A new type of passenger car chassis power platform

A bus chassis and power technology, applied in rolling resistance optimization, axles, wheels, etc., can solve the problems of handling stability, ride comfort, low NVH performance, unoptimized shortcomings, and bulky, etc., to improve traffic performance, Improved convenience and simplified assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

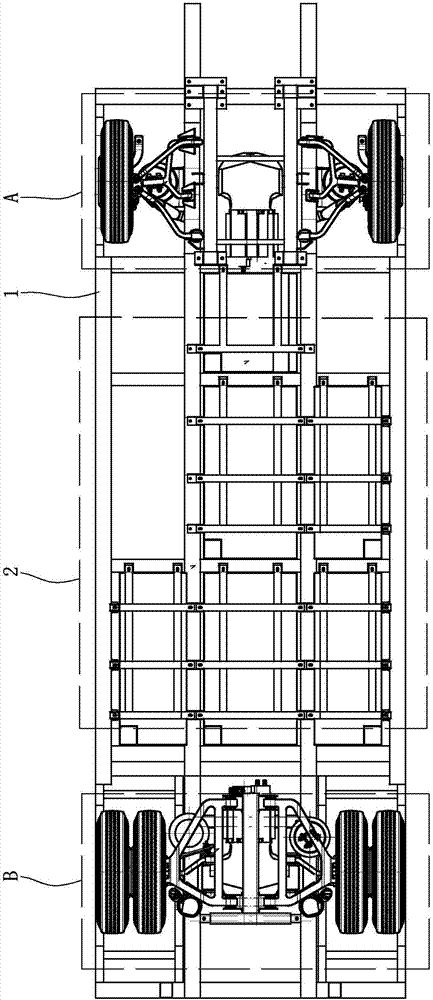

[0027] Such as figure 1 As shown, the power platform of the new bus chassis consists of four parts: the lower body frame 1, the power battery pack 2, the front drive steering axle A and the rear drive axle B. Wherein, the power battery pack 2 is installed in the middle part of the lower body frame 1, the front drive steering axle A is arranged at the front end of the lower body frame 1, and the rear drive axle B is arranged at the rear end of the lower body frame 1.

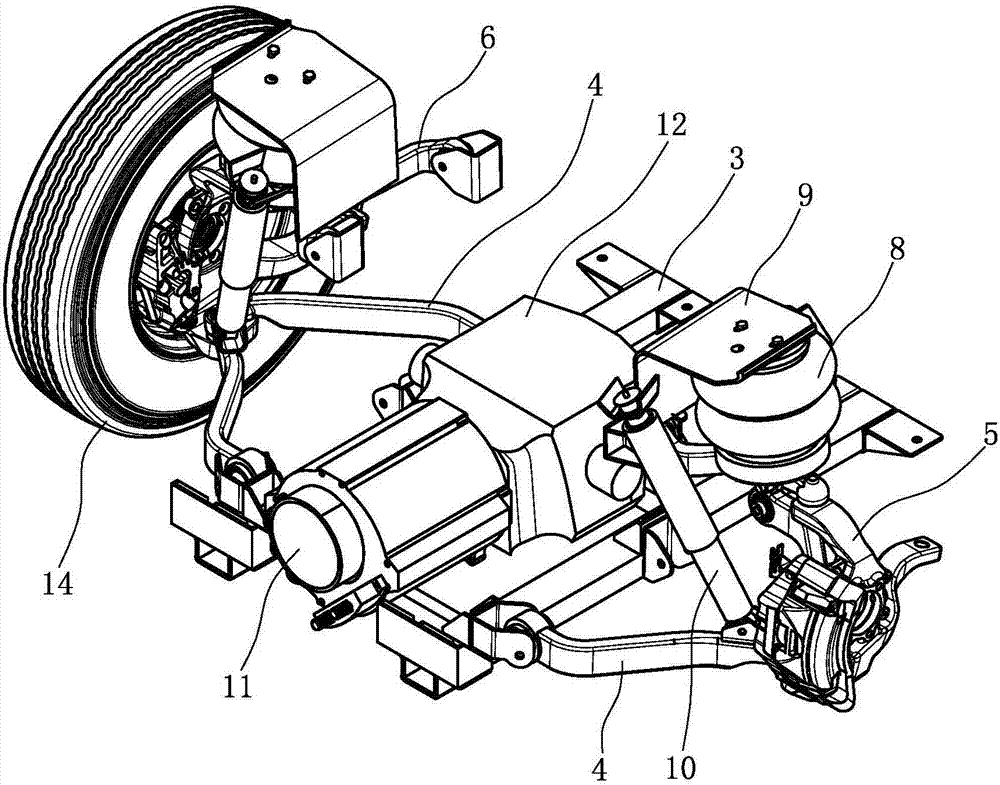

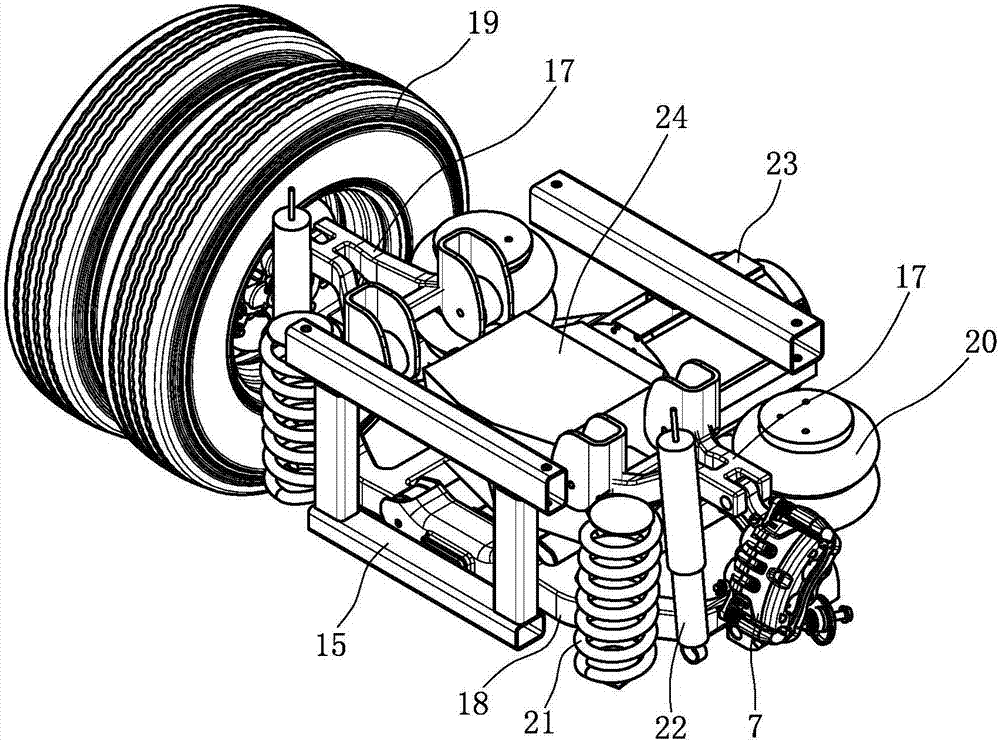

[0028] Such as figure 1 , figure 2 and Figure 4 As shown, the structure and installation method of the front drive steering axle A are as follows:

[0029] The front drive axle support 3 is a frame structure, and is preferably made of steel or aluminum alloy. The front drive axle support 3 is fixed on the lower vehicle body frame 1 . A group of front lower swing arms 4 are respectively ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com