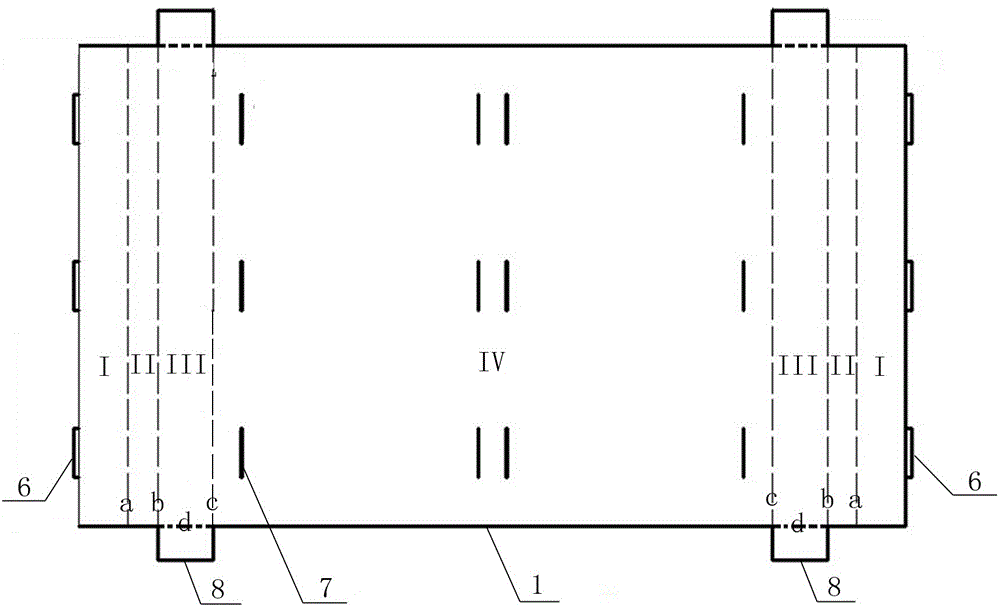

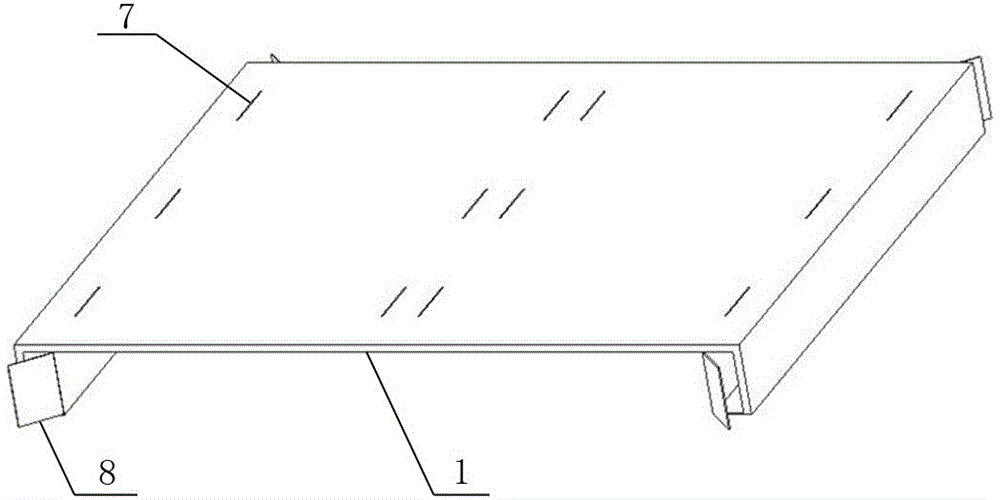

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

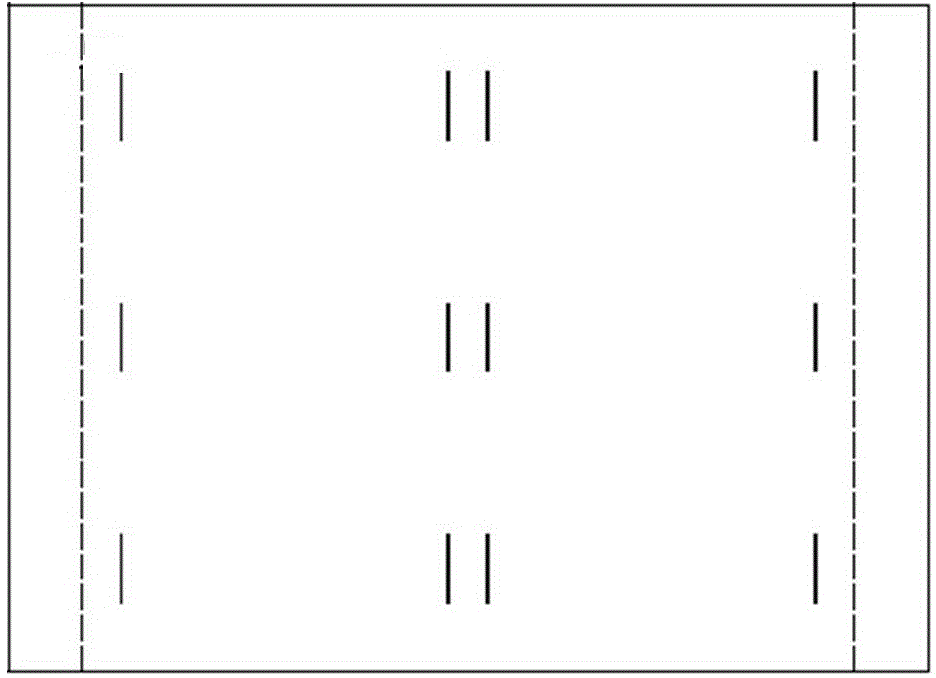

[0026] A triangular beam plug-in full-paper pallet is composed of a main outer box structure and an internal support structure, and is formed by folding planks and inserting internal support components. Among them, the main outer box structural components are composed of corrugated cardboard-paper-shaped rectangular bearing panels and the outer surface of the longitudinal beams. The longitudinal beam support structure is composed of a series of vertically arranged rectangular panels with protruding plug-in structures. The details are as follows: All parts are made of corrugated cardboard, and the thickness of corrugated cardboard is 2mm.

[0027] Pallet decking outer box design

[0028] Such as figure 1 As shown, it includes pallet decking 1, and the middle of the pallet decking 1 is the fourth plane , the two sides of the pallet decking 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com