On-machine laser direct detection device for profile accuracy of oil thread and measurement method

A laser direct, detection device technology, applied in tangent devices, measuring/indicating equipment, thread cutting auxiliary equipment, etc., can solve the problem of large lateral resolution, labor-intensive measurement, and inability to thread profile parameters and root profile accuracy Detection and other problems, to achieve the effects of great scientific research value, fast detection speed, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

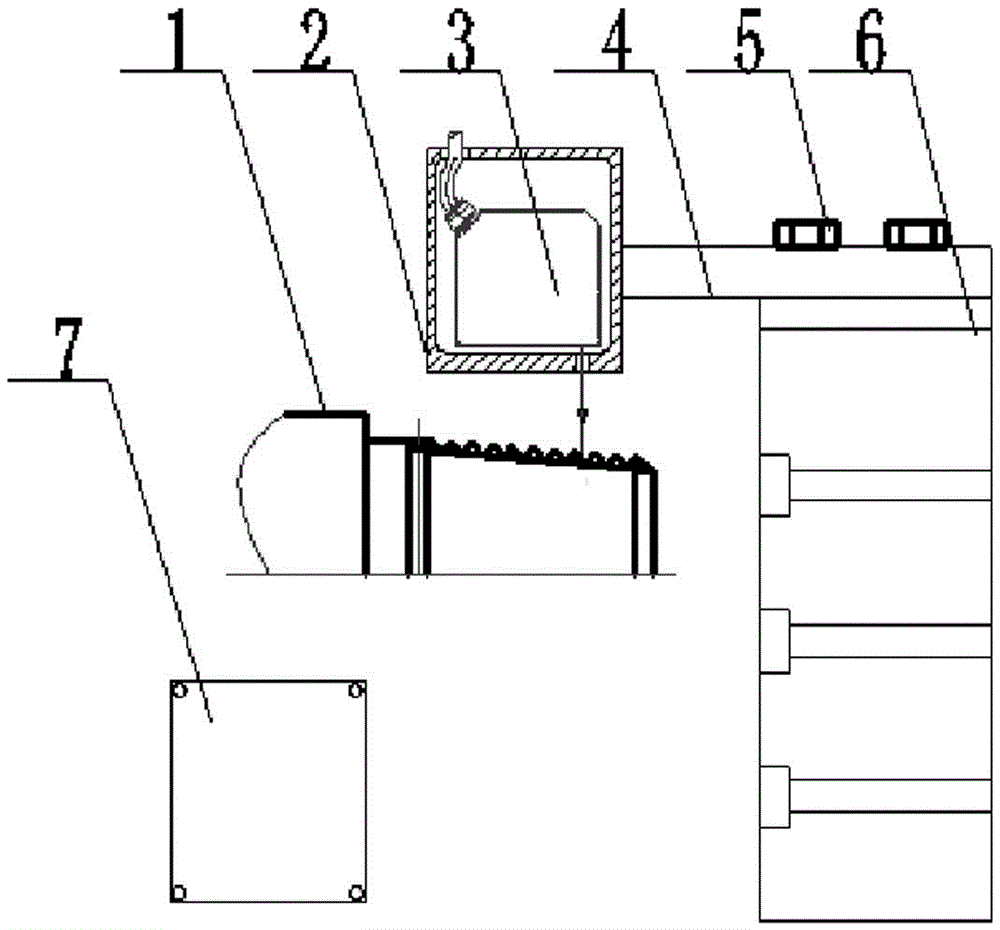

[0018] Such as figure 1 As shown, the present invention provides an on-machine laser direct detection device for petroleum thread profile accuracy,

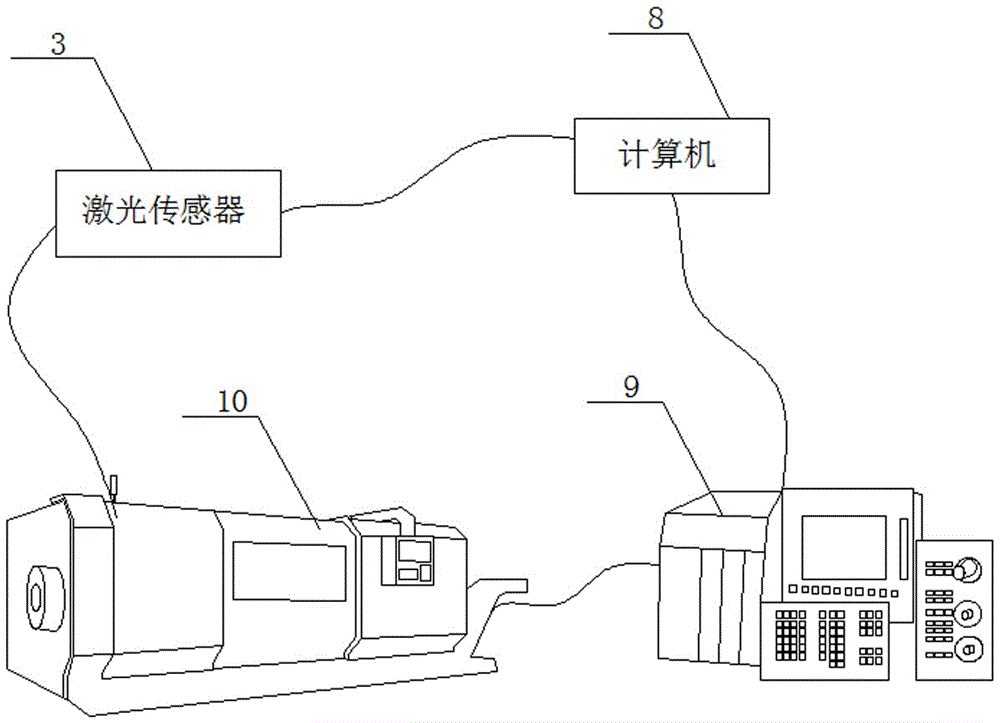

[0019] The present invention aims at the problems encountered in the detection of the current oil thread profile accuracy, and uses a laser displacement sensor to realize the non-contact on-machine direct detection of the thread profile accuracy. The displacement sensor completes the scanning of the axial tooth profile of the oil thread; the control device, centered on the computer, completes the processing of the detection data through numerical algorithms in the computer, and calculates all the parameters of the thread, judges the accuracy of the axial profile, and distinguishes Processing deviation, for unqualified workpieces, the computer will feed back the compensation results to the CNC system to control the change of the tool position on the machine tool. However, due to the large size of the laser sensor, it cannot enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com