A Portable Small Lightweight High Power Hydraulic Station

A light-weight, hydraulic station technology, applied in the field of hydraulic stations, can solve problems such as heat dissipation difficulties and inability to use, and achieve the effects of reducing layout size, compact structure, and reducing volume and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

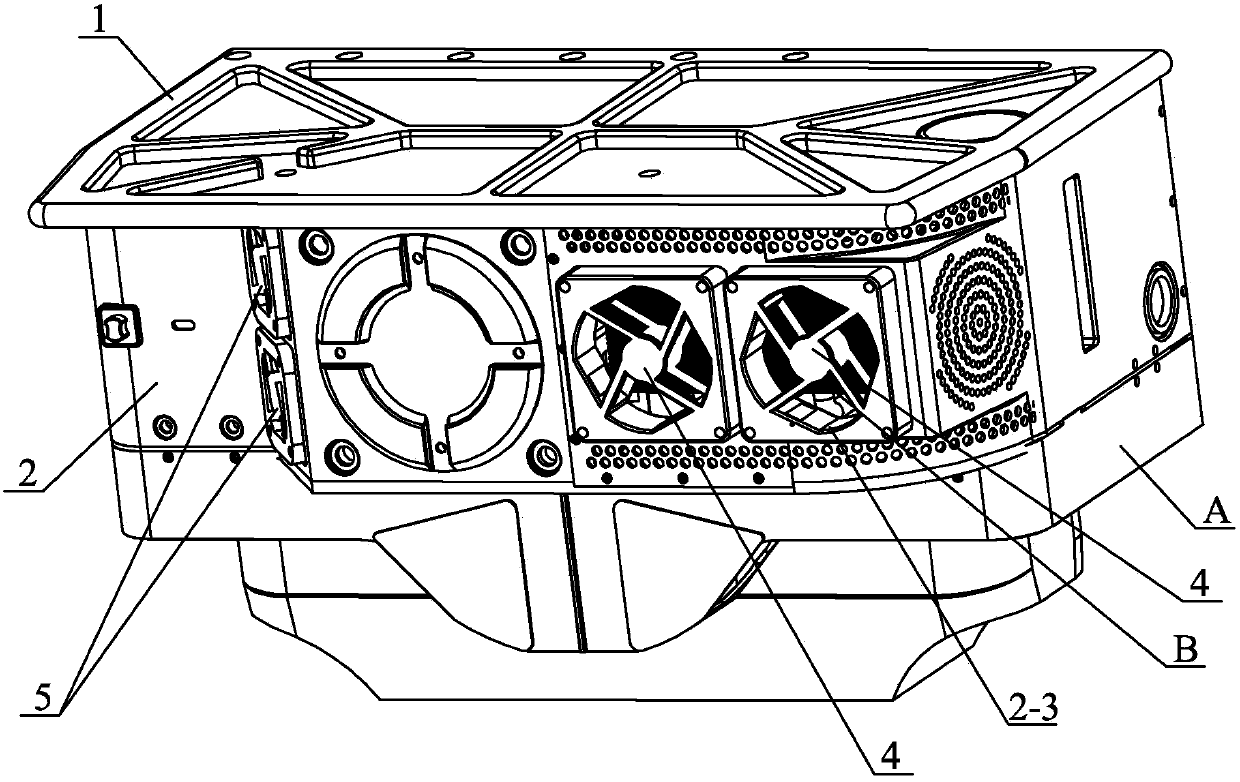

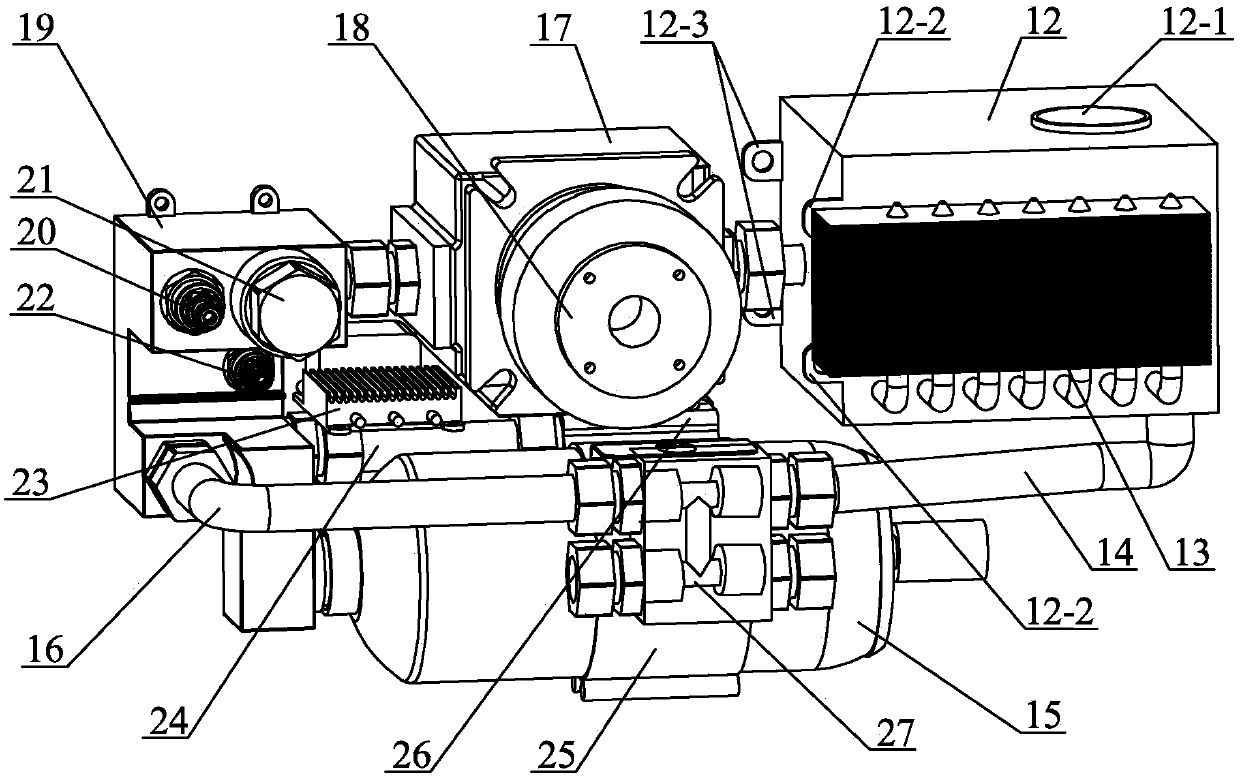

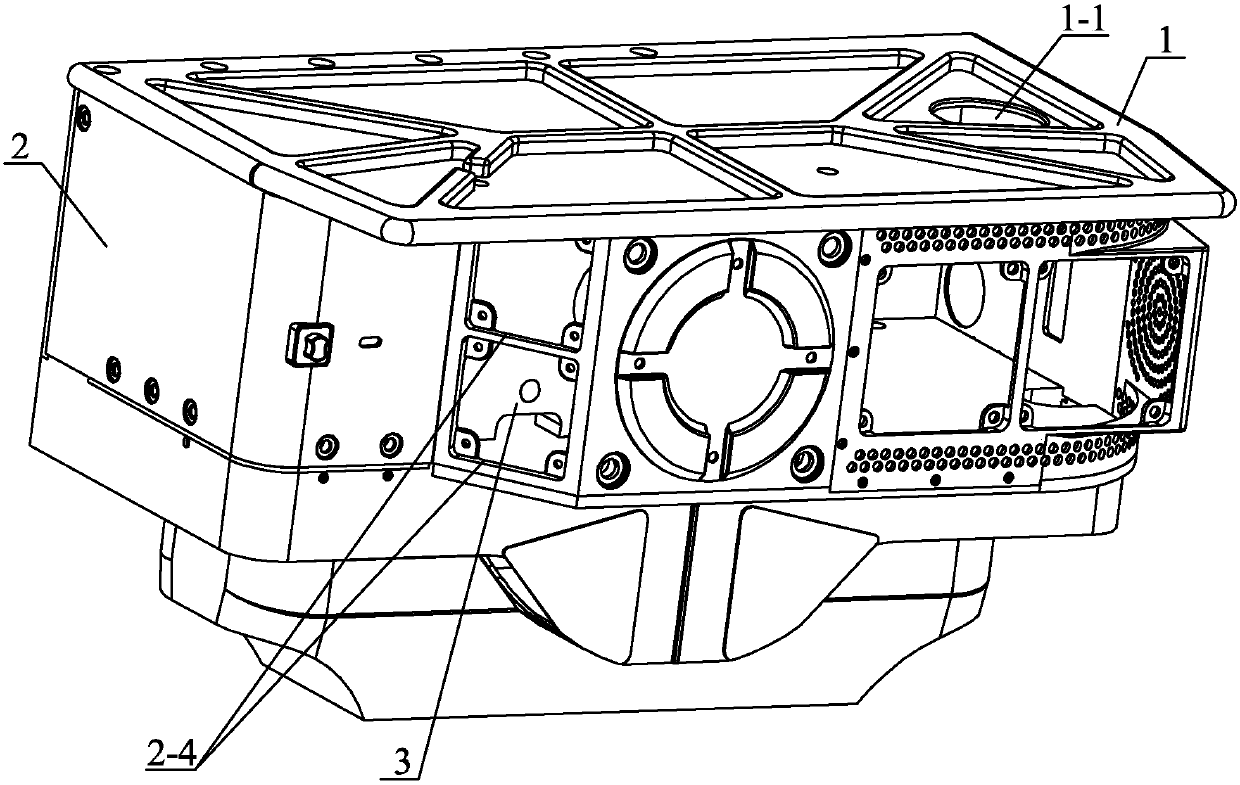

[0013] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment. This embodiment includes a hydraulic assembly shell A and a hydraulic assembly B. The hydraulic assembly B includes a fuel tank 12, a heat pipe radiator 13, a fuel tank return pipe 14, an accumulator 15, a valve return pipeline 16, a hydraulic pump 17, Outer rotor motor 18, integrated valve 19, overflow valve 20, filter 21, pressure sensor 22, ESC 23, high pressure oil pipeline 24, high pressure oil outlet valve 26, low pressure oil return valve 27, heat pipe radiator 13 fixed installation In the fuel tank 12, one end of the fuel tank return pipe 14 is welded and fixed to the fuel tank 12, and the other end of the fuel tank return pipe 14 is connected to the joint of the low-pressure oil return valve 27, and the oil outlet end of the fuel tank 12 is connected to the oil inlet port of the hydraulic pump 17 through the joint , the hydraulic pump 17 is connected to the outer rotor mot...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 2 The present embodiment will be described. The KV value of the outer rotor motor 18 in the present embodiment is 120KV. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 2 The present embodiment will be described. The oil tank 12 of the present embodiment is provided with an oil filling port 12-1. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com