Construction method for fabricated type corrugated steel inclined web combined beam

A technology of corrugated steel and oblique webs, which is applied in the construction field of assembled corrugated steel oblique web composite beams, can solve the problems of limited headroom, easy instability of erection, and many wet joints, so as to reduce the consumption and facilitate Transport and erection, good overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The construction method of the assembled corrugated steel oblique web composite girder of the present invention comprises the following steps:

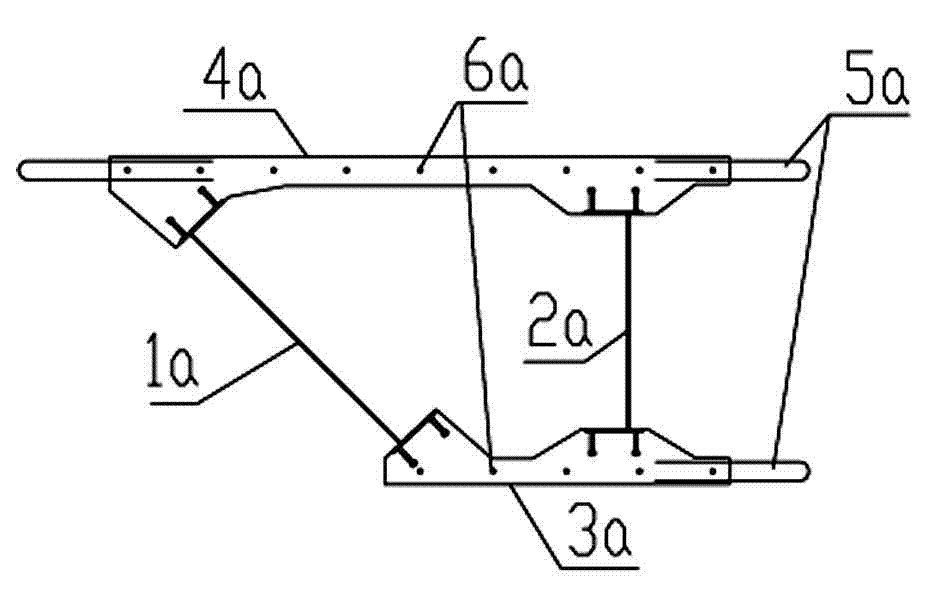

[0026] The first step is to prefabricate two pieces of corrugated steel inclined web edge girder, see figure 1 :

[0027] Prefabricated concrete bottom slab: erect concrete bottom slab formwork, bind bottom slab steel bars, then connect corrugated steel oblique web 1a and corrugated steel straight web 2a to bottom slab reinforcement through shear keys (or other connection methods), pour bottom slab concrete to form side beams Bottom plate 3a;

[0028] Prefabricated concrete roof: set up the roof concrete formwork, tie the roof reinforcement, then connect the roof reinforcement with the corrugated steel oblique web 1a and corrugated steel straight web 2a through shear keys (or other connection methods), pour the roof concrete to form the edge Beam roof 4a;

[0029] When binding the steel bars, reserve the horizontal connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com