Winding method for oval multi-layer coil of transformer

A multi-layer coil and winding method technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. Improve mechanical strength and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing.

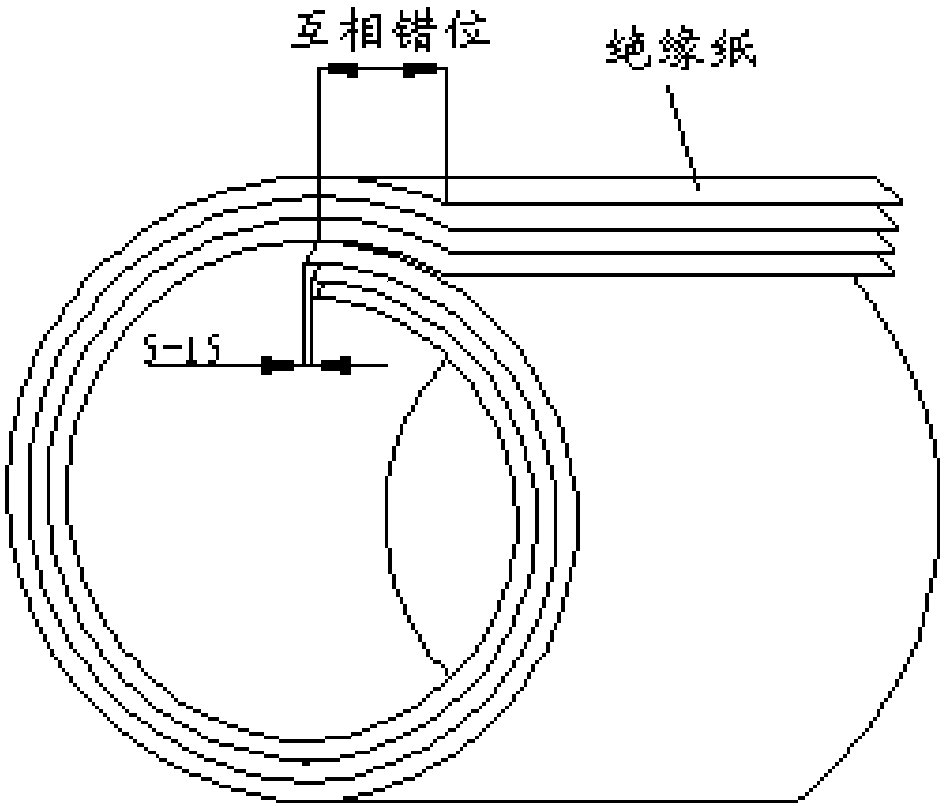

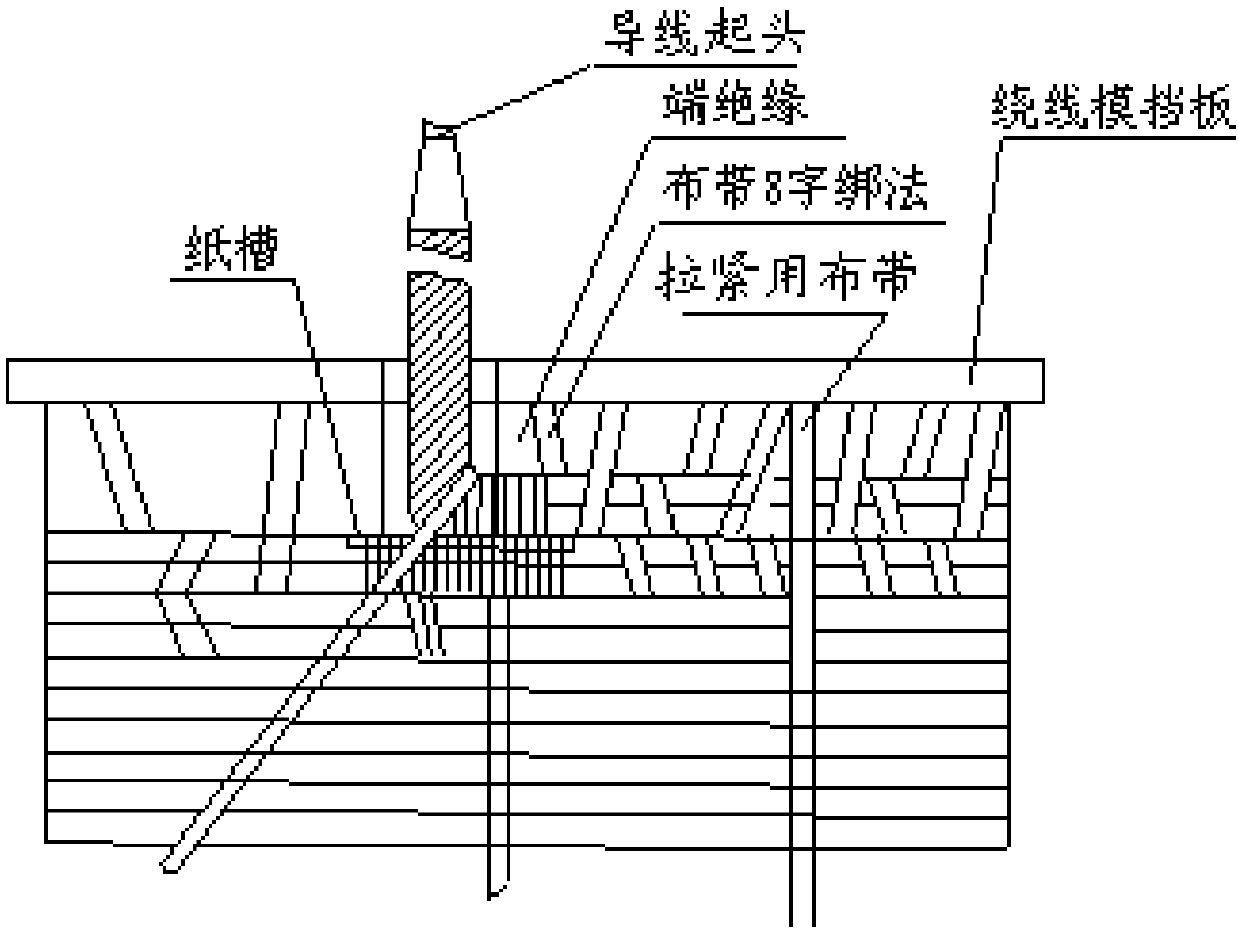

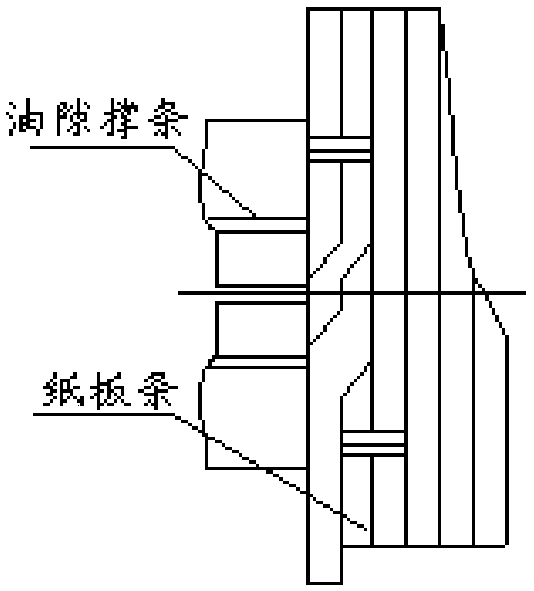

[0054] The transformer oval multilayer coil includes a low-voltage coil and a high-voltage coil coaxially located outside the low-voltage coil; both the low-voltage coil and the high-voltage coil are provided with oil channels, and the oil channels are made of corrugated cardboard, and the overlapping length of the corrugated cardboard joints is 15~ 30mm, the corrugated part of the overlapping part should be occluded. Interlayer insulation is provided between the layers of the low-voltage coil and between the layers of the high-voltage coil. The interlayer insulation is composed of multiple layers of insulating paper. The ends of each layer of insulating paper are staggered and the stagger distance is 5-15mm. Each sheet of insulating paper overlaps not less than 15mm (see figure 1 ); Both ends of the low-voltage coil and the high-voltage coil are provided with end insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com