Photosensitive module and manufacturing method thereof

A photosensitive module and module technology, applied in the photosensitive field, can solve the problem that the thinness of electronic photosensitive imaging products cannot be further improved, and achieve the effects of reducing the probability of impurities contaminating the image sensor, reducing the failure rate, and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

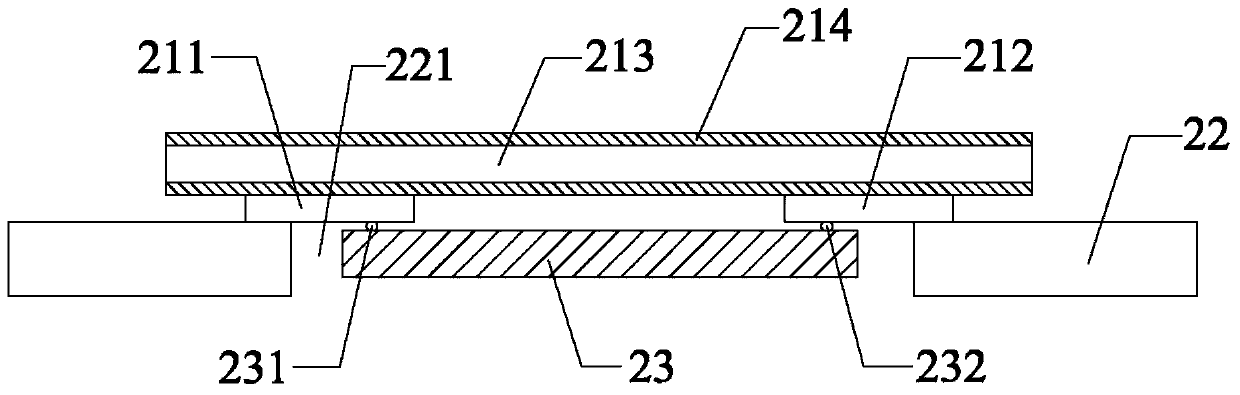

[0060] Please refer to figure 2 , Embodiment 1 of the present application provides a photosensitive module, including:

[0061] A printed circuit board 22, including a receiving part 221;

[0062] An image sensor 23, the image sensor is at least partially housed in the housing part, so that the distance between the printed circuit board and the packaging component is smaller than the thickness of the image sensor;

[0063] The packaging component is connected with the printed circuit board and used for packaging the image sensor.

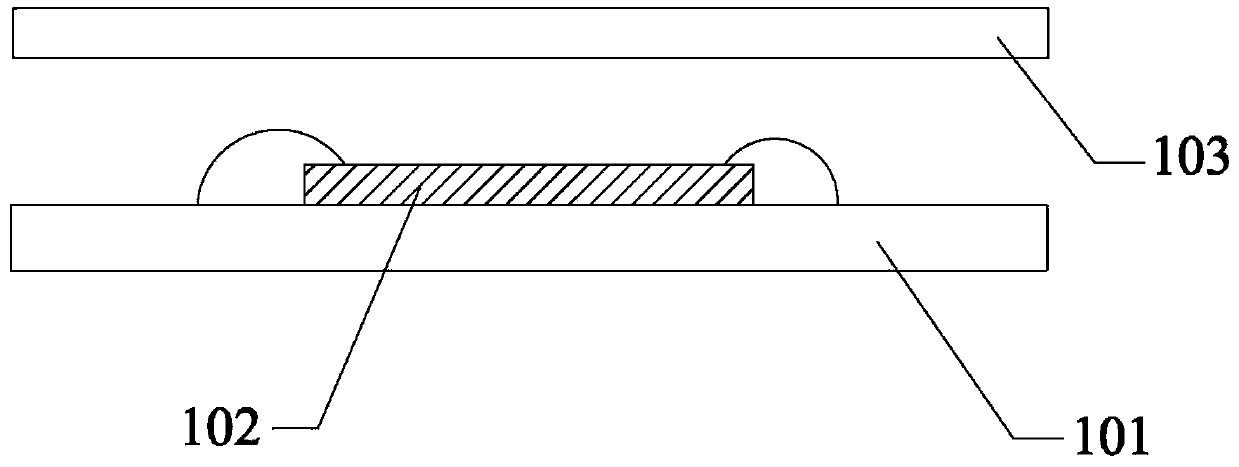

[0064] Since the receiving part is provided on the printed circuit board, and the image sensor is at least partially housed in the receiving part, when the photosensitive module in the embodiment of the present application is placed horizontally and the glass cover is located above the printed circuit board, The image sensor is at a position slightly lower than the printed circuit board relative to the glass cover. It can be seen that the technic...

