Industrial sulfur tail gas desulfurization process

A desulfurization process and tail gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of failing to meet emission requirements, high fuel consumption, poor economy, etc., and achieve low operating costs and no fuel consumption , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

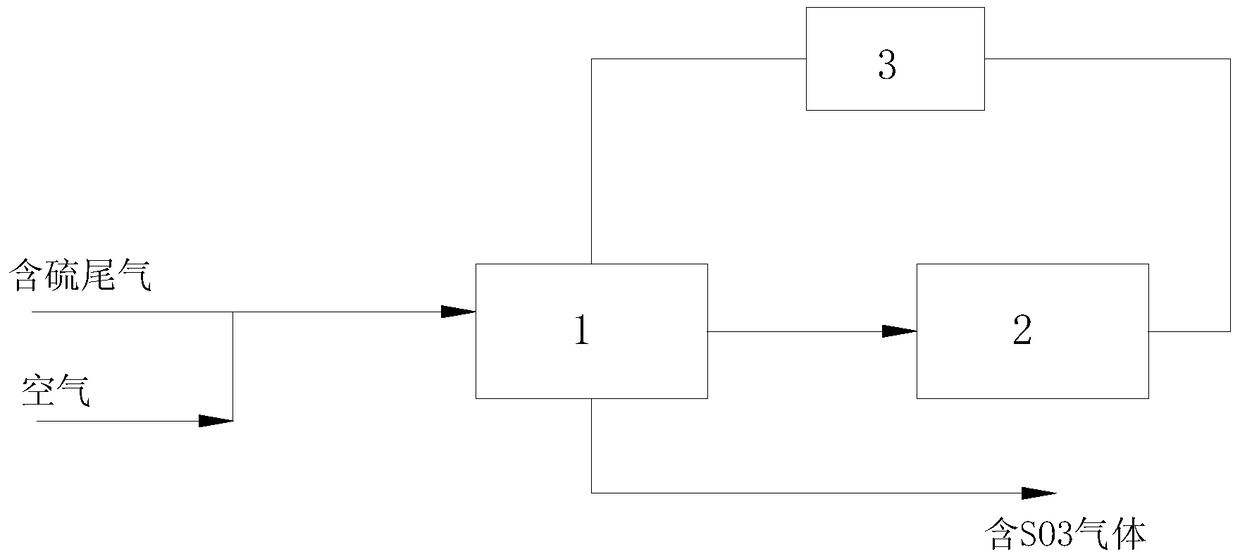

[0024] Such as figure 1 As shown, the sulfur-containing tail gas enters the SCO reactor, the inlet material temperature is controlled at 203°C, the outlet temperature is controlled at 312°C, and the operating pressure is controlled at 2.4Kpa. The purified tail gas is sent to the subsequent acid / ammonium sulfate unit or others.

[0025] It has been determined that the content of other components in the net exhaust gas is: SO 2 ≤150mg / Nm 3 ; where SO 2 The conversion rate is ≥96%.

Embodiment 2

[0027] Such as figure 1 As shown, the sulfur-containing tail gas enters the SCO reactor, the inlet material temperature is controlled at 235°C, the outlet temperature is controlled at 340°C, and the operating pressure is controlled at 8.5Kpa. The purified tail gas is sent to the subsequent acid / ammonium sulfate unit or others.

[0028] It has been determined that the content of other components in the purified tail gas is: SO 2 ≤150mg / Nm 3 ; where SO 2 The conversion rate is ≥96%.

Embodiment 3

[0030] Such as figure 1 As shown, the sulfur-containing tail gas enters the SCO reactor, the inlet material temperature is controlled at 272°C, the outlet temperature is controlled at 369°C, and the operating pressure is controlled at 15.8Kpa. The purified tail gas is sent to the subsequent acid / ammonium sulfate unit or others.

[0031] It has been determined that the content of other components in the purified tail gas is: SO 2 ≤150mg / Nm 3 ; where SO 2 The conversion rate is ≥96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com