Rare earth Tb doped bismuth vanadate photocatalyst and preparation method thereof

A photocatalyst and bismuth vanadate technology, which is applied in the field of rare earth Tb-doped bismuth vanadate photocatalyst and its preparation field, can solve problems such as complicated methods, and achieve the effect of simple and mild preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and ammonium metavanadate (NH 4 VO 3 ) in a mol ratio of 1:1, take by weighing an appropriate amount of bismuth nitrate pentahydrate and ammonium metavanadate, be dissolved in the nitric acid solution of 6mol / L and the sodium hydroxide solution of 0.5mol / L in concentration respectively, then use Stir with a magnetic stirrer to fully dissolve the two solutions, thereby obtaining colorless and transparent solution A and solution B respectively. The concentration of solution A is 0.5mol / L, and the concentration of solution B is 0.2mol / L.

[0027] Slowly add solution A to solution B dropwise, and continue to stir with a magnetic stirrer so that the two solutions of A and B are evenly mixed. In the process of gradually dropping solution A into solution B, the liquid will turn yellow when it comes into contact with it. As the amount of solution B dripped increases, the color change phenomenon of the mixed solution is as ...

Embodiment 2 to Embodiment 6

[0029] The doping methods of each embodiment are the same, and the molar ratios of terbium to bismuth vanadate in Examples 2 to 6 are 4:100, 6:100, 8:100, 10:100, and 12:100 in sequence.

