Multi-sawtooth disk cutting blade

A technology of cutting blades and sawtooth, applied in the field of multi-serrated disc cutting blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

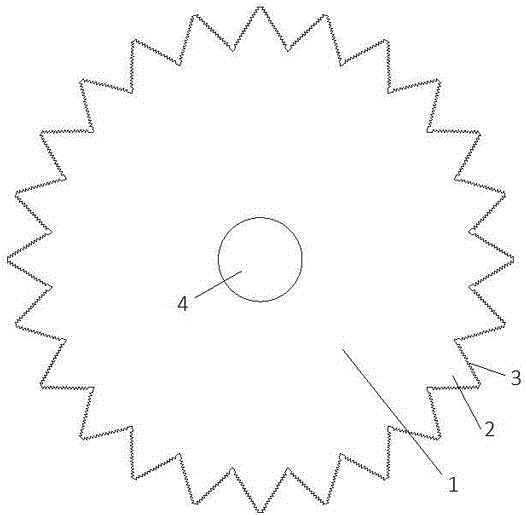

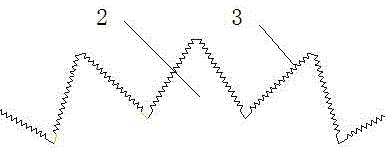

[0068] A multi-serrated disc cutting blade, comprising a disc-shaped metal base 1 with a central hole 4, the outer circumference of the metal base 1 is provided with a number of evenly distributed cutting saw teeth 2, and each edge of the cutting saw teeth 2 is provided There are several cutting small sawtooths 3 evenly distributed, and the thickness of the tooth back of the cutting sawtooth 2 is greater than the thickness of the tooth tip;

[0069] The adjacent cutting saw teeth 2 have an angle of 15°, and the adjacent small cutting saw teeth have a pitch of 5 mm; the cutting saw teeth 2 have a tip angle of 15°, and the cutting small saw teeth 3 have a tip angle of 30°.

[0070] The cutting saw body is an isosceles trapezoid.

[0071] Its production process includes:

[0072] Step 1: Heat the steel plate of 80CrV2 high speed steel to 1100~1200°C, keep it warm at 900~800°C for 30~45 minutes, complete the primary annealing, and then place the steel plate after the primary anne...

Embodiment 2

[0103] Embodiment two On the basis of embodiment one, the quenching agent formula is changed:

[0104] 40 parts of water-soluble polyethers;

[0105] 10 parts of ethylene glycol;

[0106] 10 parts of sodium chloride;

[0107] 7 parts of zinc chloride;

[0108] 3 parts of sebacic acid;

[0109] 5 parts of adipic acid;

[0110] 3 parts of linoleic acid;

[0111] 5 parts of monoethanolamine;

[0112] 4 parts of sodium nitrite;

[0113] Diatom pure 6 parts.

Embodiment 3

[0115] Embodiment three On the basis of embodiment one, the quenching agent formula is changed:

[0116] 50 parts of water-soluble polyether;

[0117] 20 parts of ethylene glycol;

[0118] 5 parts of sodium chloride;

[0119] 10 parts of zinc chloride;

[0120] 5 parts of sebacic acid;

[0121] 1 part of adipic acid;

[0122] 5 parts of linoleic acid;

[0123] 7 parts of monoethanolamine;

[0124] 4 parts of sodium nitrite;

[0125] Diatom pure 10 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com