Copper alloy conductive screw for nuclear power and preparation method thereof

A conductive screw and copper alloy technology, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of insufficient core strength and stricter core strength requirements in the nuclear power industry, and achieve high hardness and high The effect of strength and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

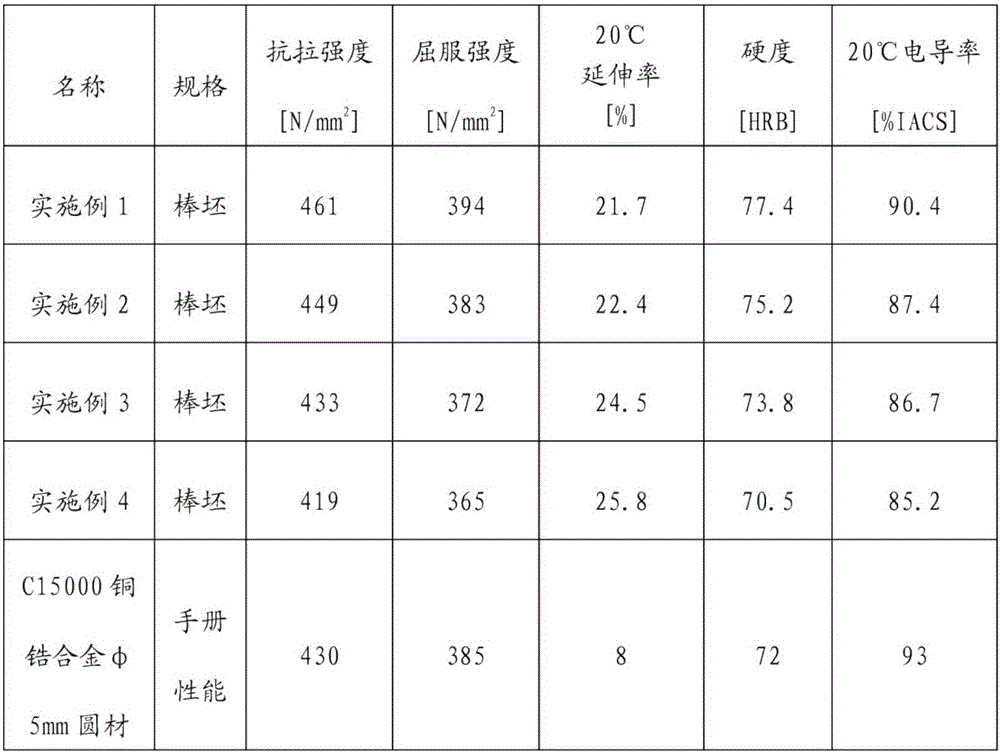

Examples

Embodiment 1

[0021] Based on the percentage content of the total weight of the copper-zirconium alloy: zirconium accounts for 0.15%, copper accounts for 99.82%, and the impurity content is 0.03%.

[0022] Preparation method: put copper and zirconium in a vacuum melting furnace, and after melting at 1220°C, cast them into alloy ingots; hot forging (heating temperature 950°C, holding time 3 hours), solid solution ( Heating temperature 940°C, holding time 80 minutes), secondary forging (heating temperature 480°C, holding time 2 hours, deformation 45%), aging (heating temperature 440°C, holding time 3 hours) treatment process, made About 177kg heavy copper zirconium alloy rod.

Embodiment 2

[0024] Based on the percentage of the total weight of the copper-zirconium alloy: zirconium accounts for 0.18%, copper accounts for 99.80%, and the impurity content is 0.02%.

[0025] Preparation method: put copper and zirconium in a vacuum melting furnace, and after melting at 1280°C, cast them into alloy ingots; hot forging (heating temperature 970°C, holding time 1.5 hours), solid solution ( Heating temperature 950°C, holding time 75 minutes), secondary forging (heating temperature 500°C, holding time 1 hour, deformation 40%), aging (heating temperature 420°C, holding time 5 hours) treatment process, made About 177kg heavy copper zirconium alloy rod.

Embodiment 3

[0027] Based on the percentage content of the total weight of the copper-zirconium alloy: zirconium accounts for 0.20%, copper accounts for 99.78%, and the impurity content is 0.02%.

[0028] Preparation method: put copper and zirconium in a vacuum melting furnace, and after melting at 1250°C, cast them into alloy ingots; hot forging (heating temperature 930°C, holding time 3 hours), solid solution ( Heating temperature 960°C, holding time 30 minutes), secondary forging (heating temperature 440°C, holding time 4 hours, deformation 35%), aging (heating temperature 400°C, holding time 6 hours) treatment process, made About 177kg heavy copper zirconium alloy rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com