Sulfonated acetone-formaldehyde-amine fluorescent polymer as well as preparation method and application thereof

A technology of fluorescent polymer and sulfonated acetone, applied in the field of fluorescent polymer materials, can solve the problems of expensive raw materials, complex synthesis steps and the like, and achieve the effects of good water solubility, simple preparation process and high fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

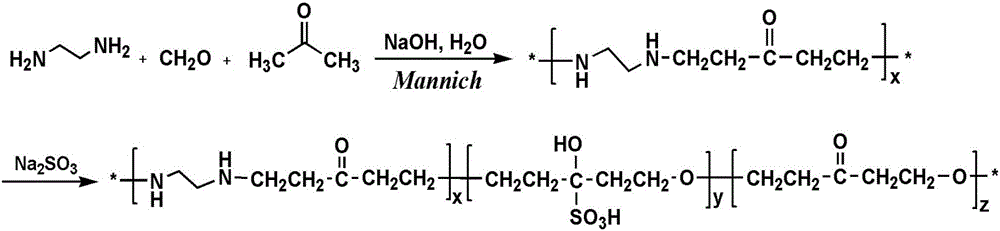

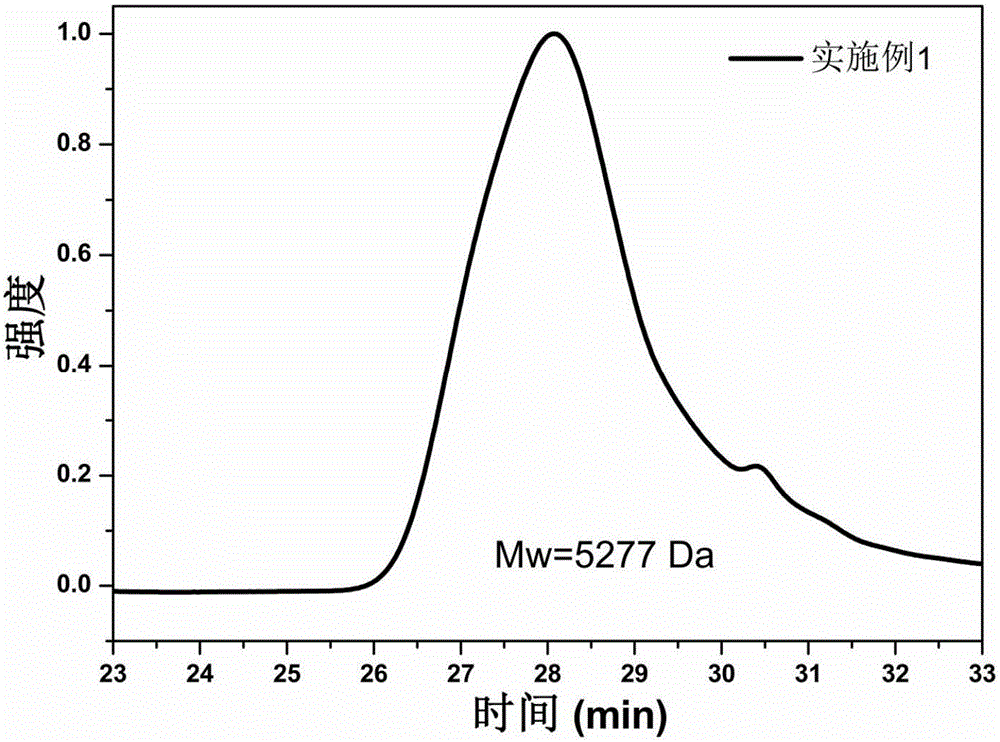

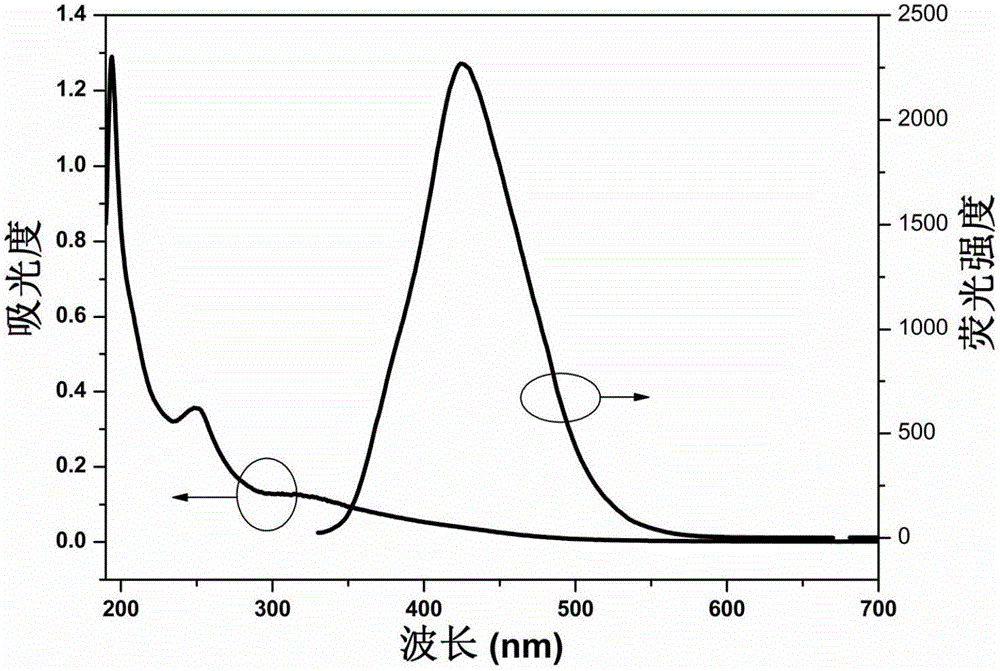

[0033] Use 1.2g NaOH solid to prepare NaOH aqueous solution with pH=12, take 5.0mL ethylenediamine liquid and add dropwise to the above alkaline solution, then add dropwise 6.16mL acetone and 5.74mL aqueous formaldehyde solution with a mass fraction of 37%, and stir under reflux at 40°C React for 30min; then add 5.24g of Na 2 SO 3 Solid, heat up to 70°C in a closed environment, continue to reflux for 5 hours; rotate the obtained reaction solution at 50°C to remove residual acetone and formaldehyde, adjust the pH to 2 with HCl solution with a mass fraction of 20%, put it into a dialysis bag for dialysis Purify for 7 days, then concentrate and freeze-dry to obtain a powdery solid product, which is a sulfonated acetone-formaldehyde-amine fluorescent polymer. The synthetic route diagram of the polymer obtained in the present embodiment is as follows figure 1 shown.

Embodiment 2

