A kind of rubidium sulfate doping improved titanium-based tiO2 film photocatalyst preparation method

A photocatalyst, rubidium sulfate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor photocatalytic effect, inability to absorb visible light, etc., to improve utilization efficiency, improve light Catalytic degradation efficiency and effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

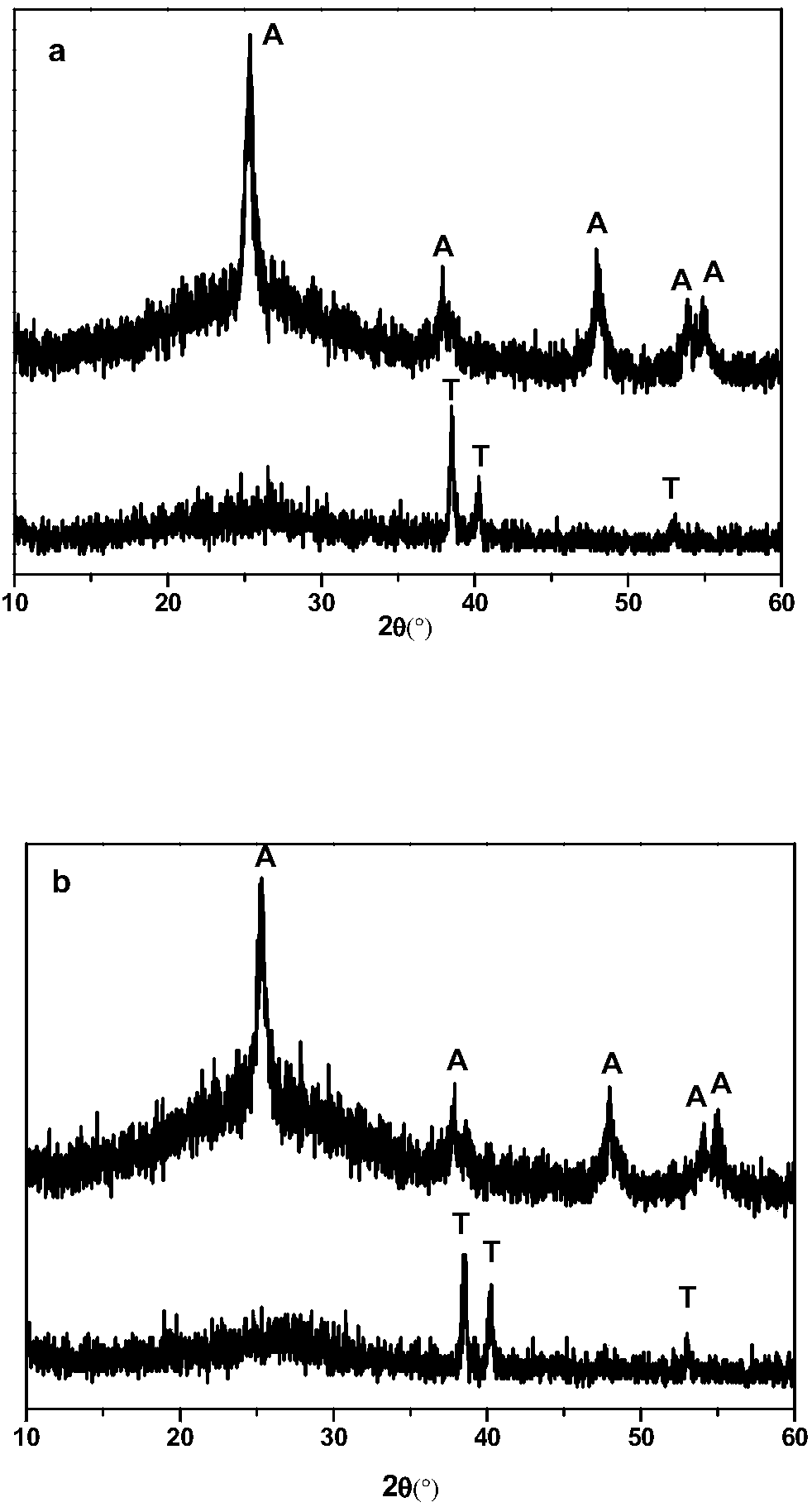

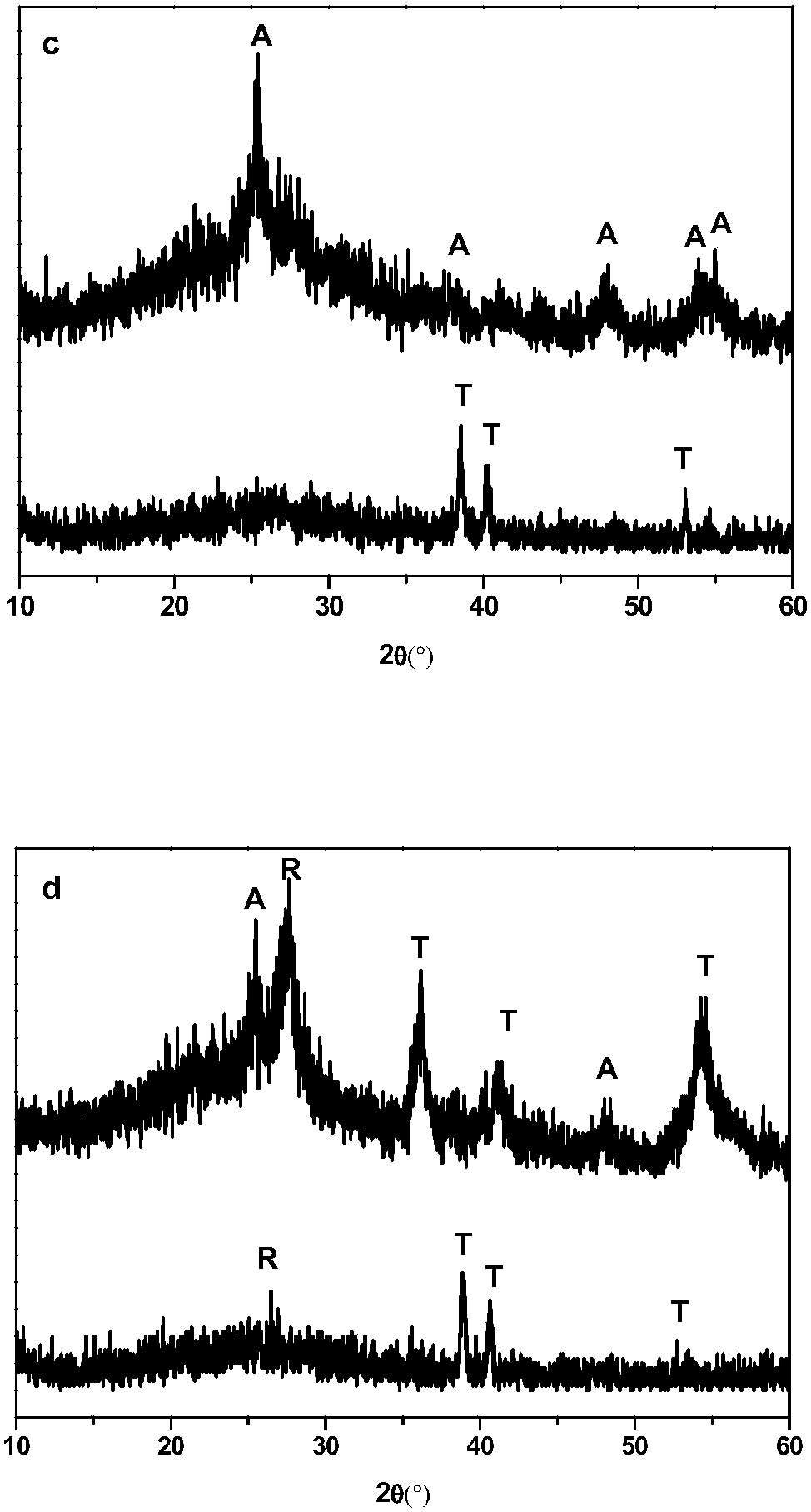

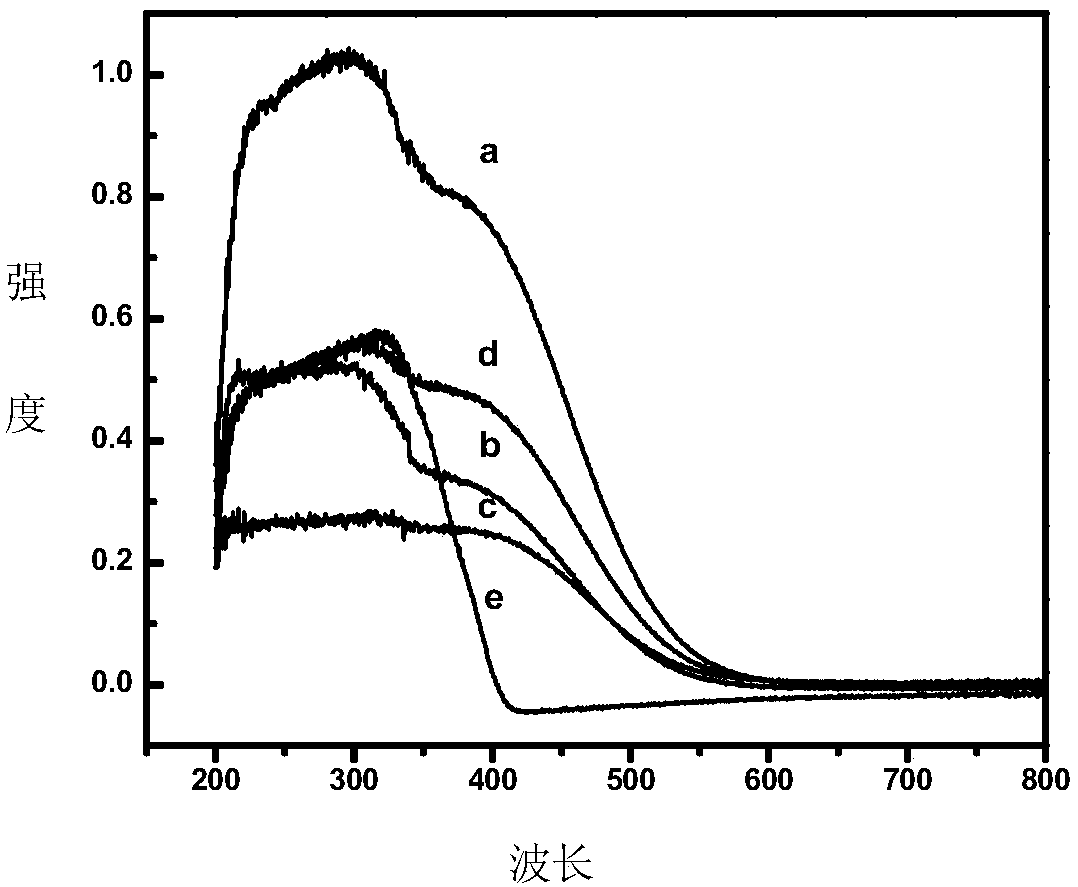

[0042] Rubidium Sulfate Doped Modified Titanium-Based TiO 2 Thin-film photocatalyst material, synthesized by in-situ growth method, doped with Rb 2 SO 4 , for TiO 2 The surface structure of the sheet is modified, and the original TiO 2 A layer of oxide film is formed on the surface of the sheet, and the film is composed of microsphere structure, and it is applied to photocatalytic degradation of organic dyes.

[0043] Rubidium sulfate-doped modified titanium-based TiO as described in this paper 2 The preparation method of thin film photocatalyst material, comprises the following steps:

[0044] Step 1: Titanium Polishing

