Drying equipment for textile printing and dyeing

A textile printing, dyeing and drying technology, applied in lighting and heating equipment, drying, drying machines, etc., can solve the problems of low drying efficiency, affecting the drying/drying efficiency of printed and dyed textiles, and easy to produce swimming migration, etc., to improve Good drying quality and drying efficiency, good drying and color fixation results, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

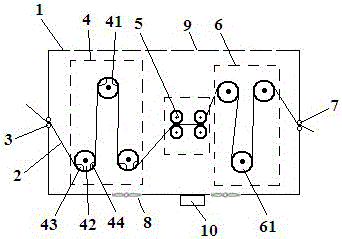

[0012] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 The shown textile printing and dyeing drying equipment includes a drying shell 1, which is characterized in that the drying shell 1 includes a feed roller 3, a guide roller group 4, and a pressure roller in sequence according to the flow direction of the printing dye 2 5. Cooling roller group 6 and pulling roller 7, the feed roller 3, guide roller group 4, pressure roller 5, cooling roller group 6 and pulling roller 7 are arranged horizontally, the inside of the drying shell 1 A microwave generator 11 is provided on the inner wall of the guide roller group 4 , an air inlet device 8 is provided at the bottom of the drying housing 1 , and a plurality of exhaust holes 9 are provided at the top of the drying housing 1 .

[0013] Further, the guide roller set 4 includes a plurality of guide roller bars 41 arranged in parallel, and the guide roller bars 41 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com