Hot continuous rolling mill steel strip threading deviation tension control method and control system thereof

A technology of tension control and hot continuous rolling mill, applied in tension/pressure control, metal rolling, metal rolling, etc., can solve problems such as deviation tension control, and achieve the effect of precise control and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

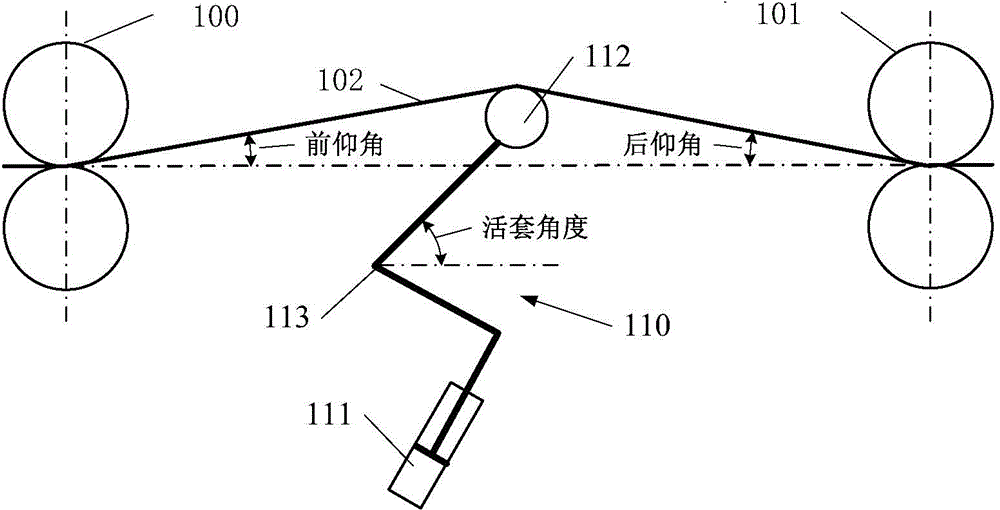

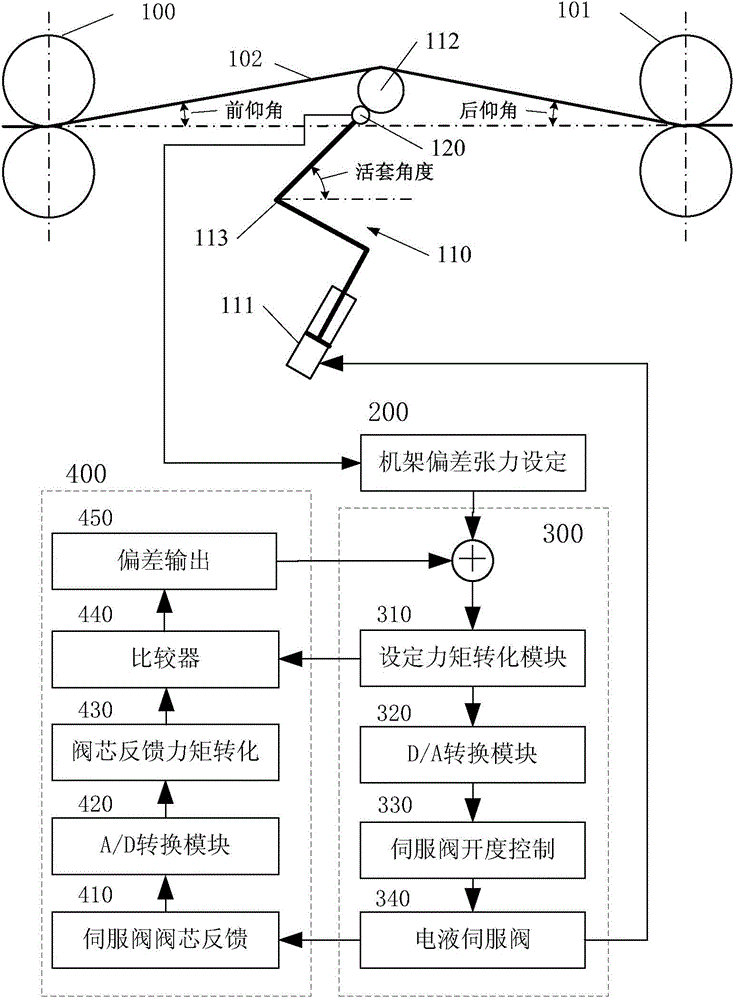

Method used

Image

Examples

Embodiment

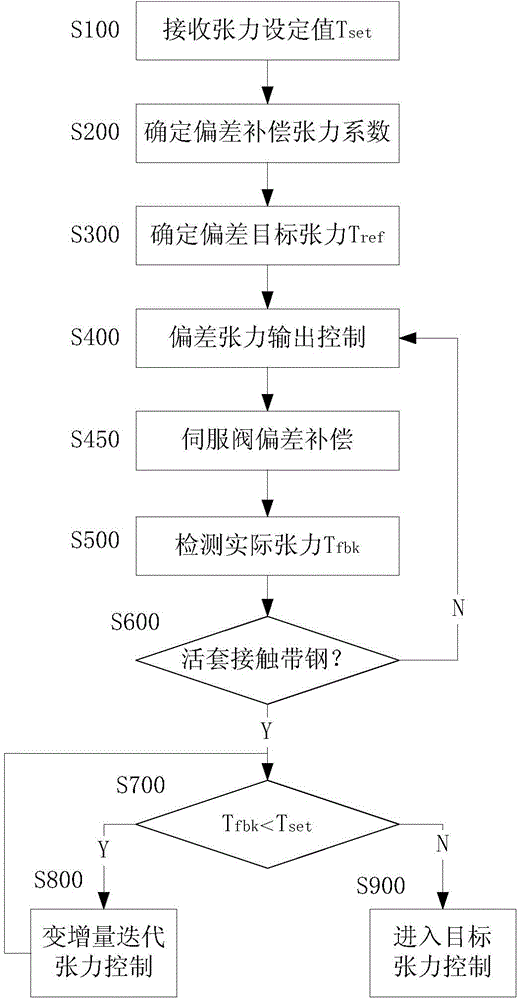

[0091] This embodiment takes the 6# looper 6 of a certain hot rolling mill as an example, and specifically describes the control process of the method for controlling the threading deviation tension of the hot rolling mill according to the present invention.

[0092] S100: The frame deviation tension setting unit 200 receives the strip steel parameters and the tension setting value T of the current frame from the superior process control computer L2 set , the strip steel parameters include the finished product thickness, finished product width and steel grade of the strip steel, which are stored in the data cache; in the present embodiment, the steel strip specification is 1.82*1050mm, the steel grade code is 3, and the process control computer L2 Set tension setpoint T set = 20 MPa.

[0093] S200: Look up Table 1, Table 2 and Table 3 according to the above-mentioned strip steel parameters, and calculate the deviation tension compensation coefficient as

[0094] t'=t' 1 ×t′...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com