Constant-temperature power distribution cabinet

A power distribution cabinet and constant temperature technology, which is applied in the substation/power distribution device shell, electrical components, substation/switch layout details, etc., to achieve the effect of increasing the speed and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

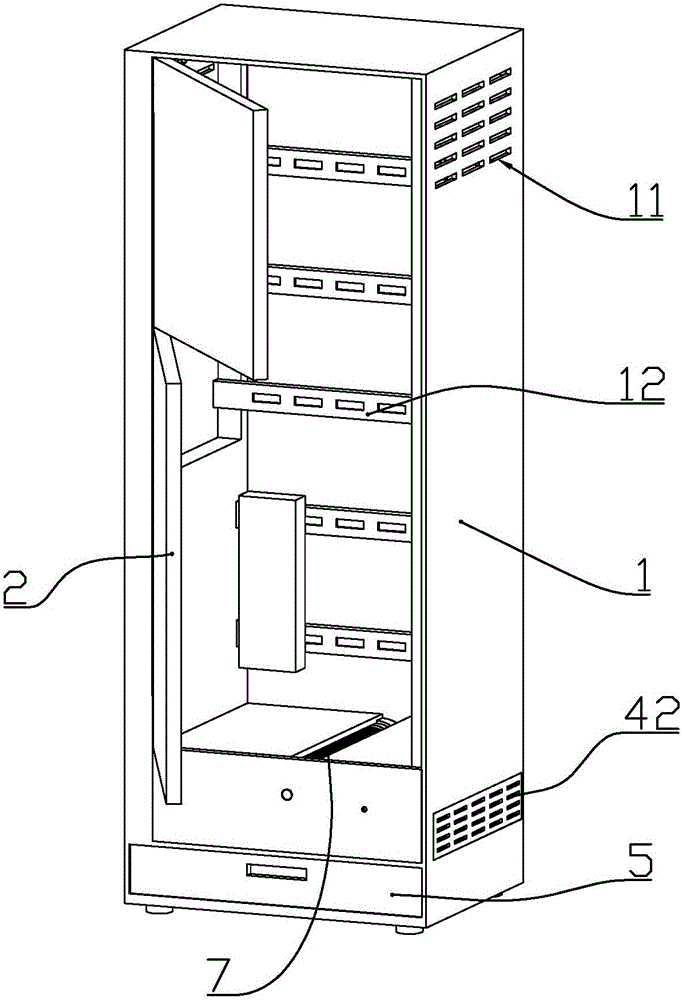

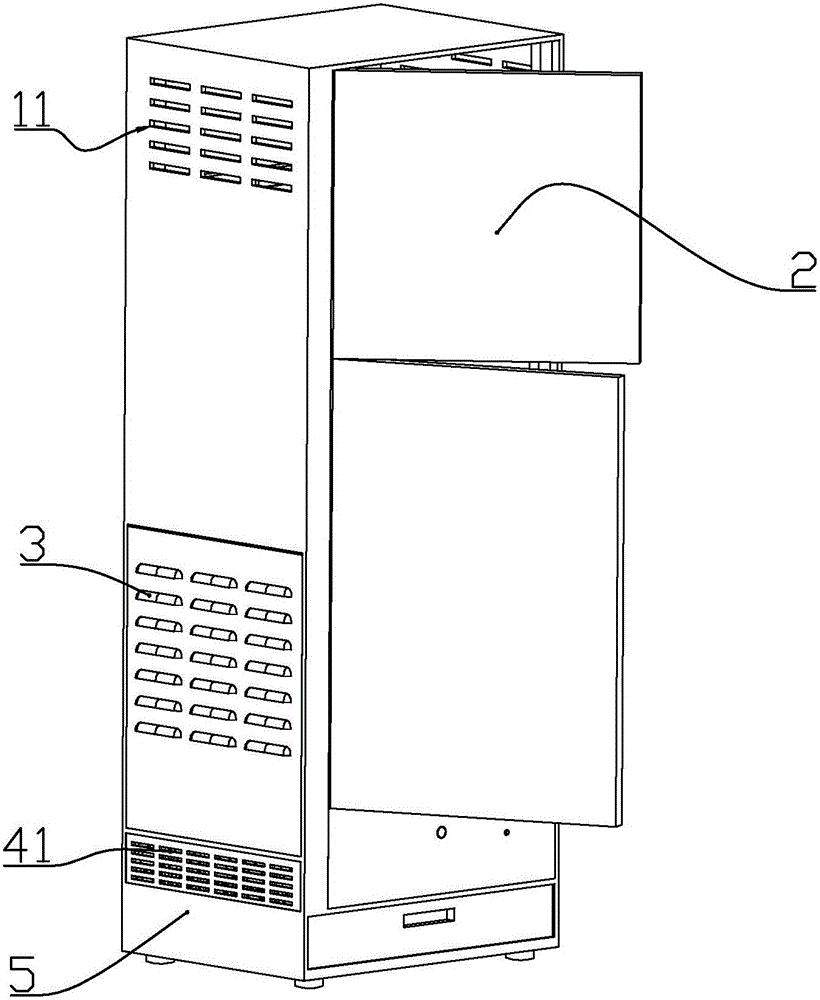

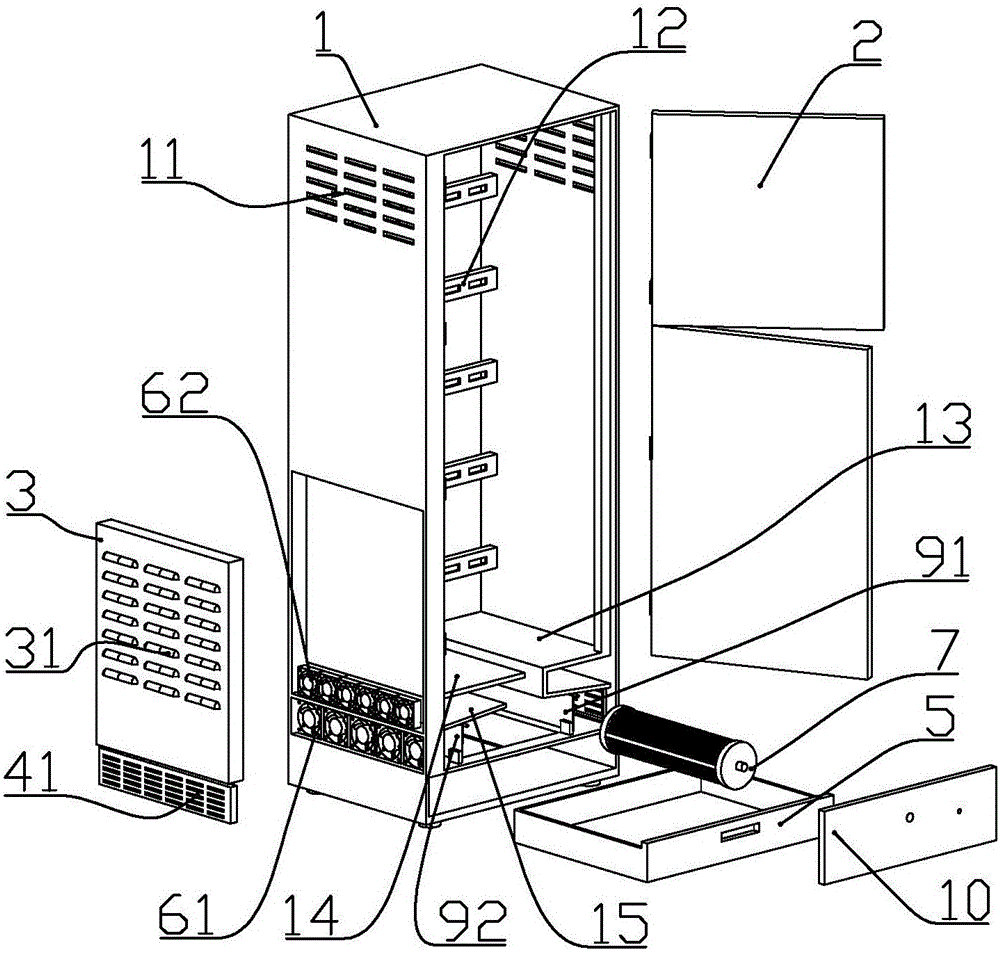

[0041] according to Figure 1 to Figure 13 As shown, this embodiment is a constant temperature power distribution cabinet, including a cabinet body 1 with an open front end, and a cabinet door 2 connected to the front end of the cabinet body through hinges; a mounting frame 12 is installed at the rear of the cabinet body.

[0042] The bottom of the cabinet body is formed with a slope plate 16 that is high on both sides and low in the middle; in the cabinet, the rear side of the cabinet is the rear cabinet, and the bottom of the rear cabinet is located above the middle of the slope. A stepper motor 8 is installed. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0043] The cooling chip assembly 7 includes two circular end blocks 74 of plastic material, more than one semiconductor cooling chip 71 connected between the two end blocks, a condensation aluminum seat 72 conne...

Embodiment 2

[0057] according to Figure 1 to Figure 13 As shown, this embodiment is a constant temperature power distribution cabinet, including a cabinet body 1 with an open front end, and a cabinet door 2 connected to the front end of the cabinet body through hinges; a mounting frame 12 is installed at the rear of the cabinet body.

[0058] The bottom of the cabinet body is formed with a slope plate 16 that is high on both sides and low in the middle; in the cabinet, the rear side of the cabinet is the rear cabinet, and the bottom of the rear cabinet is located above the middle of the slope. A stepper motor 8 is installed. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0059] The cooling chip assembly 7 includes two circular end blocks 74 of plastic material, more than one semiconductor cooling chip 71 connected between the two end blocks, a condensation aluminum seat 72 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com