Combustion air supply system in biomass combustion furnace, combustion furnace and heating device

A technology of biomass combustion furnace and gas supply system, which is applied in the field of combustion gas supply system, combustion furnace and heating equipment, which can solve the problems of affecting combustion efficiency, blockage of combustion furnace, waste of resources, etc., and achieve the effect of efficient working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

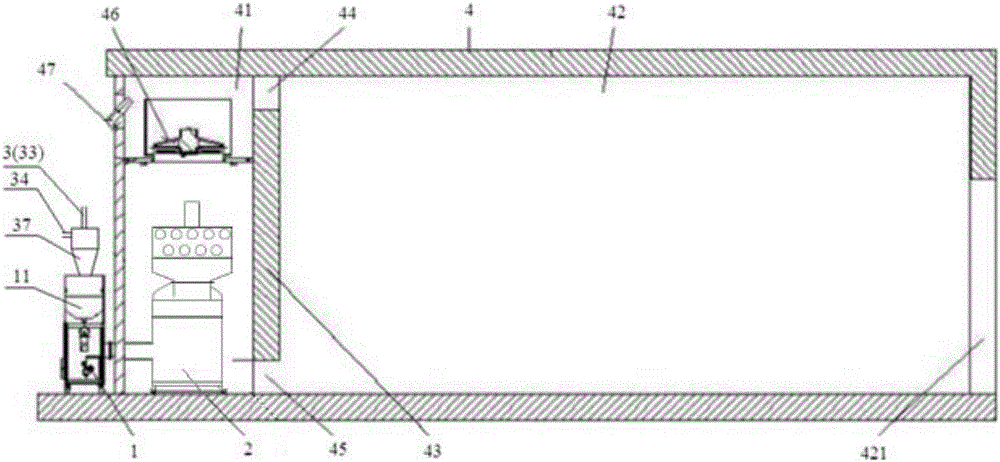

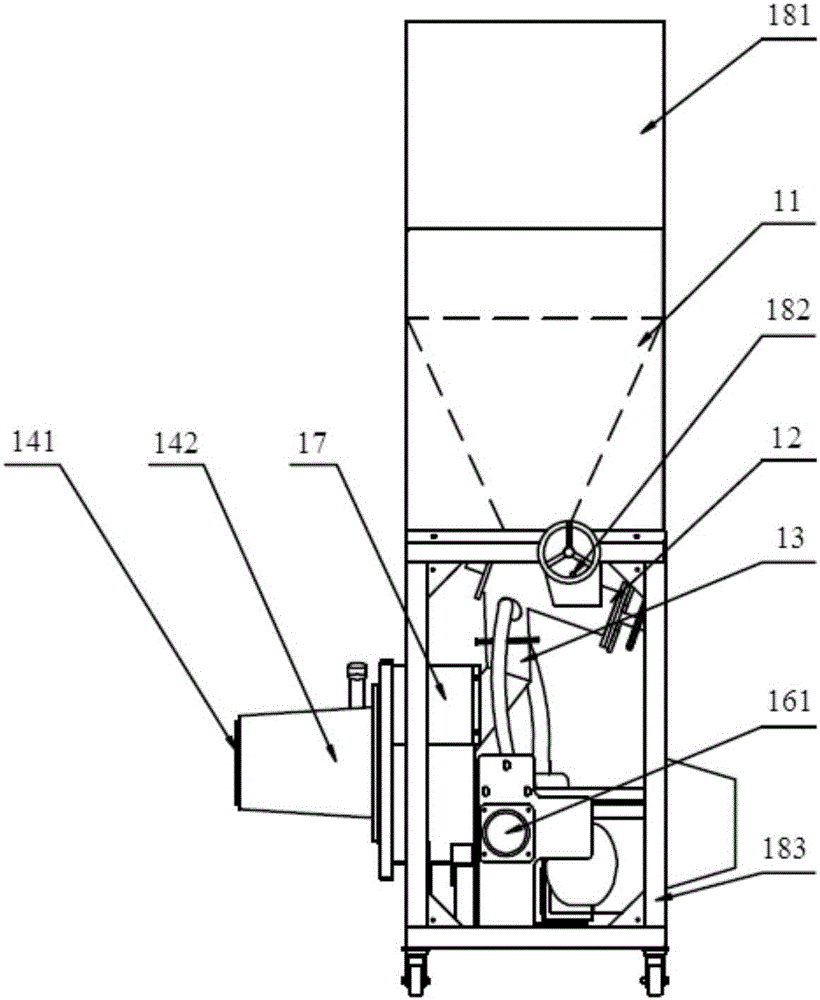

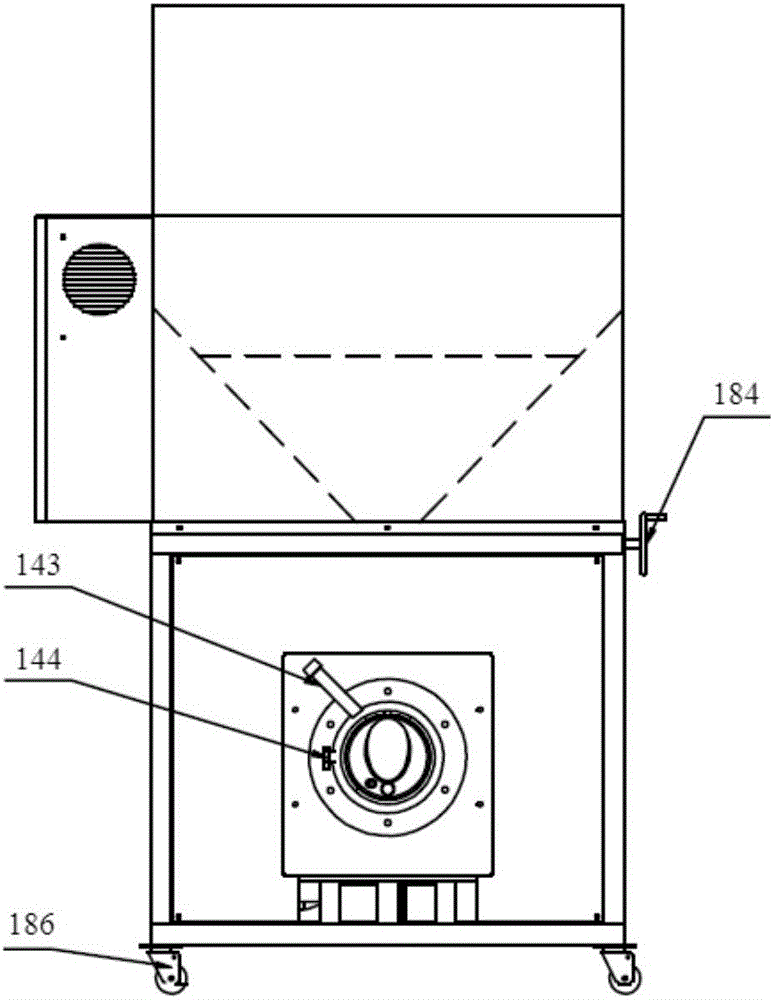

[0041] The present invention will describe the heating equipment and its components in detail with reference to the accompanying drawings, but the protection scope of the present invention is not limited thereto.

[0042] 1. Combustion furnace in heating equipment:

[0043] 1) Biomass pellet fuel

[0044] The applicable fuel of the present invention mainly includes biomass particles using sawdust, tobacco stalks, soybean stalks, rice husks and the like as raw materials. The biomass particles are cylindrical particles crushed and extruded (or compressed) with a particle size (diameter) of 3 to 20 mm, preferably 5 to 10 mm, and a particle length generally less than 6 cm, preferably 2 to 10 mm in length. 5cm. The density of the biomass pellet fuel is > 1g / cm 3 , preferably with a density of 1.05 to 1.3 g / cm 3 .

[0045] 2) Furnace nozzle in the combustion furnace

[0046] Such as Figure 1~4 As shown, the present invention firstly provides a burner nozzle in a biomass comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com