Microbiological corrosion resisting duplex stainless steel

A duplex stainless steel, microorganism-resistant technology, applied in the field of duplex stainless steel, can solve the problems of affecting the marine ecological balance, unfriendly environment, poor durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

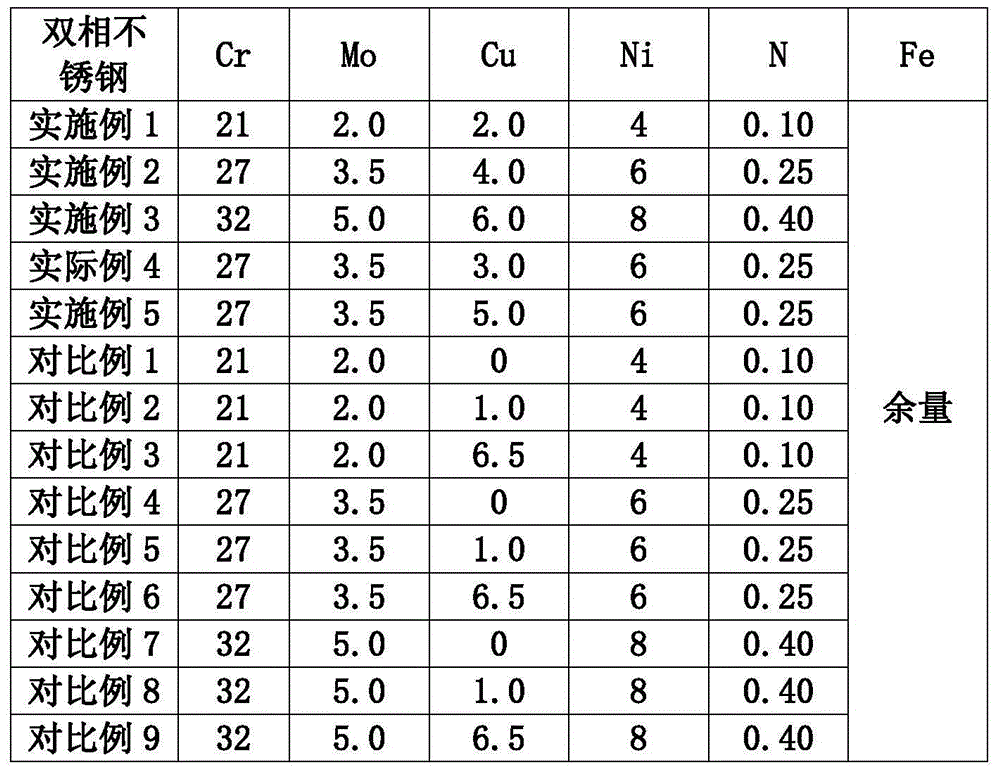

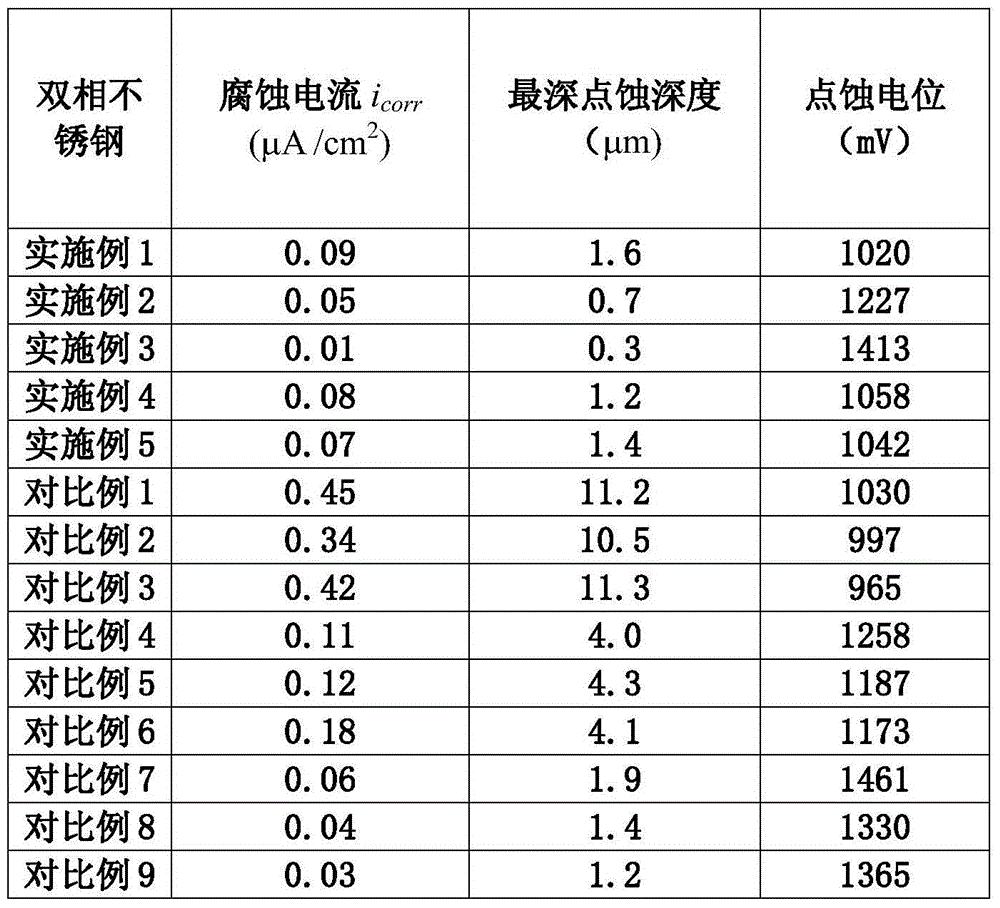

[0014] Examples 1-3, Comparative Examples 1-9 The chemical composition of the duplex stainless steel is shown in Table 1.

[0015] Table 1 embodiment and comparative example duplex stainless steel alloy chemical composition (wt%)

[0016]

[0017] All the duplex stainless steels in the examples and comparative examples adopt the preferred heat treatment, and the specific heat treatment system is: heat preservation at 1050-1080° C. for 2 hours, air cooling, aging at 580-620° C. for 5 hours, and air cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com