Manufacturing method for flat Sc-containing high-Mg aluminum alloy cast ingot

A manufacturing method and aluminum alloy technology, which are applied in the manufacturing field of high-Mg aluminum alloy flat ingots, can solve the problems of low strength and easy softening strength, and achieve the advantages of reducing hydrogen content and alkali metals, improving mechanical properties, and improving alloy strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

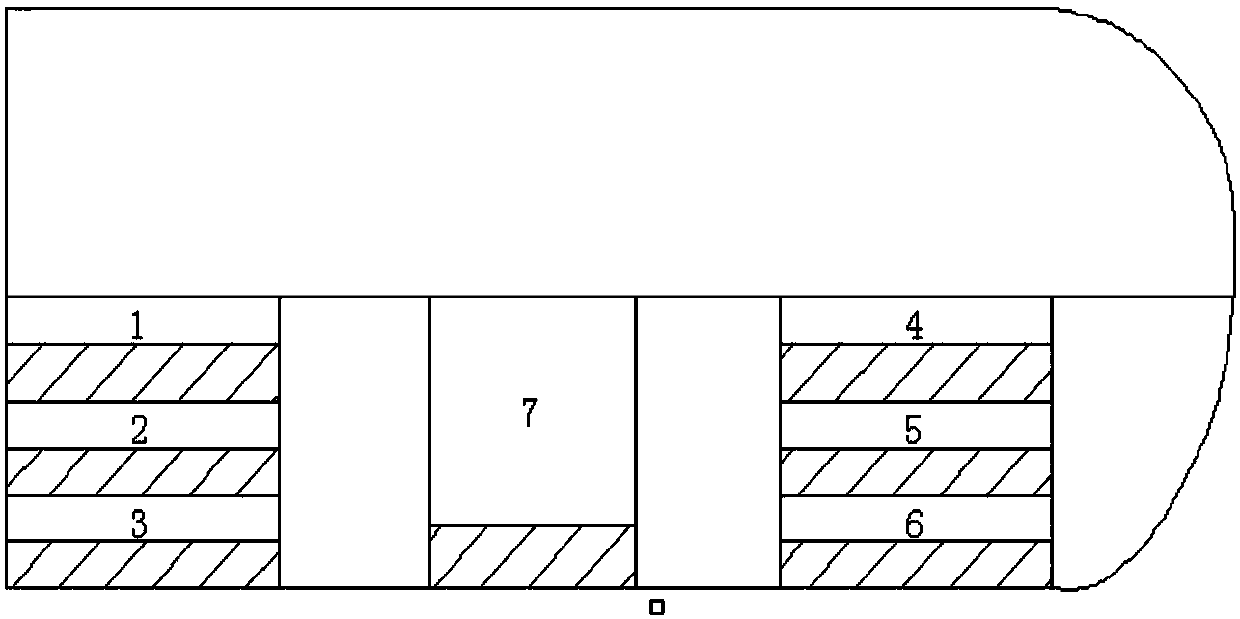

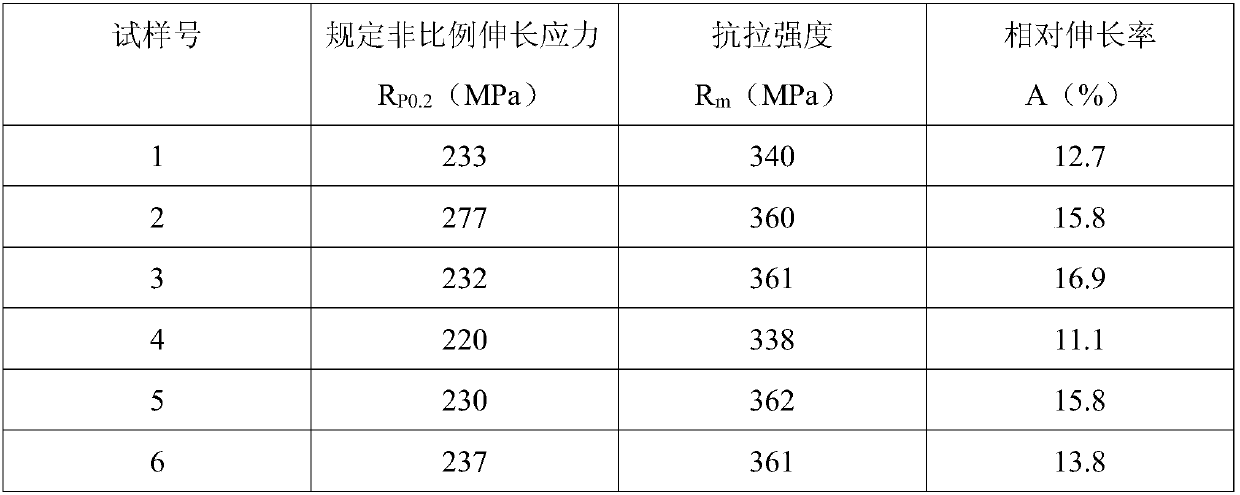

[0023] Embodiment 1: A method for manufacturing a Sc-containing high Mg aluminum alloy slab ingot according to the present embodiment is carried out according to the following steps:

[0024] 1. Weigh the smelting raw materials: ①According to the mass percentage of each element: Mn is 0.15%-0.4%, Mg is 5.8%-6.4%, Sc is 0.2%-0.3%, Zr is 0.1%-0.18%, and Ti is 0.02% %~0.04% and the balance of Al weigh aluminum ingots, Al-Zr master alloys, Al-Mn master alloys, Al-Sc master alloys, magnesium ingots and Al-Ti master alloys; ②According to the quality of Al-Be master alloys The ratio to the total mass of the smelting raw materials weighed is (1~3):9×10 3 Weigh the Al-Be master alloy;

[0025] 2. Melting: According to the order of aluminum ingots, Al-Zr master alloys and Al-Mn master alloys, the raw materials are put into the resistance reverberatory furnace for melting. Under the condition of constant temperature of ℃~810℃, first add Al-Sc master alloy, then add magnesium ingot, Al-...

specific Embodiment approach 2

[0040] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, according to the mass percentage of each element: Mn is 0.3%, Mg is 6.2%, Sc is 0.22%~0.26%, Zr is 0.14%, Ti is 0.03% and the balance of Al is weighed as aluminum ingot, Al-Zr master alloy, Al-Mn master alloy, Al-Sc master alloy, magnesium ingot and Al-Ti master alloy. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, according to the mass percentage of each element: Mn is 0.3%, Mg is 6.25%, Sc is 0.25%, Zr is 0.14%, Ti Weigh aluminum ingots, Al-Zr master alloys, Al-Mn master alloys, Al-Sc master alloys, magnesium ingots and Al-Ti master alloys with 0.02% and the rest of Al. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com