Embodiment 2

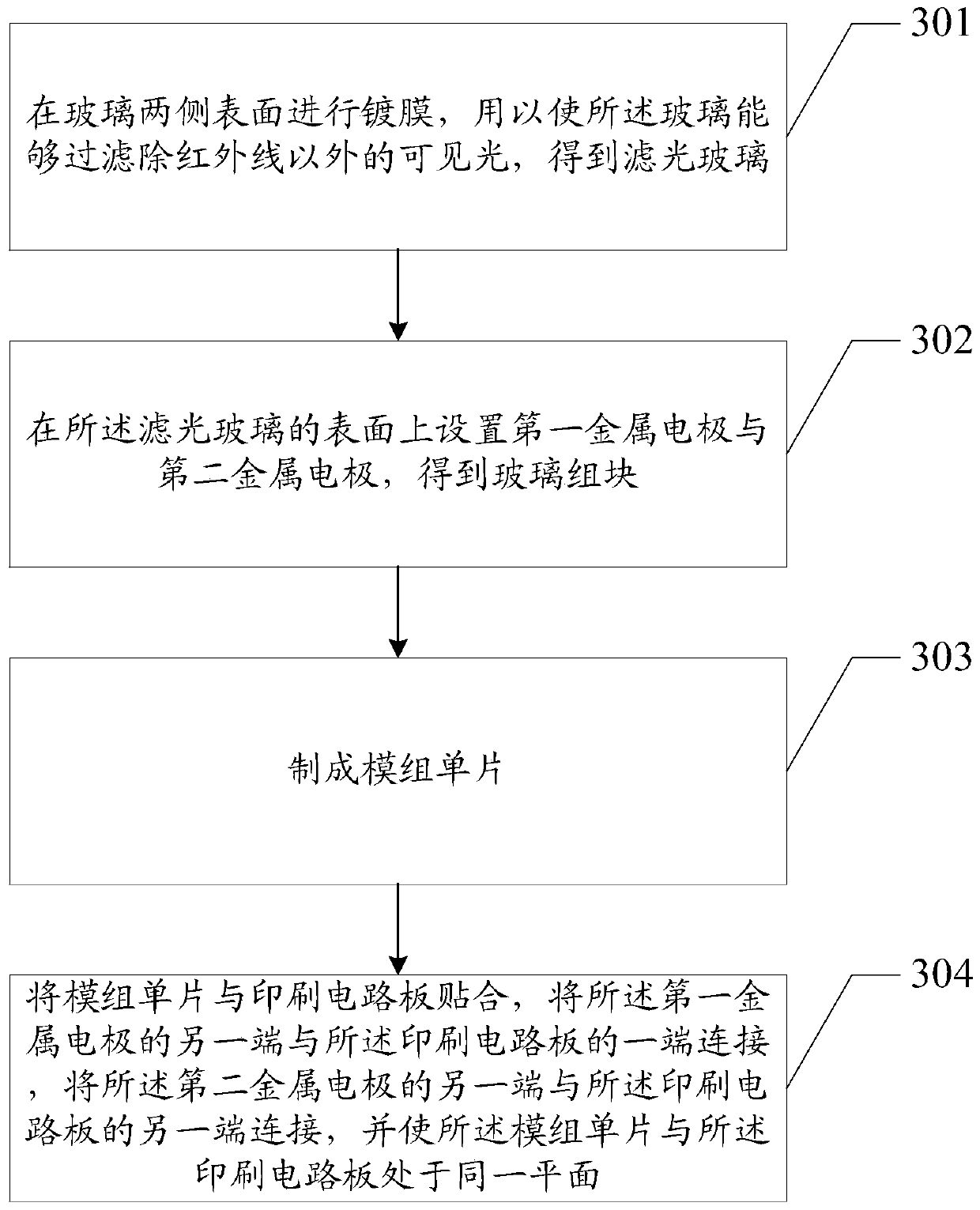

[0081] Please refer to image 3 , Embodiment 2 of the present application provides a method for manufacturing the photosensitive module as claimed in claim 1, comprising:

[0082] Step 301: coating the surfaces of both sides of the glass to enable the glass to filter visible light except infrared rays to obtain filter glass;

[0083]Step 302: setting a first metal electrode and a second metal electrode on the surface of the filter glass to obtain a glass cover;

[0084] Step 303: attach the image sensor to the glass cover, make the first metal electrode and the second metal electrode between the image sensor and the glass cover, and place the first metal The first end of the electrode is connected to the first end of the image sensor, the first end of the second metal electrode is connected to the second end of the image sensor, and the glass cover plate is cut according to predetermined specifications into modular monolithic pieces; or,

[0085] cutting the glass cover acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com