Multilayer composite copper foil forming equipment

A forming equipment, copper foil technology, applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems of ineffective use of factory space, elongated process time, space increase, etc., to shorten the process required The effect of time, low manufacturing cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

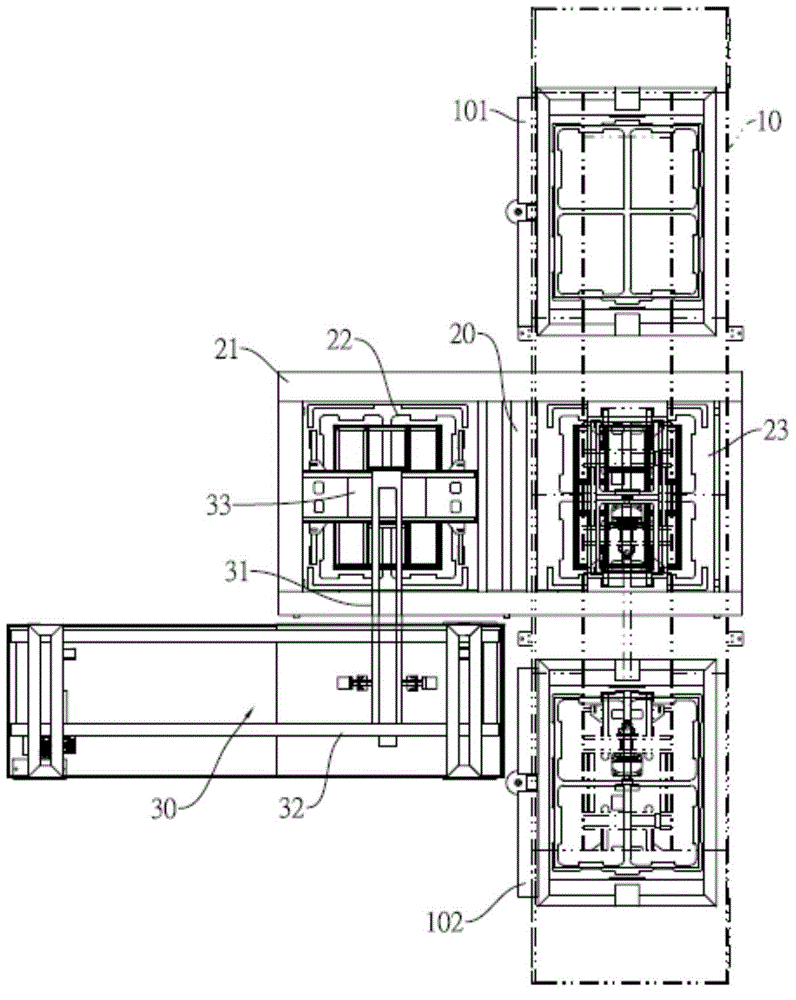

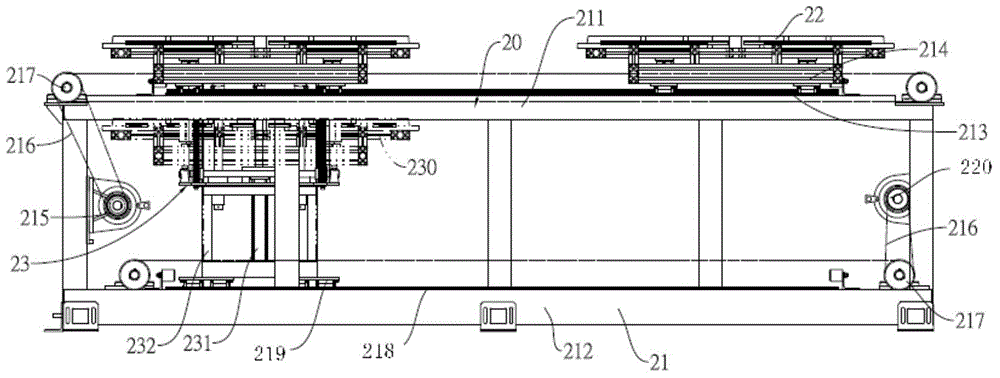

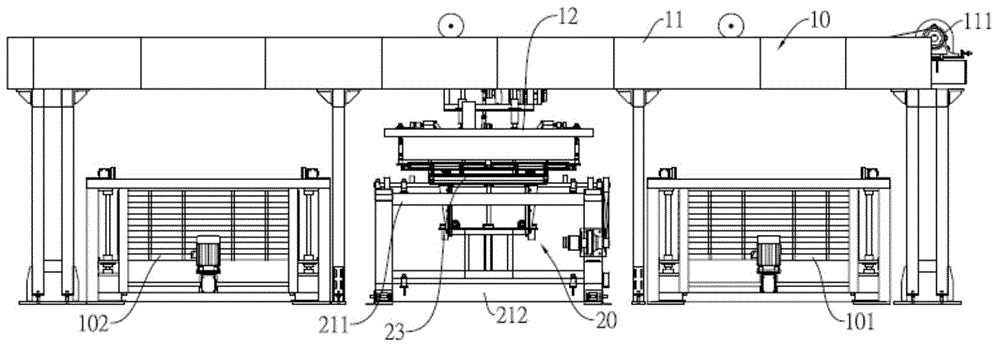

[0030] Embodiment: a multi-layer copper foil forming equipment, including feeding device 10, exchange device 20, conveying device 30 and clamping device (not shown in the figure), feeding device 10 includes a traverse track 11 and a suction The crane 12 is provided with a drive motor 111 on the traversing track 11, and the power output of the drive motor 111 is given to the suction crane 12. The traversing track 11 is moved, and the first material rack 101 and the second material rack 102 are respectively arranged at the bottom of the two ends of the traversing track 11. The first material rack 101 is stacked with a number of trays loaded with dielectric materials. The second material rack 102 is used to stack the trays without dielectric material. The suction hoist 12 can absorb the dielectric material on the first material rack 101. The material of the dielectric material can be PP or glass fiber. The suction hoist 12. The empty trays on the first shelf 101 can also be sucke...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap