Method for achieving precise centring by means of simultaneous movement of multiple chain plate conveyors

A chain conveyor and synchronous movement technology, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of high equipment space requirements and poor flexibility, and achieve high positioning accuracy, cost saving, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

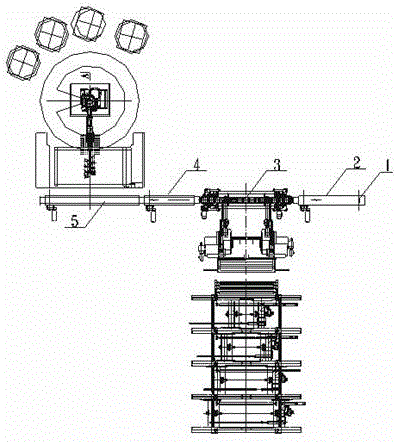

[0020] The method of moving multiple chain conveyors at the same time for accurate centering is used for the adjustment of fully automatic double-station packaging machines or multiple synchronous chain conveyors. Include the following steps:

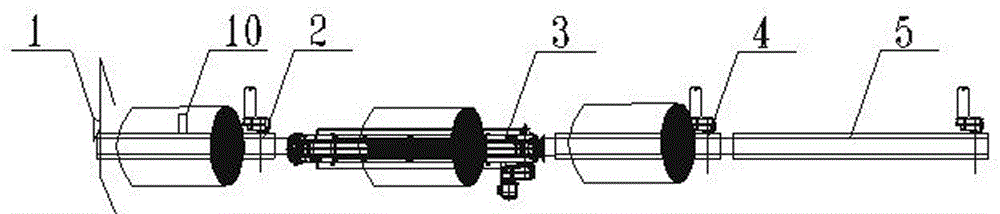

[0021] a. The scanner 1 is installed above the chain plate machine 3 at the folding station, reads the paper roll data by scanning the barcode information of the paper roll and transmits it to the chain plate conveyor to provide the paper roll data information of the paper roll, and calculates through the paper roll barcode width information The number of pulses from the paper roll to the encoder value.

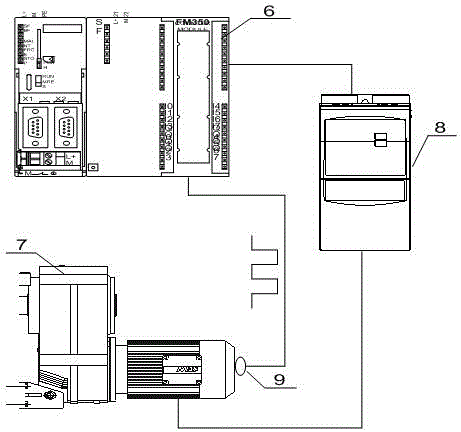

[0022] b. The encoder 9 is installed at the tail of the motor of the chain plate machine 2 at the folding station. The operation of the motor 7 drives the operation of the encoder 9 to directly read the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com