Gel paste composition and cosmetic using the gel paste composition

A technology for gel pastes and cosmetic materials, applied in cosmetics, cosmetics, cosmetic preparations, etc., which can solve problems such as difficulty in ensuring oil absorption, storage stability of thickened cosmetic materials, and insufficient compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] The following examples and comparative examples are given to describe the present invention more specifically, but the present invention is not limited by the following examples.

[0150] (A) Synthesis of cross-linked organopolysiloxane

Synthetic example 1

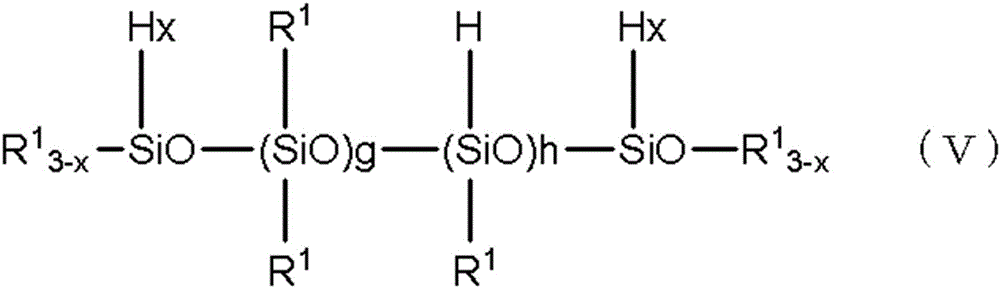

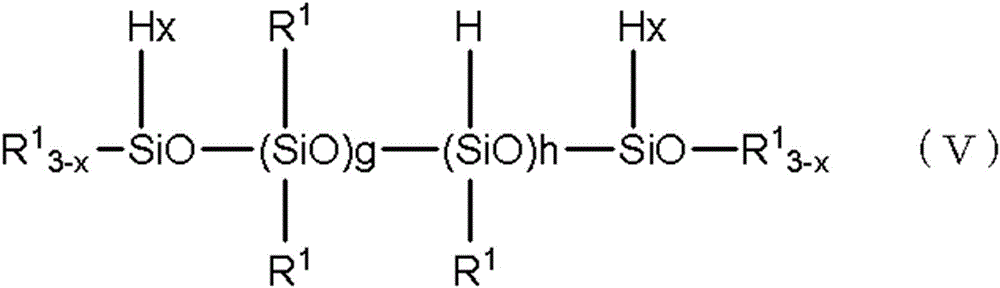

[0152] Add 83.2 g of organohydrogenpolysiloxane represented by the following average composition formula (1; set molecular weight 4162) and polyoxyalkylene represented by the following average composition formula (P1; set molecular weight 2878) to the reactor 143.9 g of base, 340 g of isopropanol, and 0.06 g of 3% by mass chloroplatinic acid ethanol solution, and stirring for 3 hours while maintaining the internal temperature at 70 to 80° C., thereby obtaining a polyoxyalkylene crosslinked organopolysiloxane .

[0153] And 45.4 g of 1% citric acid aqueous solutions were added and mixed, and it heat-processed for 3 hours maintaining internal temperature at 70-80 degreeC. Then, 36.3 g of 1% sodium bicarbonate aqueous solution was added, and it stirred for 1 hour maintaining internal temperature at 40-50 degreeC. After completion of the stirring, the internal temperature was heated to 100° C. under reduced pressure to remove volatile components to obtain an acid-treated polyoxya...

Synthetic example 2

[0157] 83.2 g of organohydrogenpolysiloxane represented by the above average composition formula (1), 150.9 g of polyoxyalkylene represented by the following average composition formula (P2; set molecular weight 3018), isopropyl 352 g of alcohol and 0.06 g of a 3% by mass chloroplatinic acid ethanol solution were stirred for 3 hours while maintaining the internal temperature at 70 to 80° C., thereby obtaining a polyoxyalkylene crosslinked organopolysiloxane.

[0158] And 46.8 g of 1% citric acid aqueous solutions were added and mixed, and it heat-processed for 3 hours maintaining internal temperature at 70-80 degreeC. Then, 37.4 g of 1% sodium bicarbonate aqueous solution was added, and it stirred for 1 hour maintaining internal temperature at 40-50 degreeC. After completion of the stirring, the internal temperature was heated to 100° C. under reduced pressure to remove volatile components to obtain an acid-treated polyoxyalkylene crosslinked organopolysiloxane.

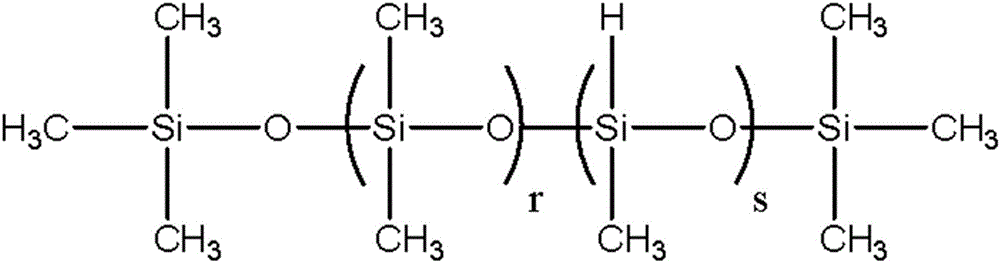

[0159] CH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com