Intumescent flame retardant containing polyhydroxy groups and two triazine rings and preparation method

The technology of an intumescent flame retardant and a hydroxybistriazine ring is applied in the field of intumescent flame retardants containing a polyhydroxybistriazine ring and its preparation, and can solve the problems of large quantities, great environmental and human hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

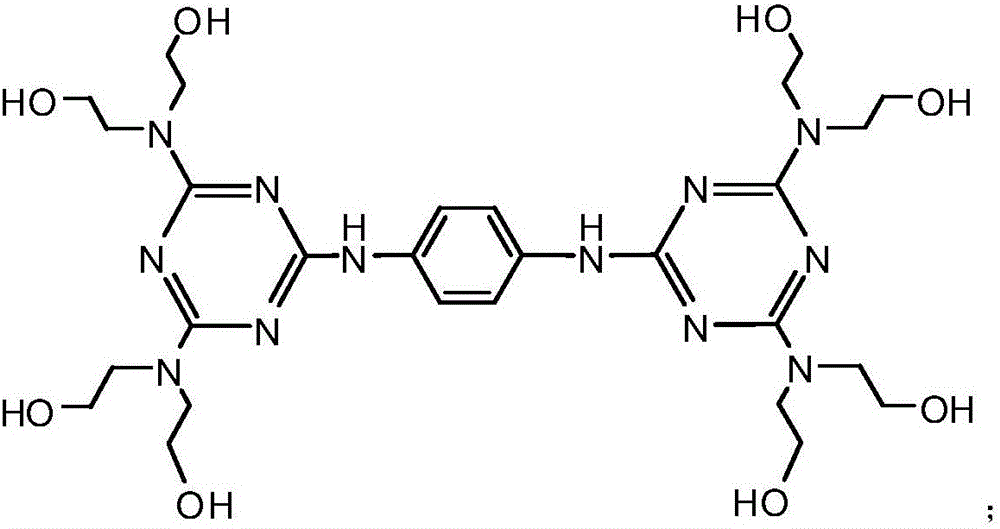

Embodiment 1

[0034] Add 18.45g of cyanuric chloride and 100ml of acetone solution (the volume ratio of acetone and water is 1:1) in the 1L reaction flask equipped with reflux condenser, constant pressure dropping funnel, stirrer and thermometer, fully stir, Make the cyanuric chloride disperse evenly, and then add 10.5g of diethanolamine and NaHCO dropwise evenly and slowly under the condition of 0°C while stirring. 3 solution (8.4g NaHCO 3 dissolved in 100ml distilled water), after the dropwise addition was completed, the reaction was carried out at 0° C. for 3 hours. Then raise the temperature to 40°C, add 100ml of acetone solution, and then evenly and slowly add 10.5g of diethanolamine and NaHCO 3 solution (8.4g NaHCO 3Dissolve in 100ml distilled water), keep the temperature at 40°C, after the dropwise addition is complete, react under this condition for 8 hours. Then heat up to 60°C, distill off acetone, then continue to heat up to 90°C, and slowly add 5.4g of p-phenylenediamine and ...

