Anti-fungal aviation refuse bag and a preparation method thereof

A technology of anti-mold and garbage bags, which is applied in the field of anti-mold aviation garbage bags and its preparation, can solve the problems of low mechanical strength of paper garbage bags and the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The invention provides a method for preparing an anti-mold aviation garbage bag, wherein the preparation method comprises: mixing low-density polyethylene resin, ethyl acetate, chemical fiber, sodium silicate and anti-mold agent OBPA, melting, extruding granulation to obtain the masterbatch M; the masterbatch M is subjected to a blow molding process to obtain an anti-mold aviation garbage bag; wherein, relative to 100 parts by weight of low-density polyethylene resin, the amount of ethyl acetate is 20-40 In parts by weight, the chemical fiber is used in an amount of 2-12 parts by weight, the sodium silicate is used in an amount of 5-10 parts by weight, and the antifungal agent OBPA is used in an amount of 1-5 parts by weight.

[0013] In order to make the prepared garbage bag have more excellent mechanical strength and the ability to inhibit mold, in a preferred embodiment of the present invention, with respect to the low density polyethylene resin of 100 parts by weight...

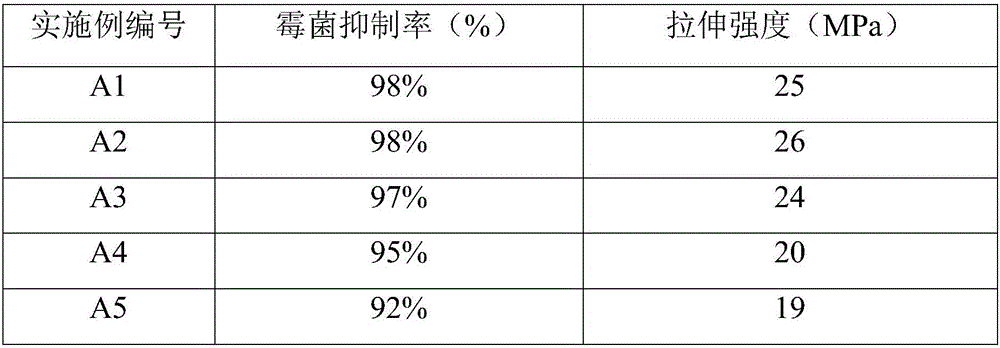

Embodiment 1

[0020] 100g of low-density polyethylene resin, 25g of ethyl acetate, 5g of polyamide fiber, 6g of sodium silicate and 2g of antifungal agent OBPA are mixed and then melted (at a temperature of 200° C.), extruded and granulated to obtain masterbatch M; The material M was blow-molded to obtain the anti-mold aviation garbage bag A1.

Embodiment 2

[0022] 100g low-density polyethylene resin, 35g ethyl acetate, 8g polyacrylonitrile fiber, 8g sodium silicate and 4g antifungal agent OBPA are mixed and then melted (the temperature is 220° C.), extruded and granulated to obtain masterbatch M; The masterbatch M is subjected to a blow molding process to obtain an anti-mold aviation garbage bag A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com