[0035] Use 0.5g of KOH solid to prepare KOH aqueous solution with pH=10, take 2.0g of 1,5-pentanediamine liquid and add dropwise to the above alkaline solution, then add dropwise 8.2mL of acetone and 11.5mL of 37% formaldehyde aqueous solution, 50 The reaction was stirred at reflux for 1 h at ℃; then 6.75 g of K was added 2 SO 3 Solid, continue to react at 85°C for 4h; Rotate the obtained reaction solution at 50°C for 30min to remove residual acetone and formaldehyde, then adjust the pH to 3 with HCl solution with a mass fraction of 20%, put it into a dialysis bag for dialysis and purification for 5 days, After concentrating and freeze-drying, a yellow powdery solid product is obtained, which is a sulfonated acetone-formaldehyde-amine fluorescent polymer.

Embodiment 3

[0037] Take 5.0g of 1,8-octanediamine and add it to the pre-prepared KOH aqueous solution (0.6g KOH solid) with pH = 11, stir until it is completely dissolved, then add 16.8mL of acetone and 20.0mL of formaldehyde aqueous solution (37%, wt%), stir vigorously to make it evenly mixed, heat up to 60°C for reflux reaction for 30min; then add 8.56g of Na 2 SO 3 Solid, continue to react at 85°C for 4h; Rotate the reaction solution at 50°C for 30min to remove residual acetone and formaldehyde, then use HNO 3 The pH of the solution (20%, wt%) was adjusted to 3, and a large amount of white solid was precipitated, which was filtered, rinsed with pure water, and vacuum-dried to obtain a white powdery solid product, which was a sulfonated acetone-formaldehyde-amine fluorescent polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com