A Method for Fatigue Crack Growth Rate Estimation and Life Prediction

A technology for fatigue crack growth and life prediction, applied in calculation, special data processing applications, instruments, etc., can solve problems such as complex models or methods, and achieve the effects of easy understanding and acceptance, reasonable and credible results, and convenient calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

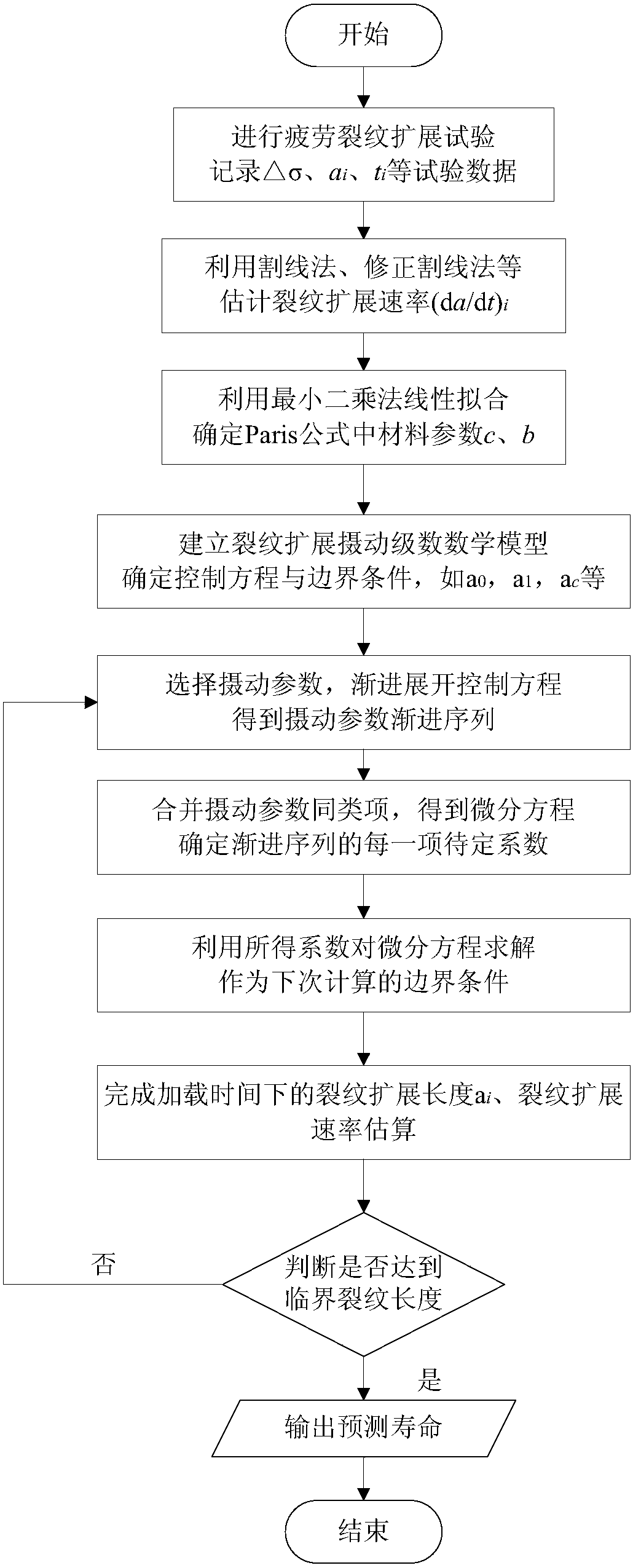

Method used

Image

Examples

Embodiment

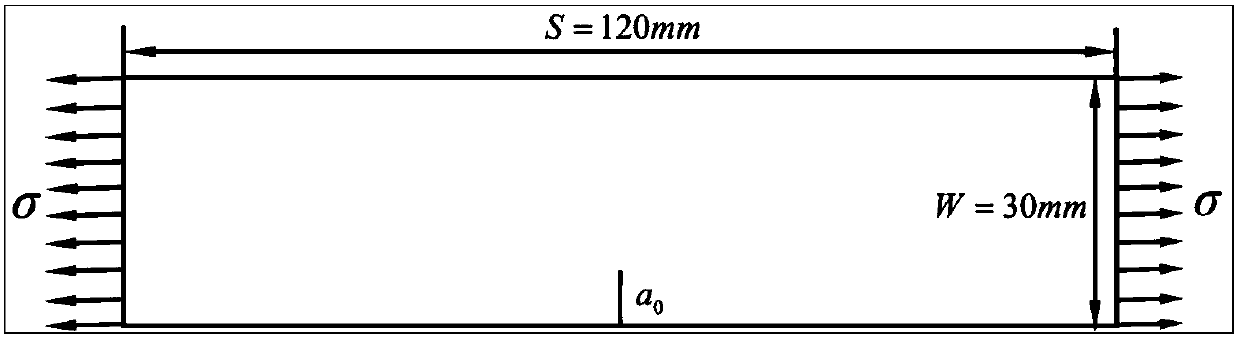

[0111] In order to understand more fully the characteristics of the invention and its applicability to engineering practice, the present invention aims at such as Figure 2-4 The fatigue crack growth rate estimation and life prediction of the 2024-T3 aluminum