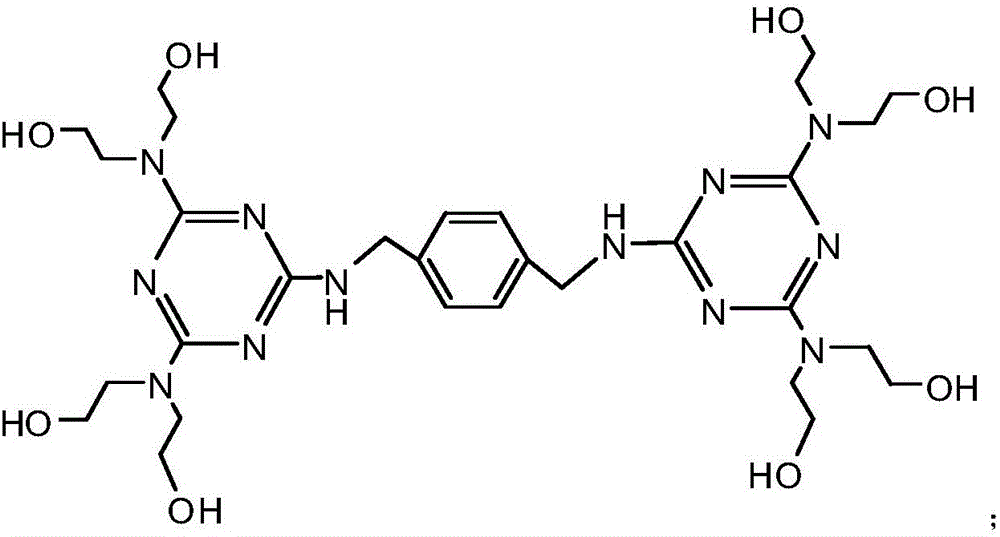

Embodiment 2

[0038] Add 18.45g of cyanuric chloride and 100ml of acetone solution (the volume ratio of acetone and water is 1:1.5) in the 1L reaction flask equipped with reflux condenser, constant pressure dropping funnel, stirrer and thermometer, fully stir, Disperse the cyanuric chloride evenly, and then add 10.5g of diethanolamine and NaHCO dropwise evenly and slowly under the condition of -5°C while stirring. 3 solution (8.4g NaHCO 3 dissolved in 100ml of distilled water), after the dropwise addition was completed, the reaction was carried out at -5°C for 4 hours. Then raise the temperature to 50°C, add 100ml of acetone solution, and then evenly and slowly add 10.5g of diethanolamine and NaHCO 3 Solution (8.4gNaHCO 3 Dissolve in 100ml distilled water), keep the temperature at 50°C, after the dropwise addition is complete, react under this condition for 6 hours. Then heat up to 60°C, distill off acetone, then continue to heat up to 100°C, evenly and slowly add 6.8g of p-xylylenediami...

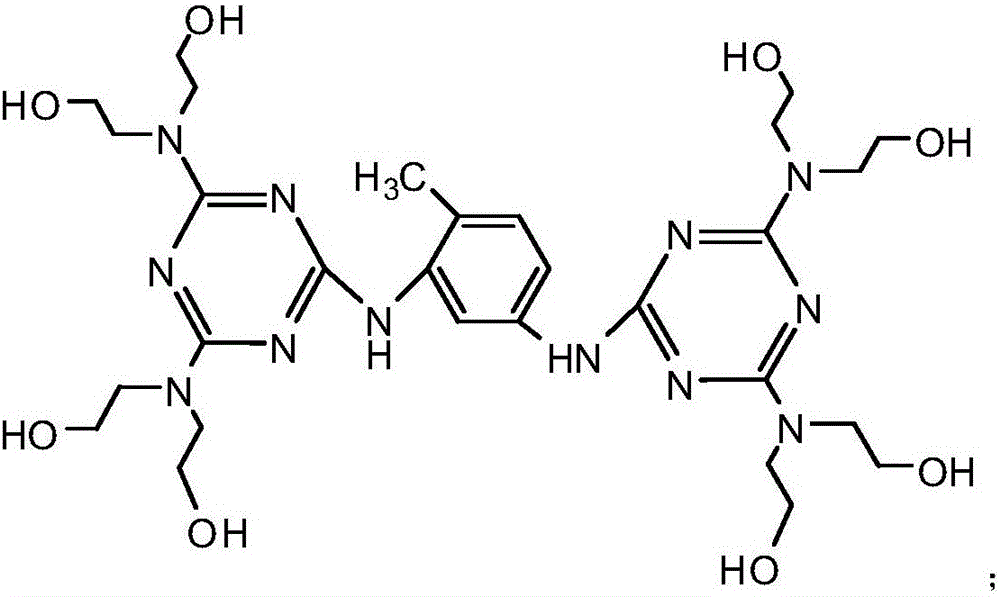

Embodiment 3

[0042] Add 18.45g of cyanuric chloride and 100ml of acetone solution (the volume ratio of acetone and water is 1:1) in the 1L reaction flask equipped with reflux condenser, constant pressure dropping funnel, stirrer and thermometer, fully stir, Make the cyanuric chloride disperse evenly, then under the condition of 5℃, add 10.5g diethanolamine and NaHCO dropwise evenly while stirring 3 solution (8.4g NaHCO 3 Dissolved in 100ml distilled water), after the dropwise addition was completed, reacted at 5°C for 3 hours. Then raise the temperature to 45°C, add 100ml of acetone solution, and then evenly and slowly add 10.5g of diethanolamine and NaHCO 3 solution (8.4g NaHCO 3 Dissolve in 100ml distilled water), keep the temperature at 45°C, after the dropwise addition is complete, react under this condition for 7 hours. Then the temperature was raised to 60°C, the acetone was distilled off, and then the temperature was continued to rise to 95°C, and 6.15g of 2,4-diaminotoluene and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com