Water quenching device for direct reduced iron (DRI) produced by rotary hearth furnace and method

A rotary hearth furnace, direct technology, applied in furnaces, fluidized bed furnaces, furnace types, etc., can solve problems such as equipment stuck, equipment aging, increased resistance, etc., to achieve convenient maintenance and replacement, low cooling water cost, and operation. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

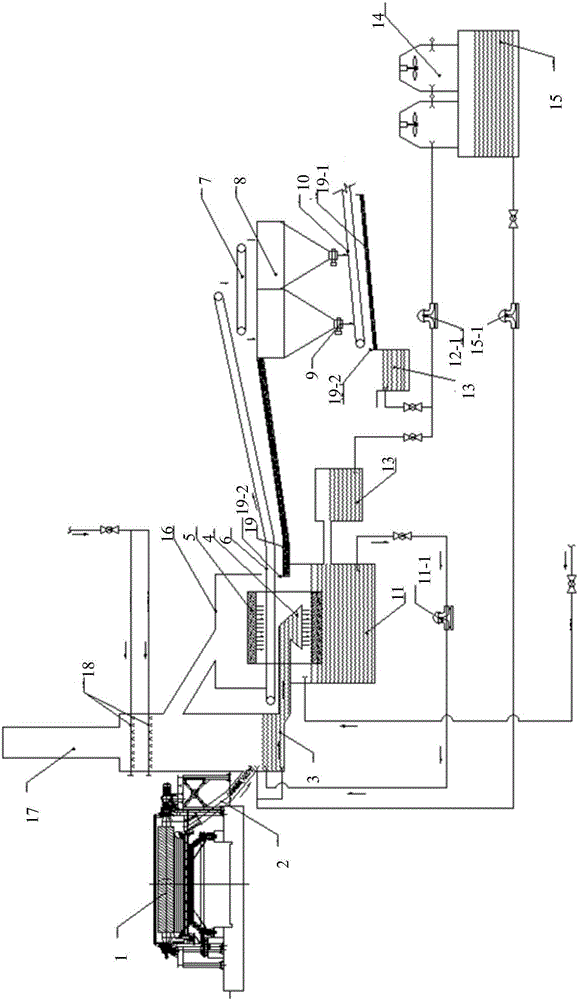

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, the present invention discloses a rotary hearth furnace direct reduction iron water quenching device, including a rotary hearth furnace 1 for producing high-temperature direct reduced iron, a punching device 3, and a hot DRI slide pipe 2 connecting the rotary hearth furnace 1 and the punching device 3 , a hot water pool 11, a distributor 4 extending from the brewing device 3 into the hot water pool 11, a first conveying device 6 above the distributor 4 (a belt conveyor 6 in this embodiment), a horizontal cylindrical centrifugal dehydrator 5. The storage bin 8 located below the output end of the first conveying device 6, the second conveying device 10 (in this embodiment, a belt conveyor 10) located below the outlet of the storage bin 8, the second conveying device 10 located at The sump 13 below the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com