System and method for automatically generating CO2 foam and exploiting coalbed methane in huff-puff mode underground

A technology of coalbed methane and foam, which is applied in the field of underground self-generated CO2 foam huff and puff mining of coalbed methane, can solve the problems of smaller effective seepage pores, lower coal seam permeability, matrix expansion effect, etc., to achieve easy control of dosage and time, and convenient Relocation and transportation, the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

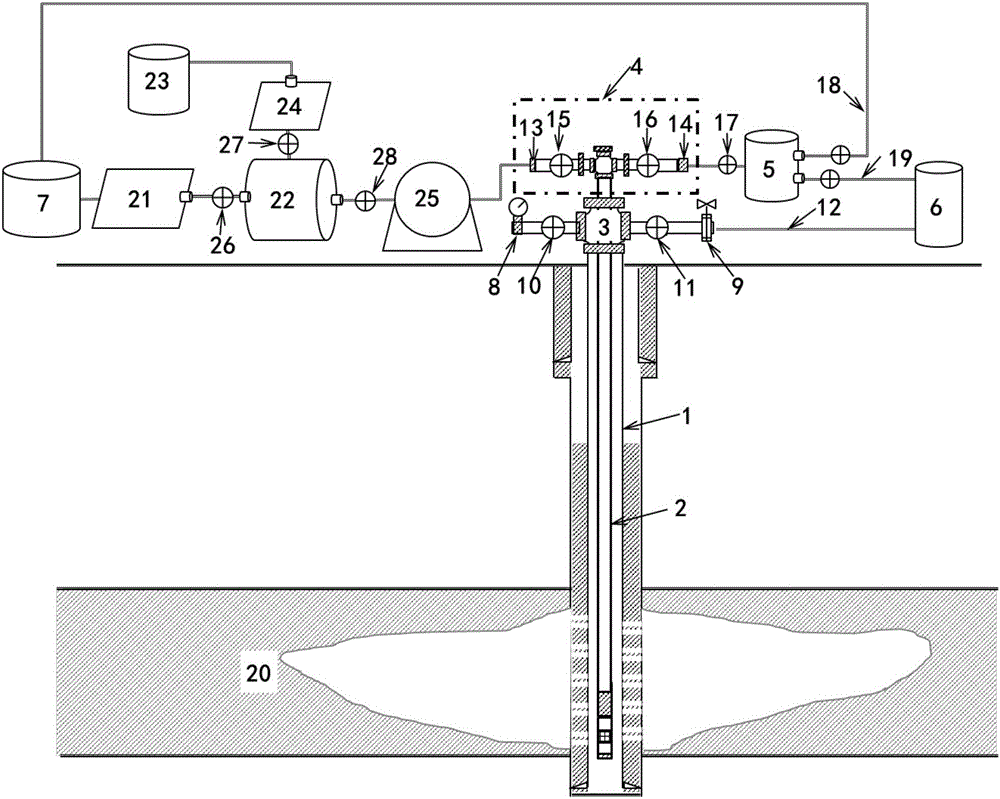

[0013] Such as figure 1 As shown, in the prior art, the coalbed methane well generally adopts the two-hole structure scheme, from the outside to the inside, followed by the well wall, the cement sheath between the surface casing and the well wall, the surface casing, the production casing and the well wall. Cementing cement sheath between well walls, production casing 1, annular space between production casing 1 and oil pipe and pump hanging tool 2, as well as oil pipe and pump hanging tool 2; the surface system of coalbed methane well includes: big four-way 3, Wellhead gas tree 4, gas-water separator 5, gathering and transportation device 6, water storage device 7 and related pipeline joints, data acquisition and control instrument tools.

[0014] The outlets on both sides of the large cross 3 are respectively externally connected to the casing pressure gauge 8 and the casing throttle valve 9, and the casing pressure gauge 8 is used to monitor the pressure change of the annul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com