Method for leaching uranium in radioactive alkali residues

A radioactive and alkaline slag technology, applied in the field of uranium leaching, can solve the problems of high recovery value, high leaching cost, and complicated leaching process, and achieve the effects of high leaching rate, low leaching cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

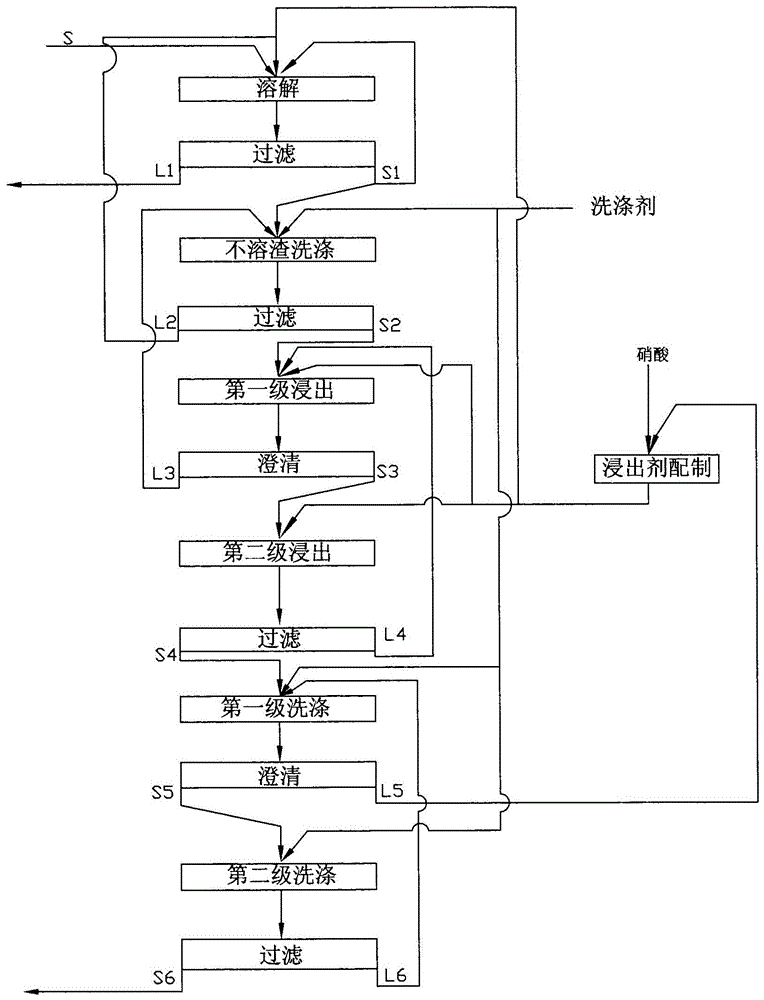

[0034] Embodiment 1. A method for leaching uranium from radioactive alkali slag. The radioactive alkali slag is finally formed by calcination at 800°C after filtering the uranium-containing waste slag obtained by precipitation under alkaline conditions during the treatment of uranium-containing wastewater. Dry alkali slag, this method adopts multi-stage countercurrent dissolution and leaching, mainly including: cyclic dissolution of alkali slag-filtration-insoluble slag washing-filtration-insoluble slag first-stage leaching-clarification-insoluble slag second-stage leaching-filtration-leaching slag second First stage washing - clarification - leaching slag Second stage washing - filtration, the specific process is as follows:

[0035] A. Alkali slag is dissolved in circulation

[0036] Add alkali slag S and leaching agent into the dissolution tank, the ratio of alkali slag and leaching agent is 1: 1, the leaching agent is nitric acid solution with a concentration of 50%, the d...

Embodiment 2

[0047] Embodiment 2. A method for leaching uranium from radioactive alkali slag. The radioactive alkali slag is finally formed by calcination at 800°C after filtering the uranium-containing waste slag obtained by precipitation under alkaline conditions during the treatment of uranium-containing wastewater Dry alkali slag, this method adopts multi-stage countercurrent dissolution and leaching, mainly including: cyclic dissolution of alkali slag-filtration-insoluble slag washing-filtration-insoluble slag first-stage leaching-clarification-insoluble slag second-stage leaching-filtration-leaching slag second First stage washing - clarification - leaching slag Second stage washing - filtration, the specific process is as follows:

[0048] A. Alkali slag is dissolved in circulation

[0049] Add the alkali slag S and the leaching agent into the dissolution tank, the ratio of the alkali slag and the leaching agent is 1: 2.5, the leaching agent is a nitric acid solution with a concentr...

Embodiment 3

[0060] Example 3. A method for leaching uranium from radioactive alkali slag. The radioactive alkali slag is finally formed by calcination at 800°C after filtering the uranium-containing waste slag obtained by precipitation under alkaline conditions during the treatment of uranium-containing wastewater Dry alkali slag, this method adopts multi-stage countercurrent dissolution and leaching, mainly including: cyclic dissolution of alkali slag-filtration-insoluble slag washing-filtration-insoluble slag first-stage leaching-clarification-insoluble slag second-stage leaching-filtration-leaching slag second First stage washing - clarification - leaching slag Second stage washing - filtration, the specific process is as follows:

[0061] A. Alkali slag is dissolved in circulation

[0062] Add alkali slag S and leaching agent into the dissolution tank, the ratio of alkali slag and leaching agent is 1: 5, the leaching agent is nitric acid solution with a concentration of 10%, the disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com