3D printing system for prestressed piles and application method thereof

A technology of prestressed piles and 3D printing, applied in sheet pile walls, supply devices, infrastructure engineering, etc., can solve problems such as inconsistent pile lengths, inconsistent cross-sectional materials, and single cross-sectional forms of prestressed piles, so as to improve the bearing capacity of pile foundations performance, quality assurance and load bearing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

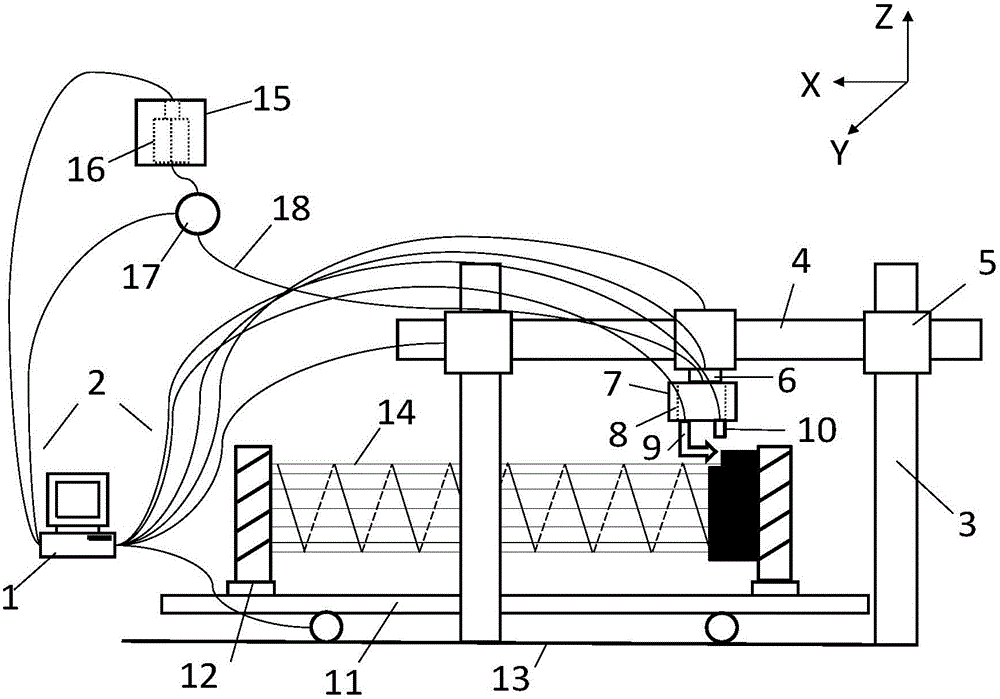

Embodiment 1

[0031] figure 1The prestressed pile 3D printing system includes: a control device 1, a space displacement device, a material supply device and a printing device; the control device 1 adopts a computer, and is connected to the space displacement device, the material supply device and the printing device through a data line 2 respectively , the spatial displacement device includes a printing mobile device and a prefabricated pile mobile device; the material supply device includes a material tank 15 and a feed pipe 18, a mixing unit 16 is arranged in the feed pool 15, and a slurry pump 17 is provided on the feed pipe 18; the printing device Comprising a material storage unit 7, a printing unit 9 and a solidification unit 10, the material storage unit 7 is connected to the material tank 15 through a feed pipe 18, and a heating unit 8 is arranged inside it, and the printing unit 9 and the solidification unit 10 are arranged on the material storage unit 7 below; the printing mobile ...

Embodiment 2

[0038] combine figure 1 and figure 2 In this embodiment, the method for printing prestressed piles by the prestressed pile 3D printing system in Embodiment 1 is introduced, including the following steps:

[0039] (1) 3D printing system installation: First, according to the design requirements, make a support frame with a length of 3-4m, a width of 2-3m, and a height of 1.5-2.5m. The horizontal support 4 and the vertical support 3 of the support frame are moved The devices are connected to each other; the Y slide rail 6 is connected to the transverse support 4 through the mobile device, and the storage device 7 is connected to the Y slide rail 6 through the mobile device; a heating device 8 is installed in the storage device 7, and Install the printing unit 9 and the solidification unit 10 side by side below it; connect the material pool 15, the stirring device 16, the feeding pipe 18, the slurry pump 17 and the material storage device 7 to form a material supply system; acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap