Lubricating oil composition

A lubricating oil composition and composition technology, applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve problems affecting the retention of friction characteristics, not paying enough attention, affecting the wear prevention of lubricating oil compositions, etc. , to achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

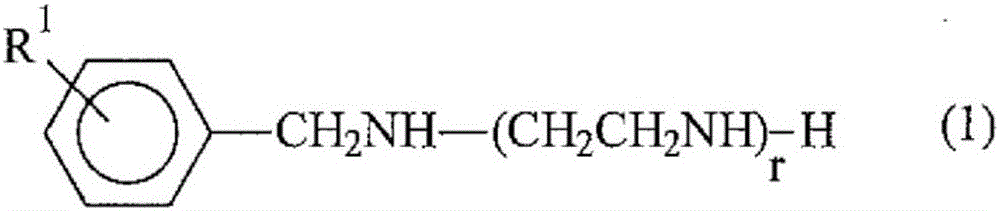

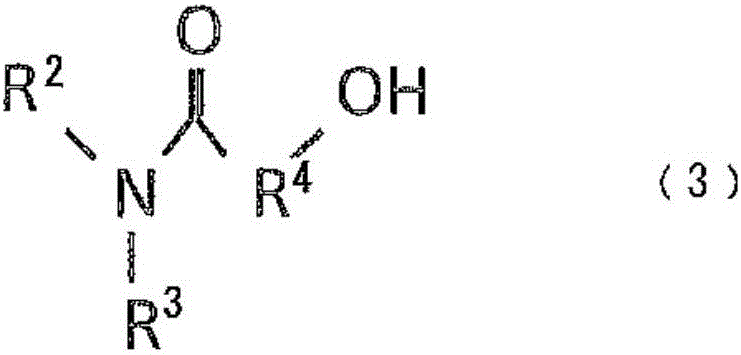

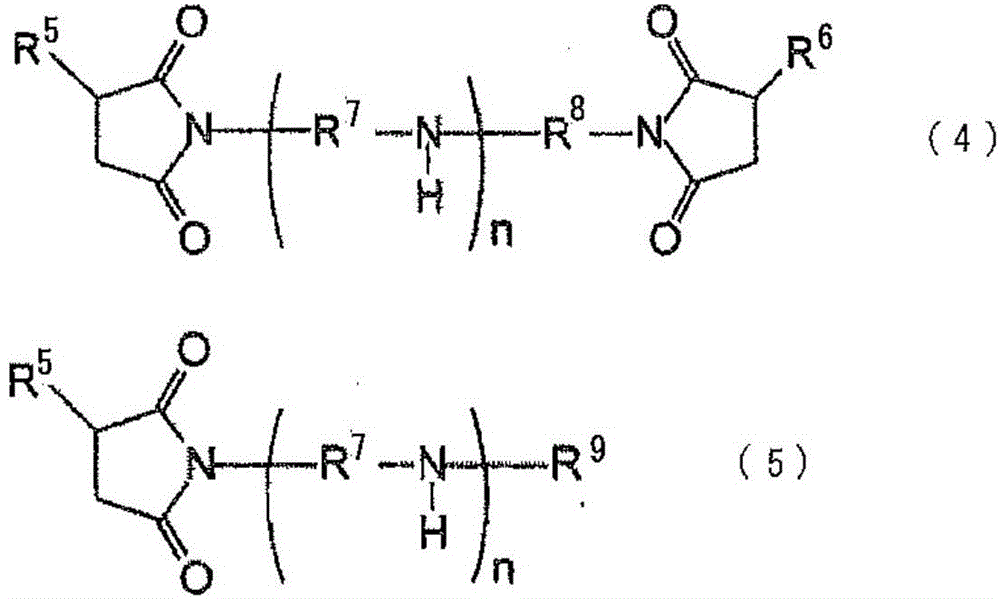

Method used

Image

Examples

Embodiment 1 to 11 and comparative example 1 to 8

[0143] Lubricating oil compositions of Examples 1 to 11 shown in Table 1 were prepared (prepared to have 5.5mm 2 / s 100°C Kinematic Viscosity) and the lubricating oil compositions of Comparative Examples 1 to 8 shown in Table 2 for comparison, and the evaluation involves when they were newly mined and after being subjected to the oxidation stability test and the rubber immersion test (1) wear resistance and (2) seizure prevention (extreme pressure). The results are also shown in Tables 1 and 2. The proportion of each base oil is based on the total mass of the oil, and the amount of each additive is based on the total mass of the composition.

[0144] (1) Abrasion prevention

[0145] The abrasion resistance was evaluated as follows: The wear scar diameter was measured by sliding the ball back and forth for one hour in the Shell four-ball test according to ASTM D4172 under the conditions of a load of 392N, a rotation speed of 1900rpm, and an oil temperature of 100°C.

[0146]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com