A kind of manufacturing method of double-layer art glass

A manufacturing method and glass technology, which are applied in glass manufacturing equipment, glass forming, glass blowing, etc., can solve the problems of easy residual dirt on the inner wall of the bottom of the glass, long design and processing cycle, and difficulty in forging and processing. Improve the success rate and surface accuracy, beautiful appearance, shorten the effect of manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

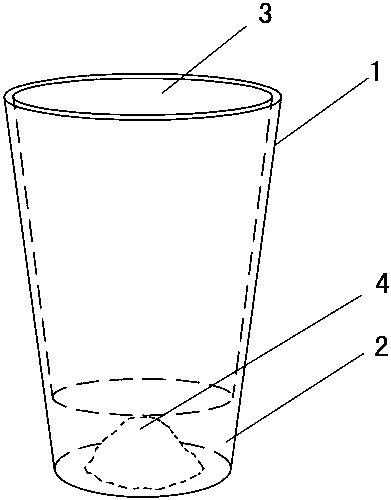

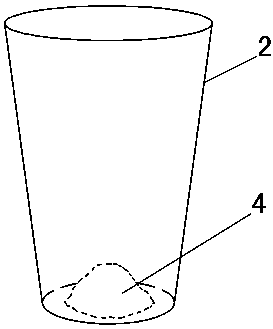

[0026] The application of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] a. According to the size requirements of the prepared double-layer art glass 1, use SolidWorks, AutoCAD, Rhino and other three-dimensional software to build a solid single-layer glass model file with a mountain-shaped notch 4 at the bottom of the cup, and then import it into a 3D printer , use a 3D printer to print the single-layer glass model. The single-layer glass model is solid and does not have a cavity to accommodate liquid. The printing material is gypsum powder;

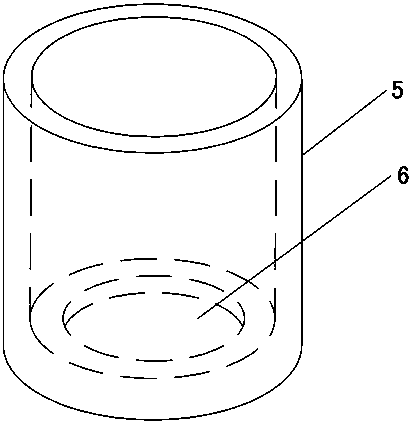

[0028] b. Turn the solid single-layer glass model printed in step a upside down in the mold manufacturing container 5 to form a mold, pour molten metal into the mold, and obtain a special glass mold after cooling, solidification, and cleaning , the center of the bottom of the mold manufacturing container 5 is provided with a container notch 6 corresponding to the mouth of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com