Method and system for establishing product process quality prediction model based on site data

A technology for field data and quality prediction, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low accuracy and no data analysis, and achieve the effect of avoiding singleness and preventing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail below in conjunction with accompanying drawing:

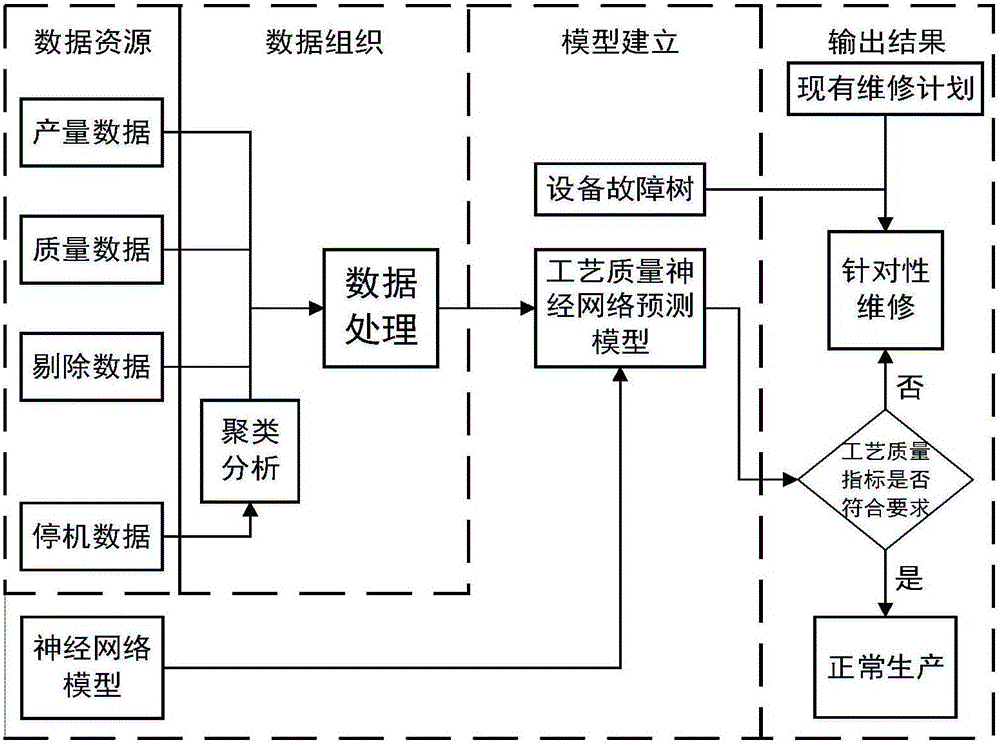

[0048] Such as figure 1 As shown, the establishment method of the product process quality prediction model based on field data includes the following steps:

[0049] Step 1. Organize data of various on-site equipment through data analysis software; Step 2. Use neural network method to predict product quality; Step 3. Formulate management strategies based on the prediction results combined with equipment fault trees.

[0050] The sorting of all kinds of on-site equipment data includes the following sub-steps: Step 11, use data analysis software to read the cigarette equipment on-site data stored in the database; Sort all kinds of data in chronological order; step 14, sort out all kinds of data in units of 15 minutes, the least common multiple of each other's collection cycle, and the data of equipment output, elimination, and shutdown are among the maximum and minimum values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com