Noctilucent protection film capable of fitting with arc edge and preparation method thereof

A protective film and arc-fitting technology, applied in protective equipment, chemical instruments and methods, protective clothing, etc., can solve problems such as single function of protective film, inability to meet people's individual needs, and affect the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

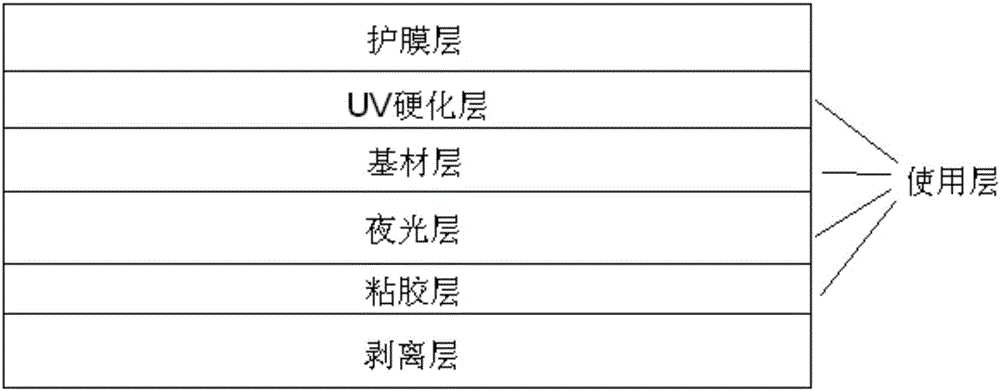

[0047] The invention provides a preparation method of a luminous protective film that can be attached to arc edges, comprising the following steps:

[0048] A) One side of the substrate layer is coated with UV-curable adhesive, and after UV-cured, a substrate compounded with a UV-curable layer is obtained; the UV-curable adhesive includes acrylate prepolymer resin, free radical curing monomer and photoinitiators;

[0049] B) printing the luminous glue on the other side of the base material compounded with the UV hardened layer in step A), and forming a luminous layer on the base material after heating and curing;

[0050] C) Coating viscose on the surface of the luminous layer, and forming a viscose layer after curing;

[0051] D) Attaching a peeling layer on the surface of the adhesive layer for use; compounding a protective film layer on the surface of the UV hardening layer of the use layer to obtain a luminous protective film that can be attached to arc edges.

[0052] I...

Embodiment 1

[0066] Mix 30 parts of butanone, 30 parts of propylene glycol methyl ether acetate, 50 parts of hexanediol diacrylate, 30 parts of epoxy acrylic resin, 15 parts of polyurethane acrylic resin, 4 parts of benzophenone and 1 part of triethanolamine to obtain Diluted UV curable adhesive.

[0067] Take a PET base material with a thickness of 20 μm, and coat one side of the PET base material with a UV curable adhesive with a thickness of 4 μm. After heating in an oven at 50°C, it is irradiated with a UV lamp for UV curing to obtain a base material with a UV hardened layer on one side. UV lamp energy is 500mJ / cm 2 .

[0068] Mix the silicone pressure-sensitive adhesive and the luminous powder according to the mass ratio of 1000:10, and use the method of ultrasonic dispersion and physical stirring to fully stir the glue for 1 hour to mix the glue evenly, and filter the glue with a 15 μm filter element to obtain the luminous glue liquid;

[0069] The luminous glue is printed on the ...

Embodiment 2

[0072] Mix 30 parts of butanone, 30 parts of propylene glycol methyl ether acetate, 60 parts of hexanediol diacrylate, 30 parts of epoxy acrylic resin, 15 parts of polyurethane acrylic resin, 2 parts of benzophenone and 1 part of triethanolamine to obtain Diluted UV curable adhesive.

[0073] Take a PET base material with a thickness of 80 μm, and apply UV-curable adhesive on one side of the PET base material with a thickness of 3 μm, heat it in an oven at 90°C, and then irradiate it with a UV lamp for UV curing to obtain a base material with a UV hardened layer on one side. UV lamp energy is 800mJ / cm 2 .

[0074] Mix the silicone pressure-sensitive adhesive and the luminous powder according to the mass ratio of 1000:20, and use the method of ultrasonic dispersion and physical stirring to fully stir the glue for 1 hour to mix the glue evenly, and filter the glue with a 15 μm filter element to obtain the luminous glue liquid;

[0075] The luminous glue is printed on the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com