[0045] The titanium sheet is first physically polished, and the titanium sheet is polished with 600Cw, 800Cw, 1000Cw, and 1200Cw sandpaper, and cut into a uniform size of 3cm×1.5cm; then the above titanium sheet is chemically polished, and the physical polished Titanium sheet immersed in HF and HNO 3 Polishing in a polishing solution with a volume rat...

Embodiment 2

[0056] Rubidium Sulfate Doped Modified Titanium-Based TiO 2 Thin-film photocatalyst material, using in-situ growth synthesis method, using hydrothermal synthesis method, doped with Rb 2 SO 4 , for TiO 2 The surface structure of the sheet is modified, and the original TiO 2 A layer of oxide film is formed on the surface of the sheet, and the film is composed of microsphere structure, and it is applied to photocatalytic degradation of organic dyes.

[0057] Rubidium sulfate-doped modified titanium-based TiO as described in this paper 2 The preparation method of thin film photocatalyst material, comprises the following steps:

[0058] Step 1: Titanium Polishing

[0059] The titanium sheet is first physically polished, and the titanium sheet is polished with 600Cw, 800Cw, 1000Cw, and 1200Cw sandpaper, and cut into a uniform size of 3cm×1.5cm; then the above titanium sheet is chemically polished, and the physical polished Titanium sheet immersed in HF and HNO 3 Polishing in ...

Embodiment 3

[0070] Rubidium Sulfate Doped Modified Titanium-Based TiO 2 Thin-film photocatalyst material, using in-situ growth synthesis method, using hydrothermal synthesis method, doped with Rb 2 SO 4 , for TiO 2 The surface structure of the sheet is modified, and the original TiO 2 A layer of oxide film is formed on the surface of the sheet, and the film is composed of microsphere structure, and it is applied to photocatalytic degradation of organic dyes.

[0071] Rubidium sulfate-doped modified titanium-based TiO as described in this paper 2 The preparation method of thin film photocatalyst material, comprises the following steps:

[0072] Step 1: Titanium Polishing

[0073] The titanium sheet is first physically polished, and the titanium sheet is polished with 600Cw, 800Cw, 1000Cw, and 1200Cw sandpaper, and cut into a uniform size of 3cm×1.5cm; then the above titanium sheet is chemically polished, and the physical polished Titanium sheet immersed in HF and HNO 3 Polishing in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com