alloy rectangular plate with unilateral cracks under uniform load are performed. The length of the aluminum alloy rectangular plate is S=120mm, and W=30mm. Breaking strength The shape factor F is 1.07, and the constant parameters C and m of the metal material are 3.868 and 0.377e-10, respectively. Nominal value of initial crack length a 0 is 5mm, the initial disturbance comes from the resolution of the measurement device.

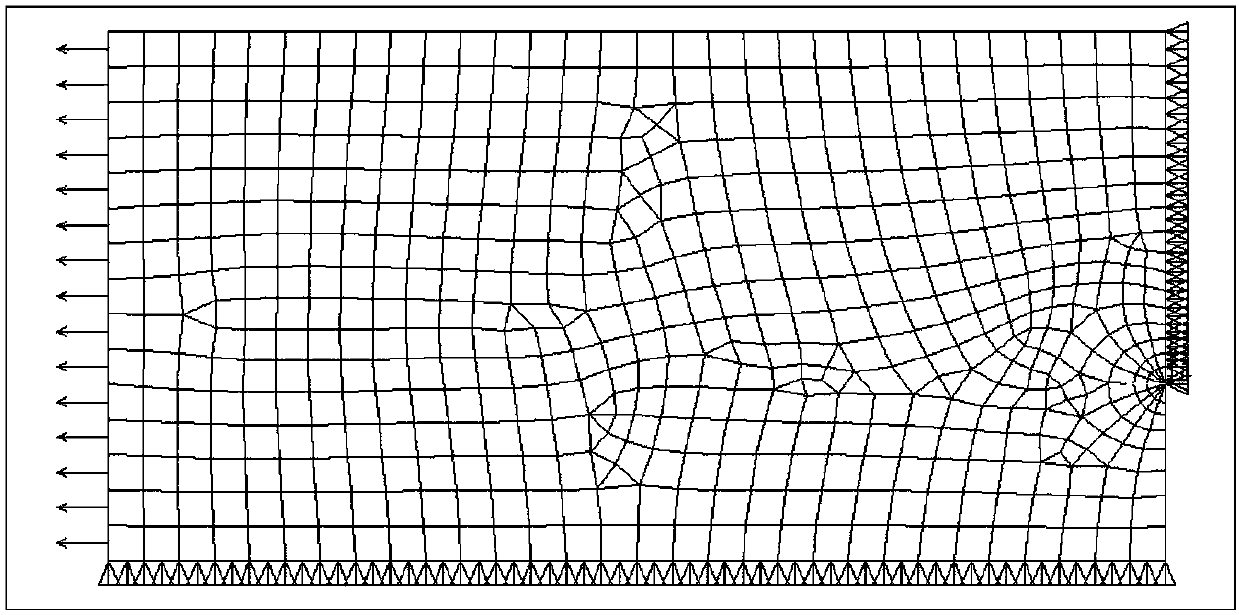

[0112] The time-crack length (t-a) curve of fatigue crack growth can be obtained by using the Paris formula without considering the initial disturbance and the stress intensity factor obtained by the large-scale finite element general-purpose software ANSYS; among them, the large-scale finite eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com