Glue dipping production line for balancing block

A technology of balance block and production line, which is applied in the direction of coating, the device for coating liquid on the surface, etc., to ensure product quality and production efficiency, and the effect of even dipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings.

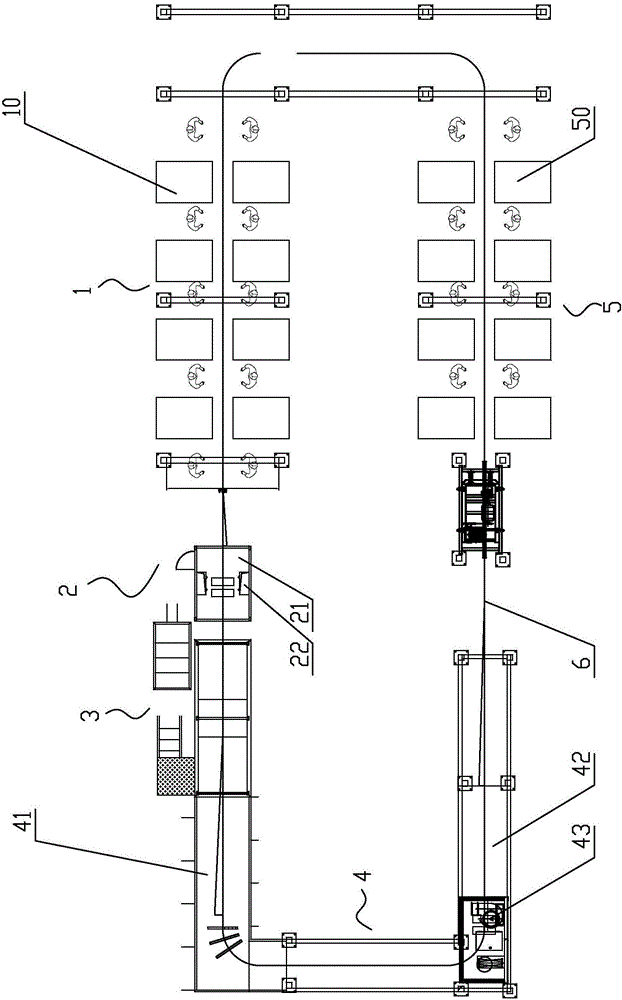

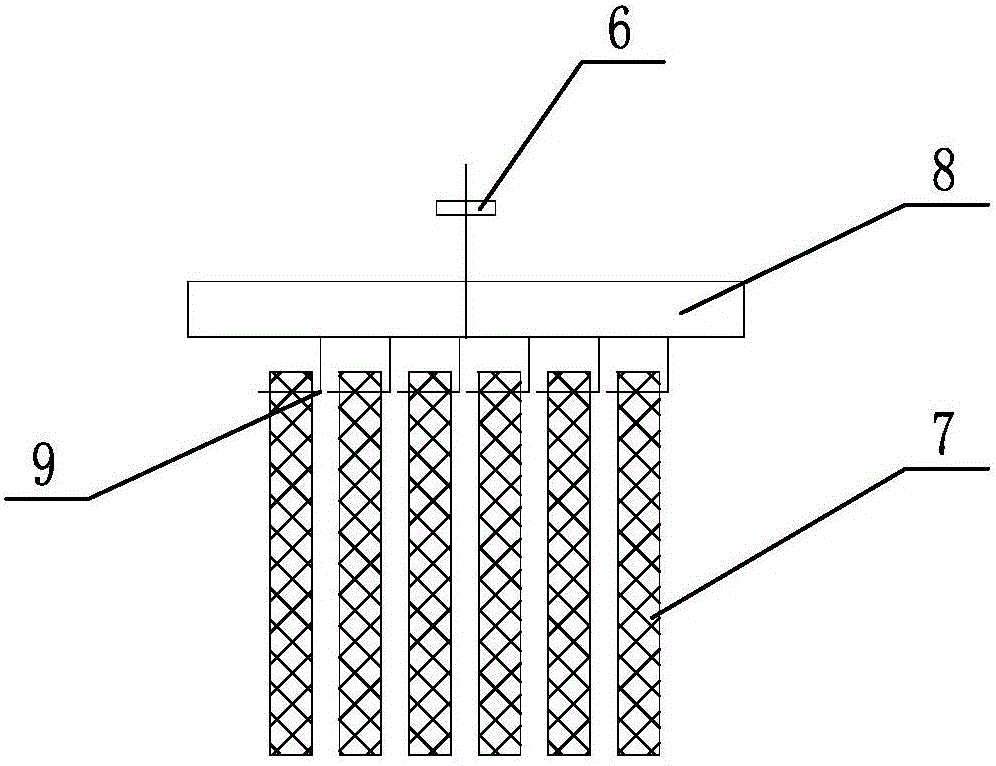

[0018] Such as Figure 1 ~ Figure 2 As shown: the balance weight dipping production line includes a feeding section 1, a dust removal section 2, a dipping section 3, a drying section 4, a feeding section 5, a transport chain 6, a balance piece workpiece 7, a hanger 8, and a hook 9. Feeding station 10, soot blowing chamber 21, air curtain machine and dust suction channel 22, leveling room 41, drying chamber 42, steam heater and fan 43, unloading station 50, etc.

[0019] Such as figure 1 As shown, the balance block dipping production line of the present invention includes a feeding section 1, a dust removal section 2, a dipping section 3, a drying section 4 and a blanking section 5 arranged in sequence, the feeding section 1, the dust removal section 2, A conveying track is set up between the dipping section 3, the drying section 4 and the unloading section 5, and the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com