Manufacturing method for embedded type circuit of PCB (Printed Circuit Board)

A manufacturing method and embedded technology, applied in printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of low circuit fineness and poor uniformity, and achieve stable embedded circuits, a wide range of applications, and improved integration. Effects of Density and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

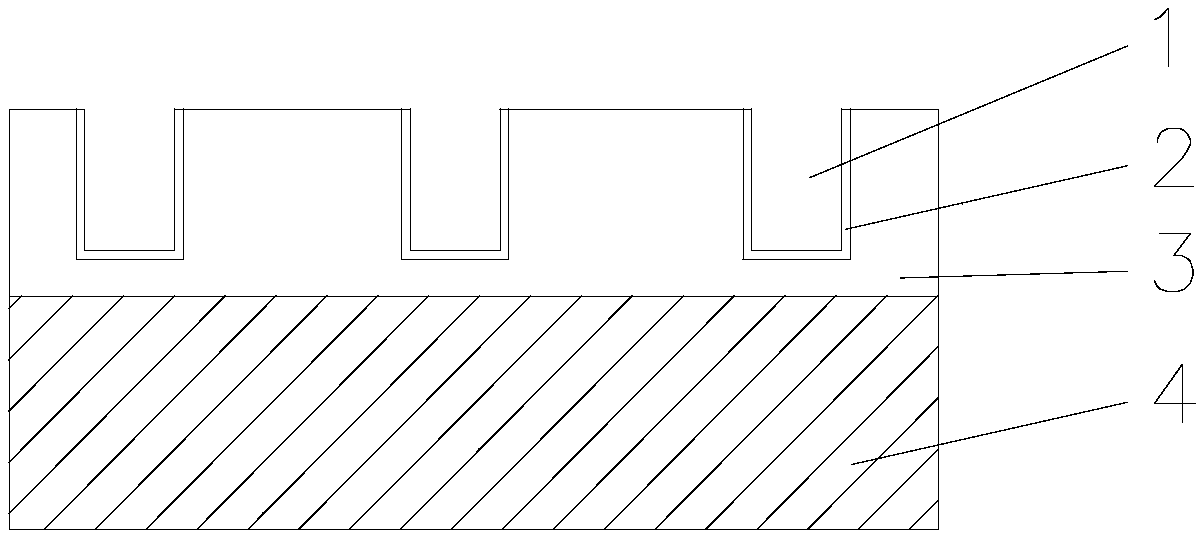

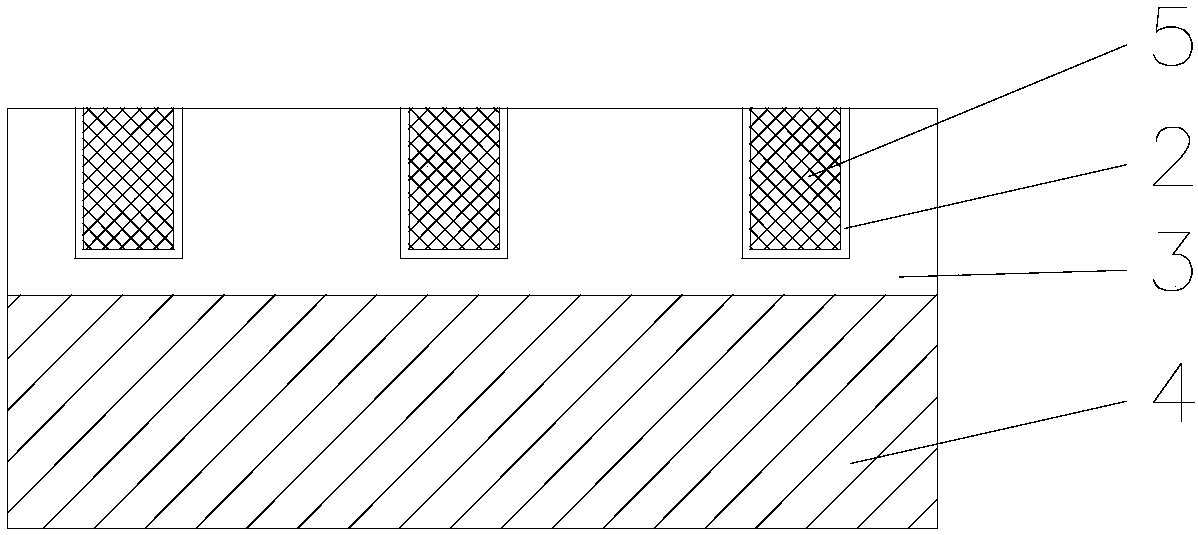

[0049] see figure 1 and figure 2, a method for manufacturing a PCB embedded circuit, comprising the following steps:

[0050] 1) Construct the motherboard

[0051] 1a) Clean the wafer with piranha solution at 100°C for 15 minutes, then clean it with deionized water, and then dry it.

[0052] 1b) Preheat the wafer at 115°C for 1 min.

[0053] 1c) The photoresist is then spin-coated on the wafer at a rotation speed of 2500 rpm for 30 s, and then baked at 110° C. for 1 min to remove the solvent in the photoresist.

[0054] 1d) Design a photomask according to the required circuit pattern, cover the photomask on the wafer, and then expose to UV light for 5-10s. In this embodiment, the line width and line spacing of the circuit pattern are both 2 µm, and the copper thickness is 2 µm.

[0055] 1e) Dip the wafer in the developer solution for 1 min, rinse it with deionized water, and dry it.

[0056] 1f) Etching the wafer obtained in step 1e), controlling the etching rate to 0.5...

Embodiment 2

[0081] see figure 1 and figure 2 , a method for manufacturing a PCB embedded circuit, comprising the following steps:

[0082] 1) Construct the motherboard

[0083] 1a) Clean the wafer with piranha solution at 125°C for 20 minutes, then clean it with deionized water, and then dry it.

[0084] 1b) Preheat the wafer at 115°C for 3 minutes.

[0085] 1c) The photoresist is then spin-coated on the wafer at a rotation speed of 3000 rpm for 30 s, and then baked at 110° C. for 1.5 min to remove the solvent in the photoresist.

[0086] 1d) Design a photomask according to the required circuit pattern, cover the photomask on the wafer, and then expose to UV light for 5-10s. In this embodiment, the line width and line spacing of the circuit pattern are both 10 µm, and the copper thickness is 20 µm.

[0087] 1e) Dip the wafer in the developer solution for 1.5 min, rinse it with deionized water, and dry it.

[0088] 1f) Etching the wafer obtained in step 1e), controlling the etching ...

Embodiment 3

[0113] see figure 1 and figure 2 , a method for manufacturing a PCB embedded circuit, comprising the following steps:

[0114] 1) Construct the motherboard

[0115] 1a) Clean the wafer with piranha solution at 150°C for 25 minutes, then clean it with deionized water, and then dry it.

[0116] 1b) Preheat the wafer at 115°C for 5 minutes.

[0117] 1c) The photoresist is then spin-coated on the wafer at a rotation speed of 3500 rpm for 30 s, and then baked at 110° C. for 2 min to remove the solvent in the photoresist.

[0118] 1d) Design a photomask according to the required circuit pattern, cover the photomask on the wafer, and then expose to UV light for 5-10s. In this embodiment, the line width and line spacing of the circuit pattern are both 80 μm, and the copper thickness is 200 μm.

[0119] 1e) Dip the wafer in the developer solution for 2 minutes, then rinse it with deionized water, and dry it.

[0120] 1f) Etching the wafer obtained in step 1e), controlling the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com