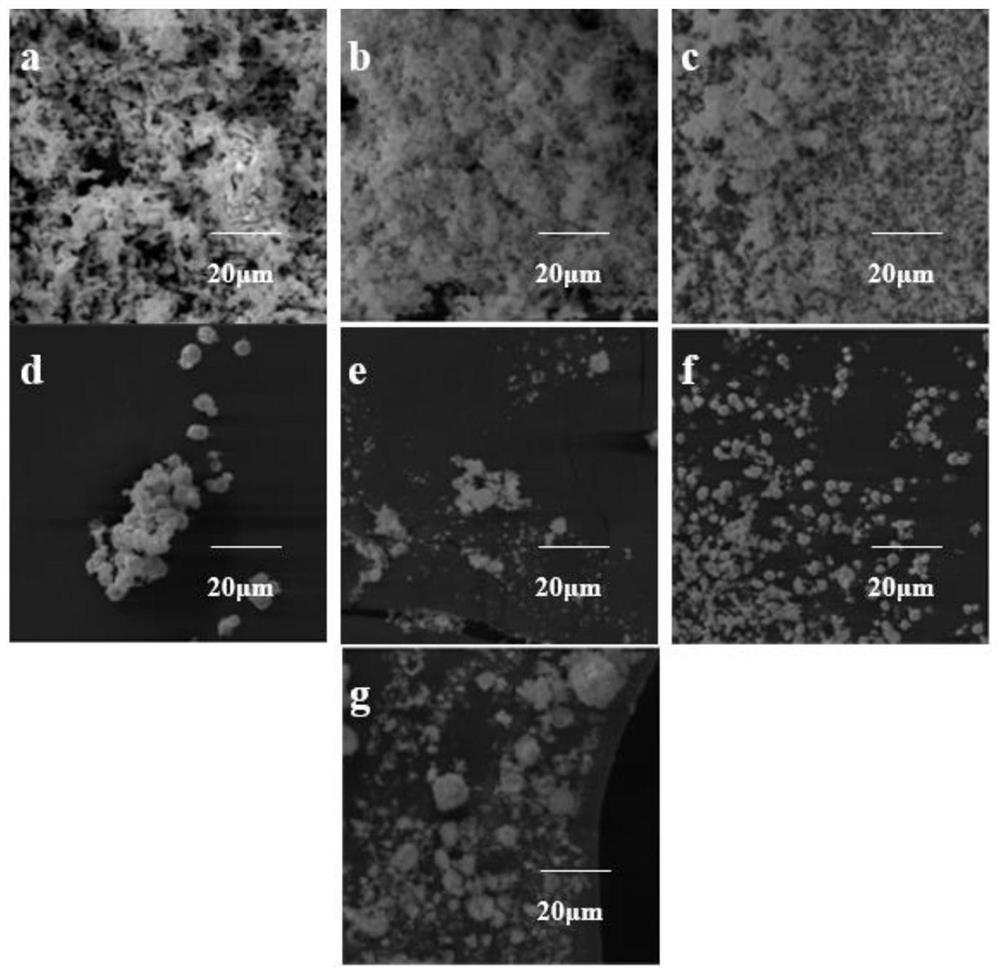

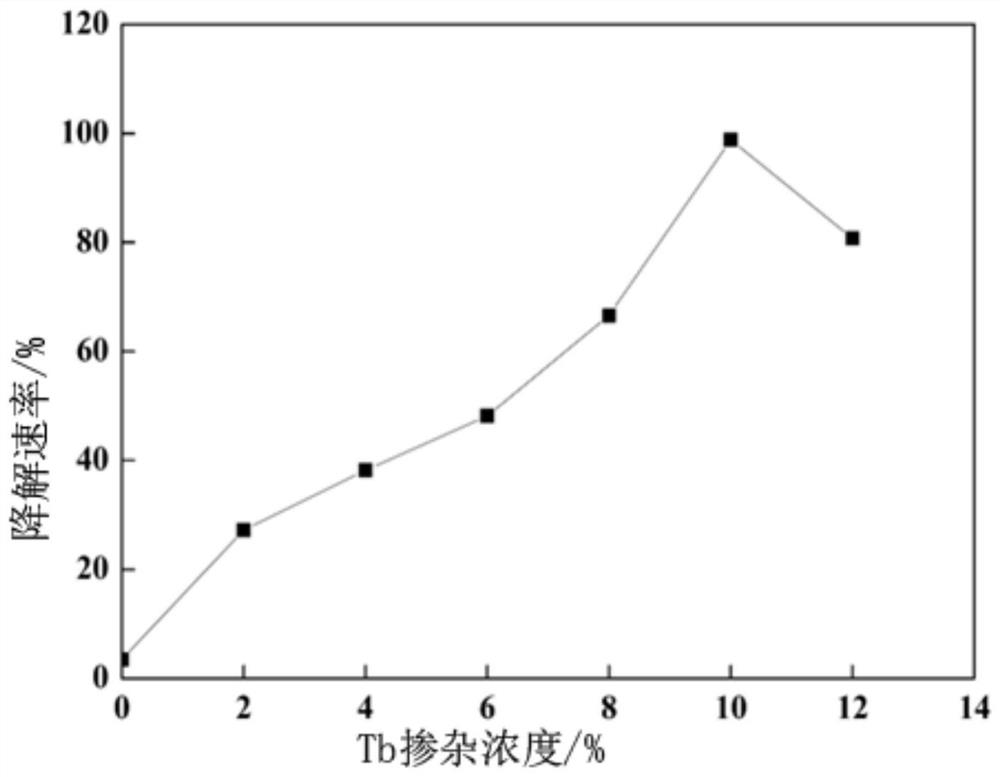

[0030] The samples obtained from Example 1 to Example 6 and 0-doped pure BiVO 4 The structure of the sample is analyzed by X-ray diffractometer; the microscopic morphology of the sample is observed by scanning electron microscope; the specific surface area and average particle size are tested by Malvern laser particle size analyzer. The test of the sample adopts ultraviolet-visible spectrophotometer to test the absorbance, and calculates the photodegradation efficiency.

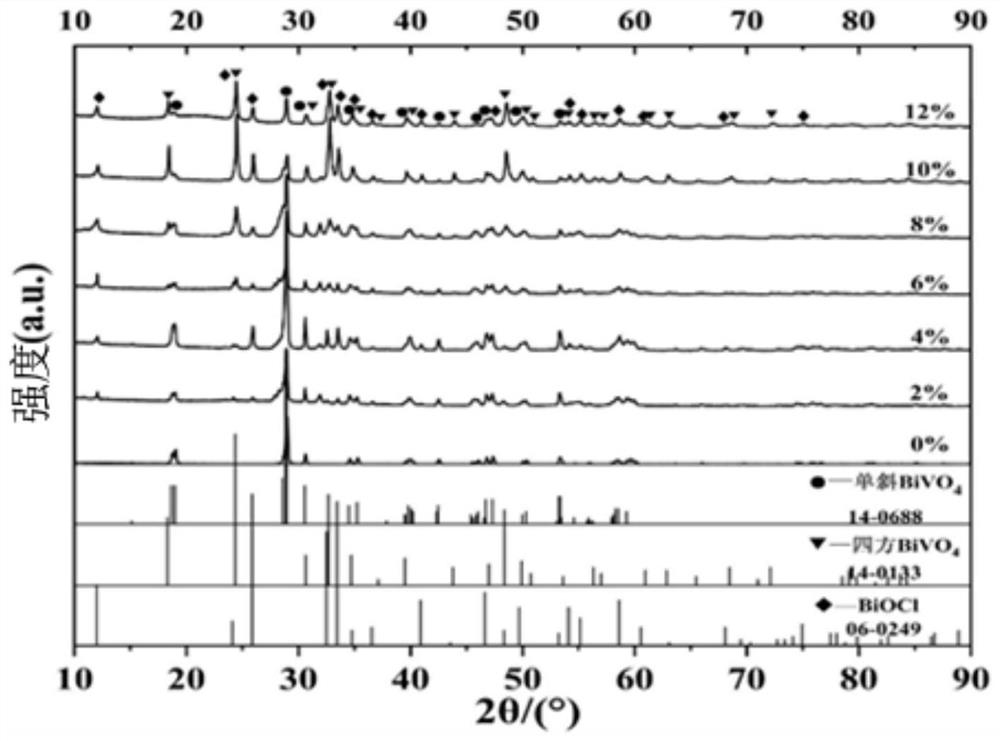

[0031] structural analysis

[0032] The structure of 7 samples was analyzed by X-ray diffraction (D8, Advanle1), the diffraction target was CuKα (λ=0.15056nm), the power was 40kV×50mA, the sampling width was 0.05°, and the scanning angle (2θ) range was 10° ~90°, the test is carried out at room temperature (25°C).

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com