Structure for preventing bridge from overturning transversely and construction method of structure

A technology of lateral overturning and construction, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of weak anti-overturning ability, achieve the effect of easy material selection, reasonable force, and avoid vertical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, structure of the present invention, construction process are further described as follows.

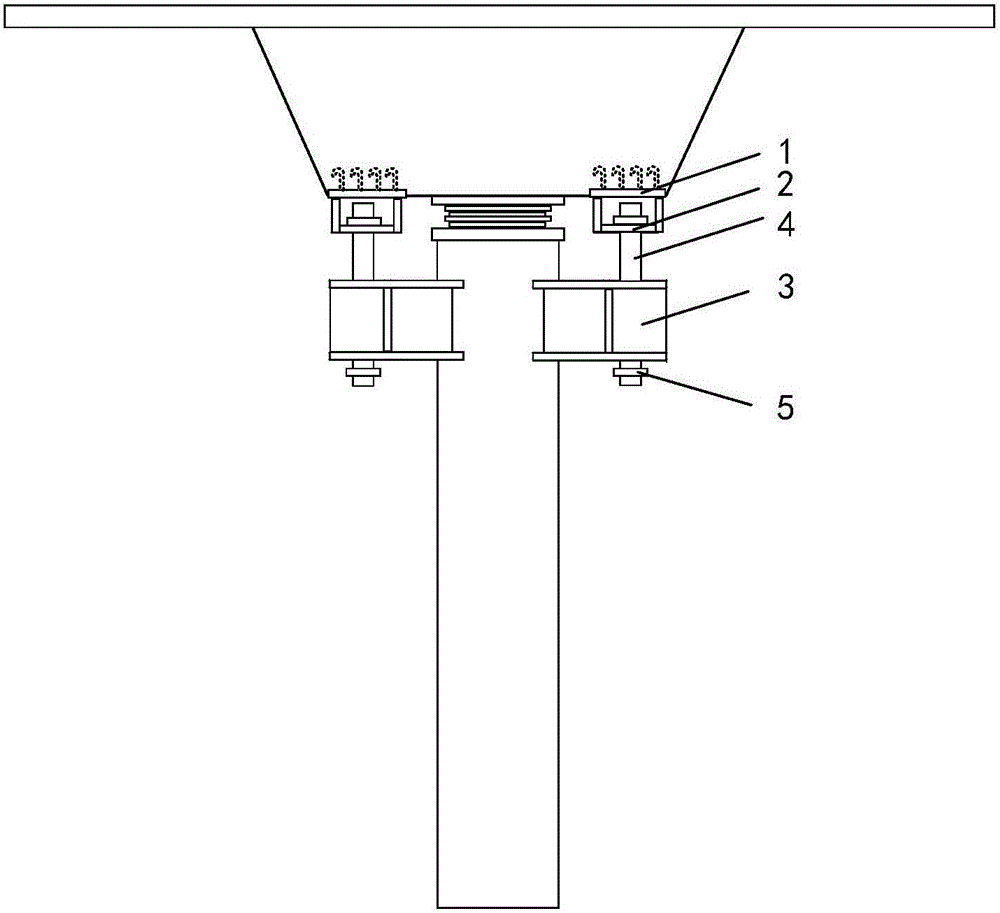

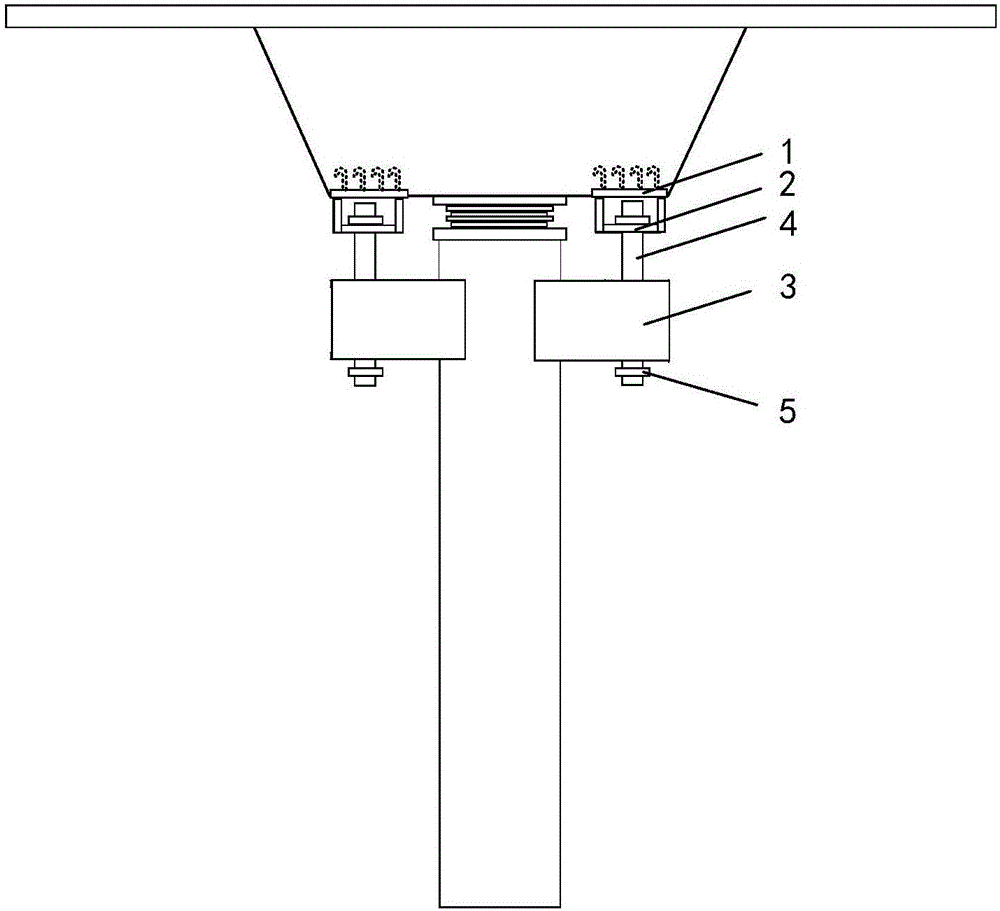

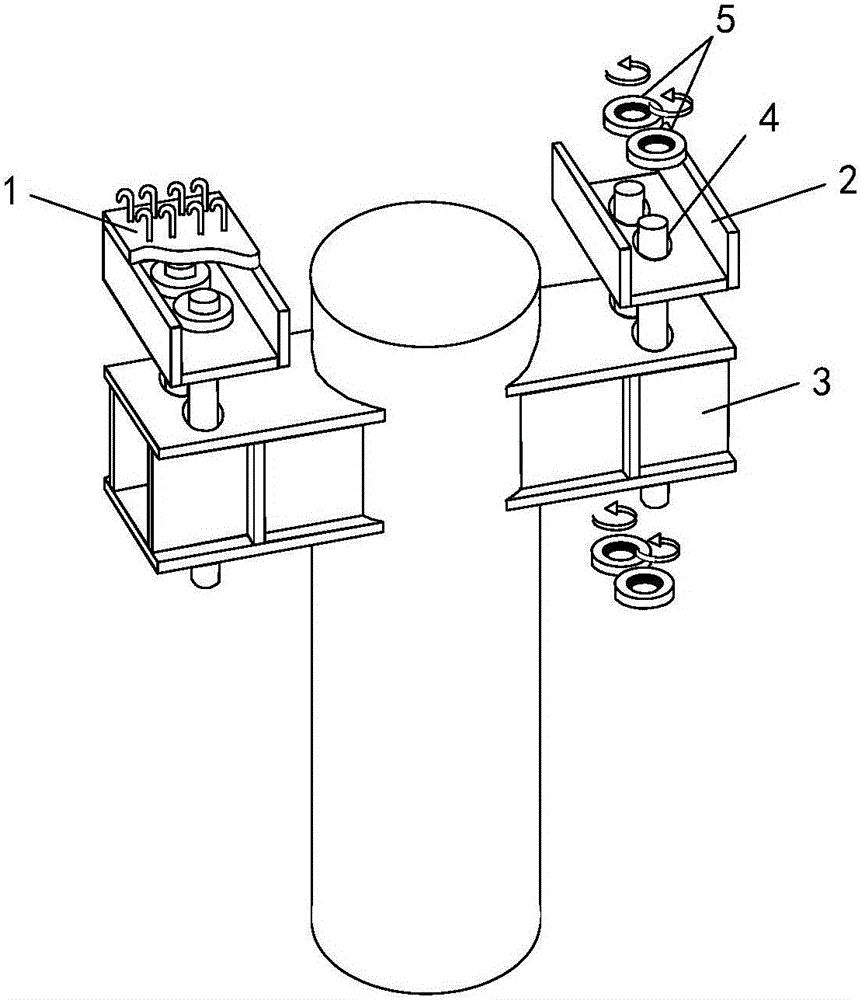

[0024] As shown in Figure 1, the structure for preventing bridge lateral overturning according to the present invention includes embedded steel plates 1 at the bottom of the bridge deck, channel steel plates 2, corbels 3, steel anchor rods 4 and nuts 5, wherein the embedded steel plates 1 are along the transverse direction of the bridge. Arranged on both sides of the bottom of the bridge deck and firmly connected with the bridge deck through anchors, the vertical flange plate of the channel steel plate 2 is connected with the embedded steel plate 1 by welding to form a hollow box-shaped structure, which can accommodate the nut 5 Arrange and screw. The corbel 3 can be a steel corbel, as shown in Figure 1(a), or a reinforced concrete corbel, as shown in Figure 1(b).

[0025] As shown in Figure 2, the horizontal web of the channel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com