Special crawler chassis for raise boring machine

The technology of a crawler chassis and a patio drilling rig is applied in the field of mining machinery, which can solve the problems of increased driving resistance and steering resistance, excessive wheel ruts, smooth ground running and high requirements on firmness, and achieves the effect of ensuring stability and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

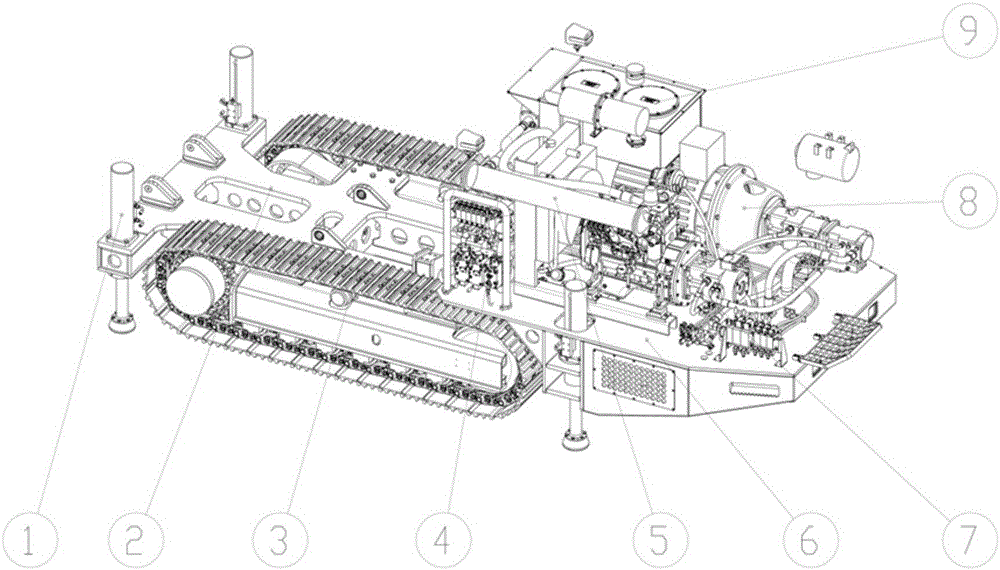

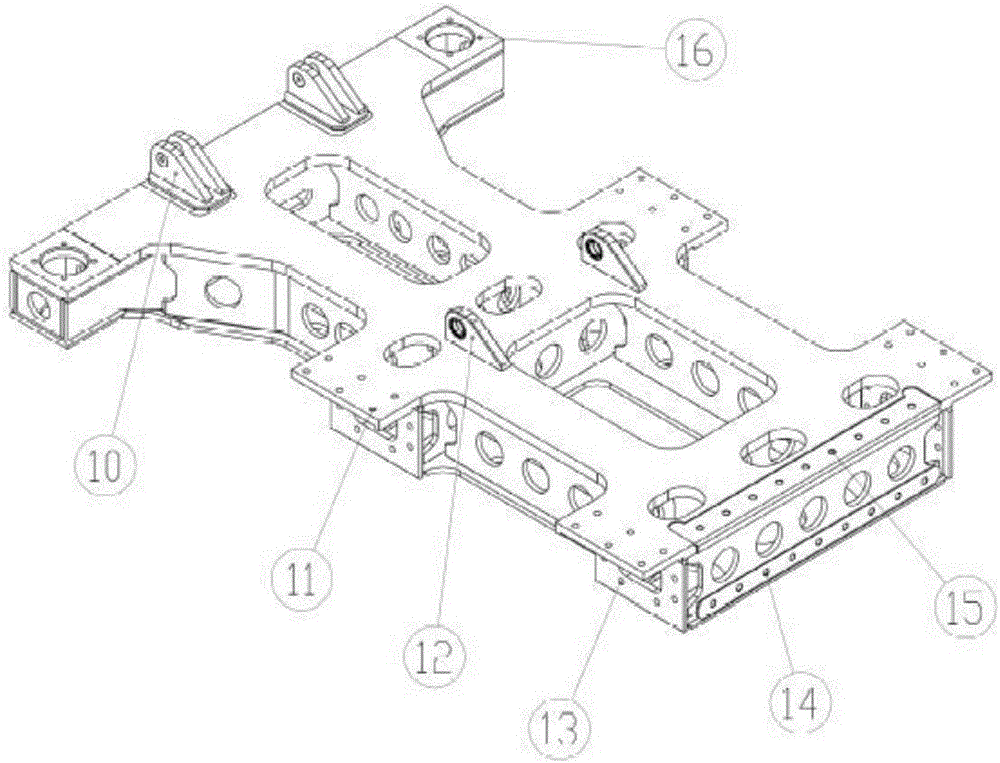

[0023] like figure 1 , 2 As shown, a crawler chassis dedicated to a raise drilling rig provided by the present invention includes a power unit assembly, a crawler belt assembly 3, a chassis frame 2 and a leg assembly 1, the power unit assembly includes a power unit chassis 6, and the The crawler belt assembly 3 is connected with the chassis frame 2, the chassis frame 2 is connected with the power unit chassis 6, the outrigger assembly 1 includes four outriggers, and two outriggers are installed on the In the supporting leg oil cylinder installation hole 16 of chassis frame 2, the other two described supporting legs are installed on the described power unit underframe 6, and the two described supporting legs installed on the described chassis frame 2 can be adjusted separately, installed The other two legs on the power unit chassis 6 are adjusted synchronously, and the bottoms of the four legs are supported on the ground.

[0024] The outrigger assembly 1 of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com